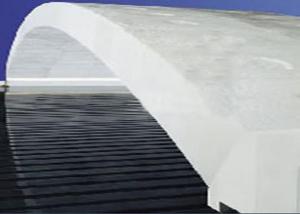

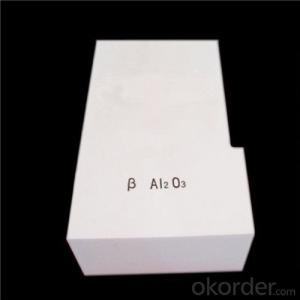

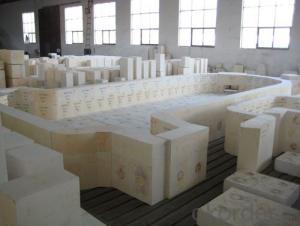

Fused Cast Alumina Crundum Brick for Glass Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Features of Fused Cast Alumina Crundum Brick For Glass Furnace

The typical glass contact materials for the end zones of furnaces when glass quality is the priority : TV Glass, high quality

| ||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||

| Physical and chemical index: | ||||||||||||||||||||||||||||||||||||||||||||||||

| ||||||||||||||||||||||||||||||||||||||||||||||||

- Q: You are making 10 tons of concrete that is 47.6% cement by mixing a 20% cement mixture with an 89% cement mixture.a) How much of the 89% cement mixture must you use?b) How much of the 20% cement mixture must you use?Answer in units of tons

- Let m represent the number of tons of the 20% cement mix Let n represent the number of tons of the 89% cement mix Total batch: m + n = 10 Cement amount: 0.20m + 0.89n = 10×0.476 Solve for m and n: m = 6 and n = 4 Check this result in the original equation(s), I did! The final batch should contain 6 tons of 20% cement mix with 4 tons of 89% cement mix to have 10 tons of the 47.6% cement mix. ------------------------------------- What other units are there?

- Q: if its some kind of glue, is it a really strong kind of glue?

- It's a really strong glue. It dries clear. If you want the cement to dry invisibly, coat the layer smoothly. It also has a strong smell.

- Q: How Fireproof Is Cement? I Tryed To Make A Mold For Metal Casting Out Of It, But It Fell To Pieces. Did I Make It Wrong, Or Is Cement No Good For 1100?C+ ??

- The only thing I know about this is that for metal casting you are supposed to cover a concrete floor with sand, so if molten metal spills onto the floor possibly remaining water in the floor won't make it break up/explode. So I guess concrete is no good or you have at least to heat it up so all water will have evaporated. For bronze casting one generally uses a plaster-silica sand mix (between 1:1 to 1:2). Other options are sand molds. You could google green sand mold and look what info you find on that. Green sand mold means that the sand is just held together by using water. Another option is a resin bonded sand mold. Yet another are ceramic shell molds, but they are much more bother to make, so I'd not recommend trying to set this up just for yourself. It depends what level of detail you need and what you want to cast. For jewelry style casting bought investment material are generally better, but uneconomical for anything larger.

- Q: Which type of cement

- portland cement, 3 parts gravel 2 parts sand 1 part cement just enough water to make a paste

- Q: I skateboard and snowboard, and falling on the cement, or falling in the snow doesn't hurt nearly as much as falling on strait ice, like in an ice-skating rink. Why is that?

- snow has a lot of air between the snow particles, so your fall is cushioned...(in physics terms, the time it takes the snow to bring your speed to zero is longer therefore it requires less force) however, I am not sure about ice vs. cement...cement hurts pretty badly...maybe you are feeling the effects of the cold? not really sure how to explain your experiences on ice, but falling on cement is something I would definitely try to avoid

- Q: As there are many types of cement, i want basic types of cement

- Type 1 - Normal portland cement. Type 1 is a general use cement. Type 2 - Is used for structures in water or soil containing moderate amounts of sulfate, or when heat build-up is a concern. Type 3 - High early strength. Used when high strength are desired at very early periods. Type 4 - Low heat portland cement. Used where the amount and rate of heat generation must be kept to a minimum. Type 5 - Sulfate resistant portland cement. Used where the water or soil is high in alkali.

- Q: I spray painted a lamp in my garage and now i have a circle on the cement. How do i get it off with out using one of those power spayers?

- sand blasting will do the trick - all else, there are chemicals that can be purchased @ lowe's , home depot etc under graffitii removal.. that will work - i would try these places -

- Q: How come i can kickflip on grass but not on cement?

- The grass keeps the board from moving because the wheels are stuck in the grass because the grass gets stuck under the wheel causing it not to move.On cement the board moves and it is harder to do when the board moves.

- Q: what is the volume of 1 bag of cement?

- Are you really asking how much concrete will one bag of concrete mix will make? Cement is a component of concrete, along with sand, aggregate and water. Cement on its own is useless without the other components. Cement is the glue and without anything to glue together, you really have nothing but dried glue. Cement usually comes in 50 lb bags. Concrete comes in 40 lb, 60 lb 80 lb bags. 40 lb bags of concrete makes just under 1/3 cu ft of concrete 60 lb bags of concrete makes just under 1/2 cu ft of concrete. 80 lb bags of concrete makes just under 2/3 cu ft of concrete

- Q: My brother was called for an interview as accountant ,, is it a good employer which pay well ??

- The best company in this field is a french company called Lafarge established 1833 largest by mass of production shipped abroad ironically ..... its first international contract was for the delivery of 110,000 tonnes of lime was directed to the Suez Canal construction project in Egypt ( we da yedeena fekra add eah el Balad dy kan masekhaa 7ad byef-ham awee zamaan ! ) aside to the fact that It was the first company to research and develop calcium aluminate cements. It was also one of the first companies to produce white Portland cement how ever Titan is considered to be No. 8 ( very good rank) ya3ny sherka mo7tarama awee khaly akhook yakhod feeha 2: 5 seneen khebra we yeb3at cv.s to lafarge they would certainly like to hire an Egyptian if he is qualified for the job how do i know ? >>>>> there history say so !

1. Manufacturer Overview

| Location | Henan,China (Mainland) |

| Year Established | 2007 |

| Annual Output Value | US$2.5 Million - US$5 Million |

| Main Markets | North America; South America; Eastern Europe; Southeast Asia; Africa; Oceania; Mid East; Eastern Asia; Western Europe; Central America; Northern Europe; Southern Europe |

| Company Certifications | business license |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai,Qingdao,Tianjin |

| Export Percentage | 51% - 60% |

| No.of Employees in Trade Department | 6-10 People |

| Language Spoken: | English, Chinese, Spanish, Japanese, Portuguese, German, Arabic, French, Russian, Korean, Hindi, Italian |

| b) Factory Information | |

| Factory Size: | 10,000-30,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered Design Service Offered |

| Product Price Range | High and/or Average |

Send your message to us

Fused Cast Alumina Crundum Brick for Glass Furnace

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 8 Tons m.t.

- Supply Capability:

- 1000 Tons per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords