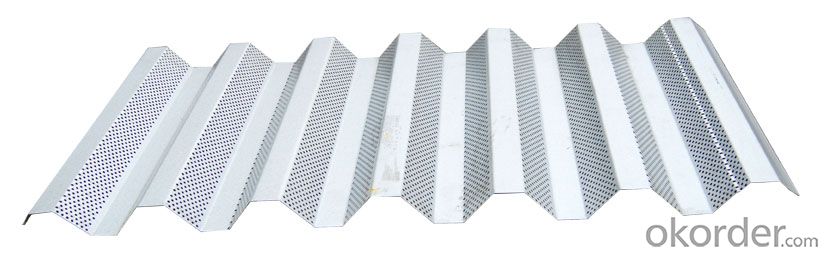

Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

Quick Details

| Standard: | Grade: | Place of Origin: | |||

| Brand Name: | Technique: | Surface Treatment: | |||

| Width: | Length: |

Packaging & Delivery

| Packaging Detail: | standard seaworthy packing |

| Delivery Detail: | 25 days |

Specifications

1.for civil building, car port, roofing, shelters, walk ways, fences & barns.

2. anti-rust.

3.good quality&service.

Color Galvanized Corrugated Steel Sheet

Typical size range

1.Thickness:0.17mm-1.0mm

2.Width:600mm-1250mm

3.Zinc coated:40g-275g

4.MOQ:25tons

Specifications

Color :RAL

Width before corrugation: 750, 900, 1000mm

Width after corrugation: 660, 800, 885mm

| Typical size range | 0.14 – 1.6mm Thick 650 – 1000mm Wide 1800 – 3600mm Length |

| Zinc coating | 20 to 180g/sqm |

| Spangle | Zero spangle, regular spangle, small spangle |

| Surface treatment | Chromate; oiling; phosphated; anti-finger print |

| Available specifications | EN 10326-2004 EN 10327-2004 JIS G3302 ASTM A653 A653M GB/T 2518-2004 |

| Steel grades | DX51D+Z; SGCC; A653 CS-B; DX53D; SGCH; SS GRADE80 |

- Q: What is the maximum temperature resistance of steel sheets?

- The maximum temperature resistance of steel sheets is dependent on the specific type of steel and its composition. Stainless steel, in general, exhibits good heat resistance and can endure temperatures up to approximately 1200 degrees Celsius (2200 degrees Fahrenheit) while maintaining its strength and structural integrity. Conversely, high carbon steels can tolerate temperatures up to around 900 degrees Celsius (1650 degrees Fahrenheit) before experiencing a decline in their mechanical properties. It should be noted that these temperature limits are approximate and subject to variation based on factors such as exposure duration, the presence of other elements or impurities in the steel, and the specific application of the steel sheets. Consequently, it is always prudent to refer to the manufacturer's specifications or conduct further research to ascertain the precise maximum temperature resistance of a specific type of steel sheet.

- Q: How do steel sheets perform in terms of weather resistance?

- Steel sheets are known for their exceptional weather resistance properties. Due to their composition and protective coatings, steel sheets are highly resistant to various weather conditions such as rain, snow, and wind. They have the ability to withstand extreme temperatures, both hot and cold, without any significant deterioration or damage. Additionally, steel sheets are also highly resistant to corrosion, making them an ideal choice for outdoor applications and areas with high humidity or saltwater exposure. The weather resistance of steel sheets helps to ensure their longevity and durability, making them a reliable option for various construction and industrial purposes.

- Q: Are steel sheets suitable for architectural mesh applications?

- Yes, steel sheets are suitable for architectural mesh applications. Steel sheets offer durability, strength, and versatility, making them an excellent choice for architectural mesh applications. They can be easily shaped, cut, and formed into various designs, allowing for the creation of intricate and aesthetically pleasing architectural mesh structures. Additionally, steel sheets can withstand harsh weather conditions and provide excellent security, making them a reliable option for architectural applications.

- Q: Are steel sheets resistant to seismic activities?

- Steel sheets can provide some level of resistance to seismic activities due to their strength and flexibility. However, their seismic resistance depends on various factors such as the thickness and quality of the sheets, the building design, and the overall structural system. Proper engineering and construction techniques, including the use of appropriate reinforcement and connections, are crucial to ensure the steel sheets effectively withstand seismic forces.

- Q: How do you prevent rusting on steel sheets?

- There are several effective measures you can take to prevent rusting on steel sheets. 1. Protective Coatings: Applying a protective coating such as paint, enamel, or powder coating creates a barrier between the steel surface and the surrounding environment. These coatings act as a shield against moisture and oxygen, preventing rust formation. 2. Galvanization: Galvanizing steel sheets involves coating them with a layer of zinc. Zinc is highly resistant to corrosion and acts as a sacrificial anode, protecting the steel underneath. This process is commonly used for outdoor applications where steel is exposed to moisture and harsh weather conditions. 3. Proper Storage: Storing steel sheets in a dry and well-ventilated area is crucial to prevent rust formation. Moisture and humidity are major contributors to rust, so it is important to keep the steel sheets away from damp or wet environments. Additionally, storing the sheets off the ground on pallets or racks can help prevent contact with moisture. 4. Regular Cleaning and Maintenance: Regularly cleaning the steel sheets with mild detergent and water can help remove any dirt, debris, or corrosive substances that may lead to rusting. It is important to dry the sheets thoroughly after cleaning to prevent moisture accumulation. 5. VCI (Volatile Corrosion Inhibitor) Packaging: Using VCI packaging materials such as VCI paper or film can be effective in preventing rust on steel sheets during storage or transportation. VCI emits corrosion-inhibiting molecules that form a protective layer on the steel surface, preventing rust formation. 6. Avoiding Contact with Water: Avoid exposing steel sheets to water or other corrosive liquids for extended periods. If the sheets come into contact with water, it is essential to dry them thoroughly as soon as possible to prevent rusting. By following these preventive measures, you can significantly reduce the risk of rust formation on steel sheets and ensure their long-term durability and performance.

- Q: Definition and application of steel sheet pile

- The steel sheet pile is a kind of edge with linkage device, and the linkage device can be freely assembled so as to make the linkageA steel structure forming a continuous tight retaining or retaining wall

- Q: What is the density of steel sheets?

- The density of steel sheets typically ranges from 7.85 to 8.05 grams per cubic centimeter (g/cm³).

- Q: Are steel sheets suitable for construction applications?

- Steel sheets are an ideal choice for construction applications due to their exceptional qualities. Renowned for their strength, durability, and versatility, steel is widely favored in the construction industry. Steel sheets find extensive use in various areas, including roofing, flooring, wall panels, structural frames, and cladding. They possess remarkable load-bearing capacity, enabling the construction of substantial and robust structures. Furthermore, steel sheets offer fire resistance, thereby enhancing the safety of buildings. Additionally, they are resilient against pests, rot, and corrosion, ensuring a prolonged lifespan for constructions. Moreover, steel sheets can be effortlessly fabricated and tailored to meet diverse construction requirements, making them a cost-effective and efficient option. In summary, steel sheets are highly suitable for construction applications due to their strength, durability, versatility, and various other advantageous properties.

- Q: Are steel sheets suitable for roofing?

- Indeed, steel sheets make an ideal roofing material. Steel, being both sturdy and durable, can endure even the harshest weather conditions, including heavy rainfall, snow, and strong winds. Moreover, it boasts fire resistance, pest resistance, and rot resistance, making it a trustworthy option for long-lasting roofing solutions. In addition to these advantages, steel sheets are lightweight and simple to install, leading to reduced labor and installation expenses. Furthermore, they are available in a wide range of colors and finishes, enabling customization to suit the aesthetic of any structure. All in all, steel sheets offer exceptional protection and durability, which explains their popularity in roofing applications.

- Q: Can steel sheets be used for manufacturing electrical enclosures?

- Indeed, it is possible to utilize steel sheets in the production of electrical enclosures. The durability, strength, and capability of steel to provide essential safeguarding for electrical components have rendered it a widely employed material for constructing such enclosures. By employing steel sheets, one can ensure that the enclosure possesses robustness and can endure diverse environmental conditions. Furthermore, steel possesses commendable electromagnetic shielding properties, which aid in safeguarding delicate electronic equipment against interference. Additionally, steel sheets are resistant to fire, rendering them appropriate for manufacturing enclosures that must adhere to safety regulations. In summary, steel sheets are a dependable option for fabricating electrical enclosures due to their attributes and appropriateness for the intended purpose.

Send your message to us

Color Corrugated Galvanized Steel Sheet corrugated color steel sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords