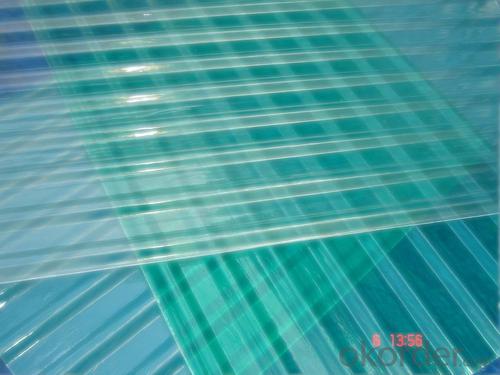

FRP Roofing Panel - Fiberglass Roofing Sheets / Corrugated Plane Skylight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP plane skylightusually use a protecting facility in construction site,steel structured workshop and warehouse,canopy,packingsheds,corridors,studio light awning and greenhouse etc as the excellent light transmittance.

FRP plane skylightis the more strengthened, safety, and more econimal greenhouse panel with the properties of waterproof,good light transmittance,heat insulation,strong impact resistant,withstand extreme temperature.

Normal thinkness:1.2mm,1.5mm,2.0mm

FEATURES

1) The fiberglass content about 27%-30%.

2) Weather resistant and Self-clean ability

3) Excellent yellowness resistance

4) Strong impact resistant and low bending rate

5) Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

SPECIFICATIONS

Thickness | Mesh size | Panel size | Open area | Weight |

(MM) | (MM) | (MM) | % | (kg/m2) |

25 | 38*38 | 1220*3660 | 68 | 12.5 |

1220*4076 | ||||

1220*4000 | ||||

30 | 38*38 | 1220*3660 | 68 | 14.75 |

1220*4000 | ||||

38 | 38*38 | 1007*4047 | 68 | 19.5 |

1220*3660 | ||||

1220*4000 | ||||

50.7 | 50.7*50.7 | 1220*3660 | 71 | 23.5 |

1220*4000 | ||||

30 | 19*19 | 1007*4007 | 40 | 18.1 |

38 | 19*19 | 1007*4007 | 40 | 23.5 |

PICTURES

- Q: Can FRP roofing panels be used in sloped roofs?

- Certainly, sloped roofs can incorporate FRP (Fiberglass Reinforced Plastic) roofing panels. These lightweight, durable, and weather-resistant panels are versatile for various roofing applications. They offer an economical and enduring roofing solution for flat and sloped roofs alike. Nevertheless, it is crucial to consider the incline of the roof when choosing and installing FRP panels. Steeper slopes may warrant additional precautions, such as utilizing sturdier fasteners or incorporating anti-slip coatings, to ensure proper installation and prevent water accumulation. Therefore, it is advisable to consult a roofing professional to assess the suitability and specific requirements of implementing FRP panels on a sloped roof.

- Q: Can FRP roofing panels be used in wastewater treatment plants?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in wastewater treatment plants. FRP panels are known for their excellent corrosion resistance, durability, and low maintenance requirements, making them a suitable choice for such harsh environments. Additionally, FRP panels are lightweight, easy to install, and can be customized to fit specific project requirements. They also provide superior resistance to chemicals, UV rays, and weathering, ensuring long-term performance and cost-effectiveness. Overall, FRP roofing panels are a reliable option for wastewater treatment plants due to their ability to withstand corrosive conditions while providing a strong and durable roofing solution.

- Q: Can FRP roofing panels be used for outdoor structures?

- Outdoor structures can indeed utilize FRP (Fiber Reinforced Plastic) roofing panels. Renowned for their sturdiness, robustness, and ability to withstand diverse weather elements like UV rays, rain, and wind, FRP roofing panels are specifically engineered to endure challenging outdoor conditions, ensuring exceptional safeguarding for various structures. They are frequently employed in outdoor settings, including patios, pergolas, carports, sheds, and agricultural buildings. Apart from their exceptional resistance to weather, FRP roofing panels possess the advantages of being lightweight, easy to install, and having a long lifespan. All in all, FRP roofing panels present a dependable and pragmatic choice for outdoor structures.

- Q: Are FRP roofing panels suitable for parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are suitable for parking structures. FRP roofing panels are known for their durability, lightweight nature, and resistance to corrosion, making them an excellent choice for parking structures. These panels are designed to withstand harsh weather conditions, including heavy rain, snow, and hail, while providing a long-lasting and low-maintenance roofing solution. Moreover, FRP roofing panels offer excellent UV resistance, preventing color fading or degradation over time. This is particularly important in parking structures, where vehicles are often exposed to direct sunlight for extended periods. The UV resistance of FRP panels ensures that the roofing remains aesthetically pleasing and does not require frequent painting or touch-ups. Additionally, FRP roofing panels can be installed quickly and easily due to their lightweight nature. This reduces the construction time and cost associated with parking structure projects. Furthermore, the lightweight feature of FRP panels puts less stress on the building's structure, making them an ideal choice for retrofitting existing parking structures. Another advantage of FRP roofing panels is their ability to be customized to suit specific design requirements. These panels can be manufactured in various profiles, colors, and thicknesses, allowing architects and builders to achieve the desired aesthetic while maintaining functionality and performance. In conclusion, FRP roofing panels are a suitable choice for parking structures due to their durability, lightweight nature, resistance to corrosion, UV resistance, ease of installation, and customization options. These panels provide a long-lasting and low-maintenance roofing solution that can withstand harsh weather conditions, making them an ideal choice for parking structures of all sizes.

- Q: Can FRP roofing panels be used for outdoor storage sheds or workshops?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can certainly be used for outdoor storage sheds or workshops. FRP panels are known for their durability, strength, and resistance to various weather conditions, making them an excellent choice for exterior applications. These panels are lightweight, making them easy to handle and install. They are also resistant to corrosion and UV rays, which ensures they will withstand the harsh outdoor elements without deteriorating or losing their aesthetic appeal over time. In addition, FRP roofing panels offer excellent insulation properties, which can be beneficial for sheds or workshops that require a controlled environment. They can help maintain a stable temperature inside the building, reducing the need for additional heating or cooling systems. Furthermore, FRP panels are available in various colors and designs, allowing you to choose a style that suits your preferences and complements the overall aesthetics of your outdoor space. Overall, due to their strength, durability, weather resistance, insulation properties, and aesthetic options, FRP roofing panels are a suitable choice for outdoor storage sheds or workshops. They provide a long-lasting and reliable roofing solution that can withstand the demands of outdoor environments.

- Q: Can FRP roofing panels be used for covered parking structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used for covered parking structures. FRP panels are lightweight, durable, and have excellent resistance to corrosion, making them an ideal choice for outdoor structures such as parking covers. They are also UV resistant, allowing them to withstand harsh weather conditions and prolonged exposure to sunlight without deteriorating. Additionally, FRP panels can be easily installed and require minimal maintenance, making them a cost-effective solution for covered parking structures.

- Q: Can FRP roofing panels be used for both residential and commercial greenhouses?

- Yes, FRP roofing panels can be used for both residential and commercial greenhouses. FRP (Fiberglass Reinforced Plastic) panels are known for their durability, excellent light transmission, and resistance to weathering, making them suitable for greenhouse applications in both settings.

- Q: Are FRP roofing panels easy to clean?

- Yes, FRP roofing panels are easy to clean. They have a smooth surface that can be easily wiped or rinsed off to remove any dirt or debris. Additionally, their durable and non-porous material makes them resistant to stains, allowing for hassle-free maintenance.

- Q: Do FRP roofing panels require any special ventilation or air circulation?

- Special ventilation or air circulation is necessary for FRP roofing panels to ensure their longevity and prevent potential issues. The extent of the ventilation requirements may vary depending on the specific application and environment. FRP panels can withstand various temperatures and weather conditions, but proper ventilation is crucial. The main purpose of ventilation is to prevent the accumulation of heat and moisture beneath the roofing panels. Insufficient ventilation can lead to thermal expansion and damage to the panels. It can also cause condensation, which may result in corrosion or the growth of mold and mildew. To achieve proper ventilation, it is recommended to install a ventilation system that allows air to circulate beneath the roofing panels. This can be accomplished through ridge vents, soffit vents, or other types of ventilation systems that provide intake and exhaust airflow. The design and size of the ventilation system will depend on factors such as roof size, climate, and local building codes. Consulting the manufacturer's guidelines and recommendations for the specific FRP roofing panels is important as they may have specific ventilation requirements. It is also advisable to work with a professional roofing contractor who can assess your project's needs and ensure proper ventilation. In conclusion, special ventilation or air circulation is necessary for FRP roofing panels to prevent heat buildup and moisture condensation. Adequate ventilation is essential for maintaining the panels' integrity, longevity, and a healthy environment beneath the roof.

- Q: Can FRP roofing panels withstand high winds?

- Yes, FRP roofing panels are designed to withstand high winds. They are made from a durable and strong material that can resist the force of strong winds, making them a reliable choice for areas prone to high wind conditions.

Send your message to us

FRP Roofing Panel - Fiberglass Roofing Sheets / Corrugated Plane Skylight with High Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m

- Supply Capability:

- 30000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords