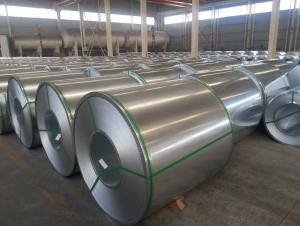

High Quality prepainted steel coil of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Standard: | AISI,ASTM,BS,DIN,GB,JIS | Grade: | PPGI | Thickness: | 0.1-20mm,0.18-1.25mm |

| Place of Origin: | Tianjin China (Mainland) | Brand Name: | cnbm | Model Number: | PPGI |

| Type: | Steel Plate | Technique: | Cold Rolled | Surface Treatment: | Galvanized |

| Application: | Ship Plate | Special Use: | High-strength Steel Plate | Width: | 1000-1800mm |

| Length: | as your requirement | note: | we can supply MTC | inspection: | we can accept third party inspection |

| packing: | standard seaworty packing | delivery time: | within 7-25 days | payment terms: | TT,LC |

| quality: | NO.1 | price: | competive | stock: | yes |

Packaging & Delivery

| Packaging Detail: | exporting seaworthy package |

| Delivery Detail: | 15-25days |

Specifications

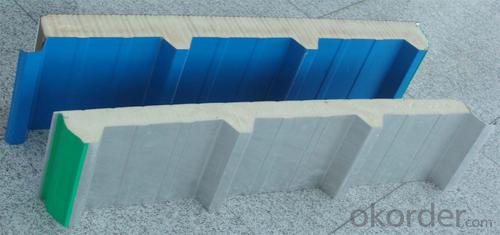

High Quality prepainted steel coil

1.Thickness:0.18-1.25mm

2.Width:800,900,1000,1250mm

3.Process:hot rolled and co

High Quality prepainted steel coil | |

Thickness | 0.18-1.25 mm |

Width | 700-1250 mm |

Coil ID | 508mm/610mm |

Standard | AISI, ASTM, BS, DIN, GB, JIS |

Material | DX51D+Z, SGCC, DX51D+AZ,SPCC-1B |

Zinc coating | 60-180g/M2 |

Painting thickness | 20-25um |

Colors | All Colors available. Color shades |

End | Threading ,coupling and with plastic caps protected |

Payment | TT ,L/C |

Packing | Standard seaworthy packing or as required |

Market | Mild east, North/South America, Europe, Asia,Africa etc |

Certificate | BV,SGS,MTC ,ISO9001:2000, |

Delivery time | Within 7-10 days |

- Q: I'm a big fan of stainless steel and sterling silver, but not of the humidity of the country I'm in. Therefore I sweat more. Gross, I know. I'm buying a necklace chain for my ring.So does sweat contribute to tarnishing of silver and steel? The real kind?

- steel shouldn't really tarnish, it rusts and moisture increases that. Silver tarnishes when exposed to air and sulfur. Moisture increases the process a bit, but it happens anyway. Sweat is not gross, it's a necessary function of your body, otherwise you would die. A lot of sports people wear jewelry and they sweat a lot. If you wear the jewelry all the time, that will prevent the tarnish a bit. If you take it off, clean it (water and dish washing liquid), dry it and put it in a zip lock back to keep it away from air and moisture. In the end, cleaning the jewelry is quick and easy so don't worry about it.

- Q: I'm getting new strings on my dad's old acoustic guitar so I can learn how to play it and I'm wondering if I should get nylon or steel strings. Are there any major differences between the two aside from the nylon strings being easier on your fingers? Like do the Nylon strings sound different?

- If it's a classic guitar, then you should get nylon strings, because you can't use steel strings on a classic guitar, and you can't use nylon strings on an acoustic guitar , I would suggest that you buy a classic guitar, because it's really good for beginners.

- Q: I want to know if it is possible to make regular steel stainless.From what I understand stainless consist of chromium about 10 percent I think.Any way I'm wondering if properties can be added in a process or can this only be possible during actual manufacturing of the steel.And I'm not talking about chrome like stainless steel that's not to shiny.

- This okorder /

- Q: Are steel coils resistant to rust and corrosion?

- Yes, steel coils are resistant to rust and corrosion. Steel coils are typically made from carbon steel or stainless steel, both of which have excellent corrosion resistance properties. Carbon steel coils are often coated with a protective layer, such as zinc or a polymer coating, to enhance their resistance to rust and corrosion. Stainless steel coils, on the other hand, are inherently corrosion-resistant due to the presence of chromium, which forms a protective oxide layer on the surface of the steel, preventing rust and corrosion. However, it is important to note that the level of resistance to rust and corrosion may also depend on the specific grade and quality of the steel used in the coils, as well as the environmental conditions they are exposed to.

- Q: How many inches of steel can an AK47 using 7.62x39mm rounds penetrate through?

- It can't go through inches. It can go through up to 1/4 of an inch of plate steel but not much more. An M-16 can go through it as well and has less powder behind it but the 7.62X39 is a fat round and it takes a little more to get it through.

- Q: can anyone help me to find any webpage about lists/types of stainless steel?

- Types of stainless steel There are over 150 grades of stainless steel, of which fifteen are most common. The AISI (American Iron and Steel Institute) defines the following grades among others: - 200 Series—austenitic iron-chromium-nickel-manganese alloys - 300 Series—austenitic iron-chromium-nickel alloys Type 301—highly ductile, for formed products. Also hardens rapidly during mechanical working. Type 303—free machining version of 304 via addition of sulfur Type 304—the most common; the classic 18/8 stainless steel Type 316—Alloy addition of molybdenum to prevent specific forms of corrosion - 400 Series—ferritic and martensitic alloys.

- Q: What are the different types of steel coil storage methods?

- There are several types of steel coil storage methods, including stacking coils vertically, using coil cradles or saddles, utilizing coil racks or frames, employing coil lifters or C-hooks, and implementing automated coil storage systems. Each method is designed to accommodate different storage requirements and ensure the safety and efficient handling of steel coils.

- Q: I have my grandpa's navy knife from ww2, a mk2 combat knife i think, and i was wondering what type of steel it is made of. I'm guessing it's a high carbon steel, i'd just like to know exactly what grade.

- 1095 Steel - Easy to sharpen, plain carbon steel used in knife making. Proven to be one of the most popular steels used in KA-BAR knives. Right from the OEM site. Worked for a company that started in 1859 as a safe manufacturer. The steel recipes have not changed much from WWII (when Elliot Ness was running the company) to now. Doubt the KA-BAR recipes has changed either.

- Q: How are steel coils used in the construction of buildings?

- Steel coils are used in the construction of buildings for various purposes, primarily for structural support. These coils are typically used to create steel frames, beams, and columns that provide strength and stability to the structure. Additionally, steel coils are also used in the production of roofing materials, wall cladding, and reinforcement bars, which further enhance the durability and safety of the building.

- Q: Can steel coils be stretched?

- No, steel coils cannot be stretched as they are already tightly wound and have limited flexibility.

Send your message to us

High Quality prepainted steel coil of CNBM in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords