Corundum Brick - Fused Cast AZS Brick for Glass Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

In order to catch the rapid increasing demand of grinding media and provide full series to customers,we have developed grinding media with 92% AI2O3,75% AI2O3 AND 65% AI2O3.The technical data of each series is listed as following table.

With overwhelming merits in higher density,more regular shape,easily classifying and assorting,superior grinding efficiencies and competitive price prior to natural cobble stones and conventional grinding media,our Alumina Grinding Media are excellent for grinding processing of ceramic bodies and glaze materials in tile industries and surface polishing of the ceramic bearing applicant.

Specifications

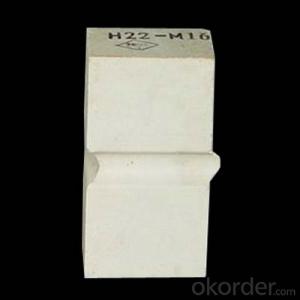

1. Low thermal conductivity

2. High strength and resistance to corrosion

3. Low heat capacity

4. Low content of impurities

5. High insulation

6. Excellent thermal shock resistance

7. Low density

Features

1.High density

2.Strong corrosion resistance

3.Good slag resistance

4.Low permannent liner change on reheating

Application

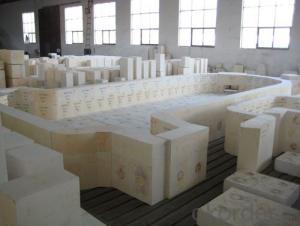

Corundum brick primarily used for the key parts of the industrial furnace of steel,metallurgica,electronics,petrochemical,chemical fertilizers,non-ferrous metals,refractorty material etc high temperature industrial kiln furnace,such as glass furnace,cement kiln, heaters molten steel ladle,metallurgical furnaces for nonferrous metals and furnaces for chemical engineering industries.

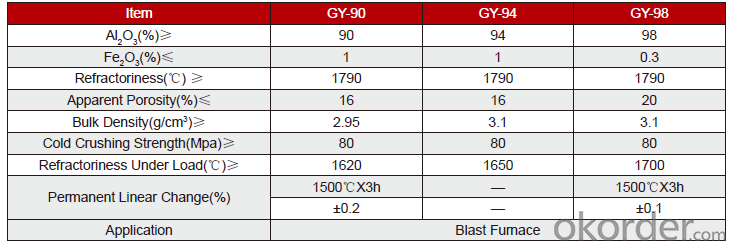

Physical properties and chemical composition

FAQs

Q1 What’s the transport method?

A1 FCL delivery goods with wooden pallet or wooden case by sea; If LCL delivery, must with wooden case; Sometimes need open top, flat rack or bulk cargo.

Q2 What’s the required payment term?

A2 Generally 30% TT as the prepayment, 70% TT before delivery. If need, 100% Irrevocable Letter of Credit or negotiation.

Q3 Which country are our products exported to?

A3 Apart from entire Chinese market, the US, Russia, Japan, Korea, Australia and some Southeast Asian Nations.

- Q: What kind of fused corundum corundum brick should be used for each part of the glass furnace?

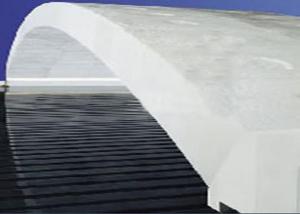

- The compact microstructure of AZS33# zirconia corundum brick makes the bricks resistant to glass liquid corrosion, and it is difficult to produce stone or other defects in the glass kiln. It is the most widely used product in the glass furnace. It is mainly applied to the upper structure of the melting pool, the wall brick of the working pool and the paving brick, the material way, etc..

- Q: Zirconium corundum 25 content and 40 content, how to distinguish in appearance?

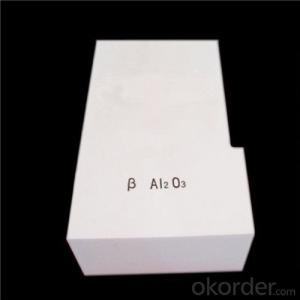

- The fused zirconia corundum brick is mainly made of fused zirconia and corundum. ZrO2-Al2O3-SiO2 three element system fused brick, containing Al2O3:40% to 50%, ZrO2:30% to 50%, SiO2:10% to 17%.From the point of view of data analysis, there is no radioactive substance in it, and it will not cause harm to the human body.

- Q: What material is used in an iron smelting furnace?

- In fact, refractory refractory ah is special ceramic frequently used AZS brick, corundum brick, magnesia chrome brick, silicon carbide, silicon nitride bonded silicon carbide, nitrides, silicides, sulfide, boride, carbide and other non oxide refractory materials; calcium oxide, chromium oxide, alumina, Magnesium Oxide, beryllium and other refractory materials.

- Q: What does refractory consist of?

- Refractory materials can be divided into main raw materials and auxiliary raw materials according to their function in the production process of refractory materials.The main raw material is the main body of refractory. Auxiliary raw materials can be divided into binders and additives. The role of bonding agent is to make the refractory body in the production and use process has enough strength. There are commonly used lignin, phenolic resin, asphalt, cement, water glass, phosphoric acid and phosphate, sulfate, some main raw material itself has the effect of binder, such as clay; additive is to improve the production of refractory materials and construction technology, or strengthen the refractory material of some properties, such as stabilizer, water reducing agent, inhibitor, plasticizer, foaming agent, dispersing agent, bulking agent, antioxidant.

- Q: What is the blast furnace ceramic cup called by the refractory factory?

- The refractory bricks, which are suitable for blast furnace conditions, are vitrified by high temperature sintering. They are like a huge cup, so they are called ceramic cups. The name was taken by the French, and the technology was handed down from france!

- Q: What is the hardness of corundum refractory bricks?

- Such as zirconium corundum refractory brick, chrome corundum refractory titanium corundum refractory brick.

- Q: What's the size of the fused zirconia corundum refractories for glass furnace? What are the main kilns? How much is the dosage?

- Fused zirconia corundum refractory material of glass fiber kiln quantity is little, generally used in the kiln feed arch furnace flue, where large amount of places are currently using dense zirconium Zr, dense chromium

- Q: How do corundum bricks bind?

- Each refractory brick is provided with corresponding refractory mud, and corundum bricks are bonded with corundum mud.

- Q: What are the refractory materials?

- Neutral refractory is mainly composed of alumina, chromium oxide or carbon. Corundum products containing more than 95% of alumina are a kind of high quality refractory materials with a wide range of uses. Chrome brick by using chromium oxide as the main component of the corrosion resistance of steel slag is good, but the poor heat shock resistance, high load low deformation temperature. Carbon refractories with carbon bricks, graphite and silicon carbide products, low coefficient of thermal expansion, high thermal conductivity, heat vibration performance, high strength, corrosion resistance to acid and salt, without wetting of the metal and slag, light. It is widely used as lining material of high temperature, and also used as lining of autoclave in petroleum and chemical industry.

- Q: What kind of rock is corundum produced?

- If Ti4+ and Fe2+ containing a small amount of blue, a sapphire; containing six symmetrically distributed acicular rutile or other inclusions in some crystals, can produce six star awn, known as star ruby or sapphire stars, are precious stones. Corundum is vitreous luster with no cleavage, but cracks occur because of the presence of poly twin crystals that are often formed by the base or face of a face. Specific gravity 3.98. Of relatively low silicate igneous and metamorphic rocks and common in alluvial deposits. The U.S. state of North Carolina and Georgia, Russia's Ural mountains, South Africa as the main origin of the transvaal.

Send your message to us

Corundum Brick - Fused Cast AZS Brick for Glass Furnace

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords