High Alumina Corundum Brick for Kiln Furnace and Glass Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

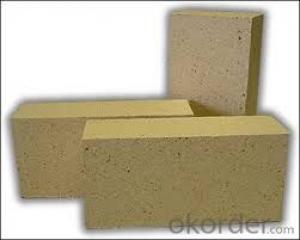

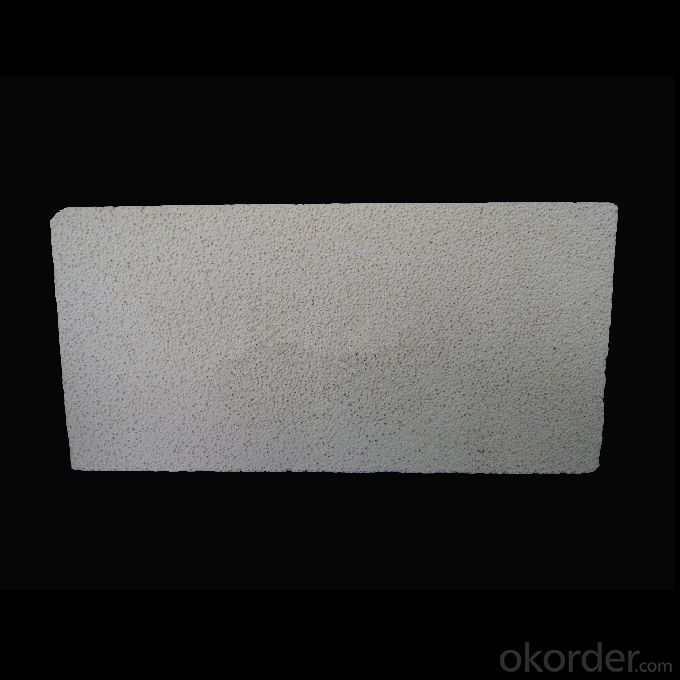

Description of Corundum Brick

Corundum Brick for Kiln Furnace Glass Furnace are used as the main raw material alumina hollow ball, high performance Micropowder for additives, organic material temporary binder high temperature shuttle kiln baked.

Corundum Brick can greatly improve the thermal efficiency of the kiln to shorten the production cycle, reduce the kiln body weight to achieve energy saving.

Features of Corundum Brick

containing a large number of closed pores

have a lightweight high temperature

good insulation properties

refiring small contraction

excellent thermal shock resistance

strong resistance to the corrosive gas and slag.

Specifications for Corundum Brick

Corundum Brick for Kiln Furnace Glass Furnace | |

Item | Standard |

AI2O3(%) | 30 |

Fe2O3 (%) | 3 |

Refractoriness (SK) | 32 |

Refractoriness under load, 0.2MPa, Ta, ((°C) | 1300 |

Porosity (%) | 22-26 |

Bulk density (g/cm³) | 2.05 |

Cold crushing strength (MPa) | 25 |

Thermal expansion at 1000°C (%) | 0.6 |

Fire clay brick SK-34 | |

Item | Standard |

AI2O3(%) | 38 |

Fe2O3 (%) | 2.5 |

Refractoriness (SK) | 34 |

Refractoriness under load, 0.2MPa, Ta, ((°C) | 1350 |

Porosity (% | 19-23 |

Bulk density (g/cm³) | 2.10-2.15 |

Cold crushing strength (MPa) | 25 |

Thermal expansion at 1000°C (%) | 0.6 |

Fire clay brick SK-36 | |

Item | Standard |

AI2O3(%) | 50 |

Fe2O3 (%) | 2 |

Refractoriness (SK) | 36 |

Refractoriness under load, 0.2MPa, Ta, ((°C) | 1450 |

Porosity (% | 20-24 |

Bulk density (g/cm³) | 2.30-2.40 |

Cold crushing strength (MPa) | 45 |

Thermal expansion at 1000°C (%) | 0.

|

Images of Corundum Brick

Typical Application of Corundum Brick

Corundum Brick can be in direct contact with the flame, to apply to the cracking furnace, hot stove, furnace, tunnel kiln, push board kiln, crucible furnace and electric furnace, electric kilns lined widely used in metallurgy, refractories, light industry, chemical industry, ceramics, glass, electronics and other industries. Dimensions of the Corundum Brick, the physical and chemical indicators, service life have reached or exceeded the level of similar products at home and abroad.

FAQ of Corundum Brick

1. Does your factory have any certifications?

2. Can we accept OEM ?

YES! We can according your demand to produce.

3. Can we accept the detective of the third-party verification company ?

YES! We can accept the detective from any third-party verification company including the SGS, BV and so on.

4.How about the delivery?

The company provides just-in-time delivery with its streamlined supply chain.

5.Why we attend customers queries promptly?

We believe that if customers are satisfied then it proves our worth well.Customers are always given quick support.

- Q: What are the main components of high alumina bricks?

- Sweat is like water mineral alumina bauxite, aluminum ore, magnesite, waves of gibbsite. Anhydrous alumina raw material, such as corundum, alumina, fused corundum. High alumina brick Zhengzhou gold company specializing in the production of various specifications, you can directly ask their technical staff.

- Q: What are the grades of high alumina bricks?

- High alumina brick according to the aluminum content is generally divided into: super high alumina brick, a high aluminum brick, two high alumina brick, three high alumina brick

- Q: Can high alumina brick resist carburizing?

- The resistance to carburization is not directly related to the bulk density of bricks

- Q: What are the characteristics of high alumina bricks?

- A neutral refractory with an alumina content of more than 48%. Made from alumina or other raw materials of high alumina content; formed and calcined.

- Q: Refractory brick, high alumina brick, magnesia chrome brick, magnesia brick, clay brick, which type of high temperature refractory brick?

- The super high alumina brick in high alumina refractory brick has the highest refractoriness, and the corresponding production cost is higher.

- Q: How are the grades of high alumina bricks differentiated?

- In China, the content of Al2O3 in high alumina brick is usually divided into three categories: I, etc. - Al2O3 content > 75%; II, etc. - Al2O3 content is 60 to 75%; III and so on - Al2O3 content is 48 ~ 60%.

- Q: How to reduce the harm caused by two times mullite in high alumina refractory material

- Prolong the sintering time and adjust the aluminum content of the high alumina brick.

- Q: The difference between clay bricks and clay bricks

- Sintering bricks do not have clay bricks, so sintering bricks are made of stone. Clay brick is clay cooking, two yo, qualitative difference, but the appearance and color almost, but the quality is very different, life expectancy is also a great gap.

- Q: What should be used as binder for making high alumina bricks?

- Bond for making high alumina brick: soft clay has good plasticity, so the high alumina brick is usually made of soft clay as bond. However, the free Al2O3 free SiO2 and bauxite clinker clay in under 1200 degrees occurred two times of Mullization reaction, generate large volume expansion, silicon porosity, strength reduction. Therefore, the amount of clay powder in the ingredient should be no more than 5%.

- Q: High alumina brick 80 with which high aluminum cement?

- In order to maintain a reasonable comprehensive lining, should adopt high quality aluminum refractory mud, such as Sichuan resistance card phosphate refractory mud, refractory clay, high alumina refractory mud PA-80 LN-75, if you use the card volume of Sichuan resistant refractory clay masonry, the effect is better.

Send your message to us

High Alumina Corundum Brick for Kiln Furnace and Glass Furnace

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords