Fused Cast Zirconia Alumina Brick for Glass Furnace / AZS Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

What is Fused Cast Brick AZS?

l AZS Bricks, Alumina-Zirconia-Silica (AZS) refractories are mainly used for melting glass furnaces, can stand aggressive conditions in contact with molten glass.

l We offer complete Glass Furnace Refractories - AZS Bricks, Oxidized Fused Cast AZS Brick, AZS Mortars, Castables at the most competitive prices, and we offer technical supports such as glass furnace design and installation per your request.

l We can produce AZS brick according to your specification or requirements. Detailed AZS bricks technical data sheet are avalible upon request.

l For glass industry projects like Glass Furnace Hot and Cold Repair, Glass Furnace Demolition, Glass Furnace Reconstruction, we are here to help you.

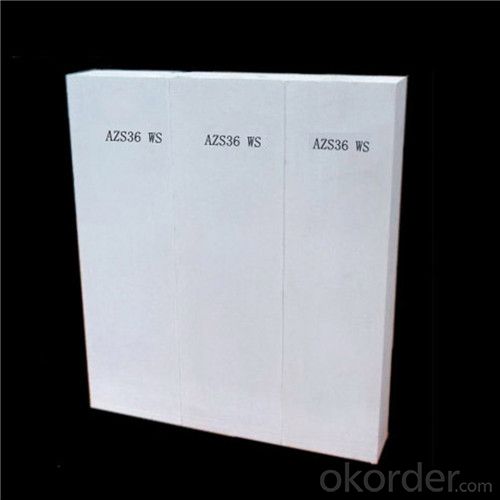

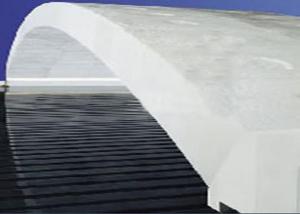

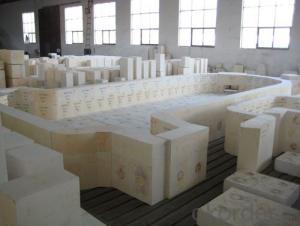

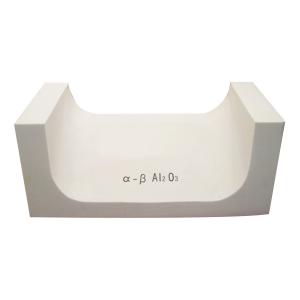

Image of Fused Cast Brick AZS

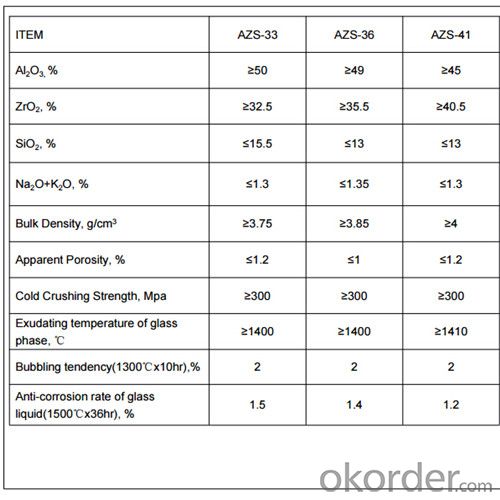

Technical Data of Fused Cast Brick AZS

Why Choose Us

l We are a government owned company with ISO certificate.

l We are listed in Global Fortune 500 with D & B report.

l We have more than 11 refractory production facilities and bases across China. We have a wide products range, such as ceramic fiber products (ceramic fiber blanket, module, board, paper, bulk), ceramic fiber textile (ceramic fiber rope, cloth, tape, yarn) etc, refractory brick (fireclay brick, high alumina brick, silica brick, magnesia brick etc), monolithic refractory materials, insulating fire brick, calcium silicate board, mica sheet, steel fiber. You can find various products here, and we can combine the light weight ceramic fiber products with the heavy weight refractory brick in one container delivery, then save the sea freight for you.

l We have strict materials selecting system and quality control system. We have the ability to take responsibility for your orders and product quality.

FAQ

Q1: How do you control the products quality?

A1: With strict quality control system throughout the materials selection and production process, our refractory and ceramic fiber products quality is effectively controlled to meet customer requirements. From the raw materials selecting, our quality control begin. The quality certificates of raw materials are required and each batch will be tested before using. During production, the quality control is conducted by workers and then each piece will be sorted and examined by quality supervisor.

Q2: What`s the lead time for my order?

A2: It depends on customers’ requirements and our production schedule. And usually we need 30-60 days for refractory bricks, 10-25 days for unshaped refractory materials and 10-20 days for ceramic fiber blankets.

Q3: Can you offer Door-to-Door delivery?

A3: Yes, but only for some countries such as U.S., UAE, Saudi Arabia, Iran, and Russia, etc.

Q4: What is the minimum quantity?

A4: There is no minimum order quantity. Depending on the item and processing, there may be a minimum production required, however we can offer a quotation based only on the quantity you need.

Q5: Can you give me a brief introduction of the application of your products?

A5: CNBM (China National Building Material) core refractory business comprises the production, sale and installation of high-grade refractory products, the development and implementation of customized system solutions as well as rendering outstanding services for the key industries in Glass, Iron& Steel, Petrochemical, Cement, Ceramic and Nonferrous Metals.

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

- Fused zirconia corundum brick is also called AZS AZS English is abbreviated to AZS, is based on three chemical composition of Al2O3 - Zr02 - Sio2 phase diagram of three component system, according to the content of the order, Al2O3 A, Zr02 Z, Sio2 S, national standards for the use of this abbreviation, such as No. 33 cast brick, abbreviated as AZS, 33#, No. 36 fused zirconium corundum brick, abbreviated as AZS, 36#, No. 41 fused zirconium corundum brick, abbreviated as AZS - 41#.

- Q: What are the categories of bricks?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: Just what is in the furnace material?

- It can be used as high temperature building materials and structural materials for construction kilns and various thermal equipments, and can undergo various physical, chemical and mechanical changes at high temperature. For example, refractory clay brick, high alumina brick, brick, brick etc..

- Q: What are ordinary bricks, refractory bricks, hollow bricks?

- Material. Light yellow or brownish. The utility model is mainly used for laying smelting furnaces, and can withstand high temperature between 1580 DEG C and 1770 DEG C. Also called brick. Refractory material of a certain shape and size.

- Q: What are kiln bricks?

- Kiln brick masonry brick kiln used brick, brick is a brick kiln.

- Q: What are the specifications for bricks?

- Thecompressive node as a new type of building energy-saving wall materials, which can be used for masonry walls, but also has good thermal properties, in line with the construction of the building module, reduce the loss in the process of construction, improve work efficiency; the hole rate reached more than 35%, can reduce the weight of the wall, save the foundation engineering cost. Compared with common sintered porous brick, it has the characteristics of heat preservation, heat insulation, light weight, high strength and high construction efficiency. The product is made of shale as raw material. It is produced by high vacuum extrusion molding machine and one yard firing process

- Q: Is the wall around the fire area using a firewall? What's the difference between a fireproof brick and a regular brick?

- Fire bricks burn well!!In fact, the firewall does not necessarily have to use the so-called "fire brick", but to see the brick fire limit!240, the fire limit seems to be 4 hours, 370 I do not remember clearly, fire codes have, you see, do not think so naive!

- Q: Outside wall tile (whole body smooth surface has small hole split brick) has cement pollution, with what product cleaning (cement, mortar, cleaning agent)?

- Ordinary brick size of 240 mm * 115 mm * 53 mm, according to compressive strength (Newton / square millimeter, N / mm2) size is divided into MU30, MU25, MU20, MU15, MU10, MU7.5, these intensity levels. Clay brick materials, cheap, durable, and fire prevention, heat insulation, sound insulation, moisture absorption and other advantages, is widely used in civil engineering. Waste brick can also be used as aggregate of concrete. In order to improve the shortcomings of ordinary clay bricks, such as small, self important and waste of soil, they are developing in the direction of light weight, high strength, hollow and big blocks.

- Q: What material is good for refractory bricks?

- According to the composition of refractory bricks, they can be divided into five major categories, namely, silicon aluminum refractory bricks, basic series refractory bricks, carbon containing refractory bricks, zirconium containing refractory bricks and insulating refractory bricks.

- Q: What's the use of refractory bricks?

- Refractory brick fire resistance is greater than 1580 degrees, and the average brick three or four Baidu softened deformation. The refractory brick because of its high refractoriness, and high pressure molding, and after high temperature kiln, so the use of strength is particularly good, practicality is particularly strong in high temperature liquid, gas with high temperature, high temperature solid, chemical corrosion products etc..

Send your message to us

Fused Cast Zirconia Alumina Brick for Glass Furnace / AZS Brick

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches