Frp Roof Panels - Corrosion Resistance FRP Roofing Tile Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

PRODUCT DESCRIPTION

FRP GRP Fiberglass Glassfiber Corrugated Roofing is a patent of our company, not like other FRP products, it is produced without yarn, instead, we use mat only. Therefore, the corrugated sheet is more strong in both horizontal and vertical direction.

Fiberglass corrugated sheet is usually used in construction site as protecting facility. It is dagarous for workers in building site since you never know if there is something hard drop down from the high area. So corrugated sheet is installed for preventing the stuff dropping down to hurt people.

Besides, it could also applied as the roof of the constructions

FEATURES

1) The fiberglass content of new generation greenhouse panel has been improved by 18.3%.

2) Weather resistant and Self-clean ability.

3) Excellent yellowness resistance.

4) Strong impact resistant and low bending rate.

5)Withstand extreme temperature from -38 degree to +110 degree for a long time

6) Aging resistant: specified F4 film added on surface and gel coat makes it endurable for long.

7) More strengthened, safer, cleaner and more economical greenhouse panel.

8) Mainly serve the big factory, warehouse, super markets and other steel-structured project.

SPECIFICATION

Name | FRP Roofing |

Material | Fiberglass |

Width | 880mm/1050mm |

Effective width | 800mm/960mm |

Wave length | 160mm |

Wave height | 30mm |

Pitch | 220mm |

Thickness | 3/2.5mm |

Length | Customized but must be a multiple of wave pitch |

Color | Purplish Red, Brick Red, Grey, Green, Blue or customized |

Application | House, villa, pavilions, industrial plants, large warehouses, supermarkets, stadiums etc |

MOQ | 1000 Square meter |

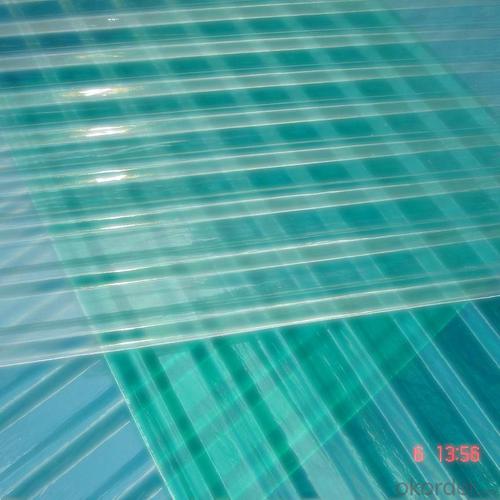

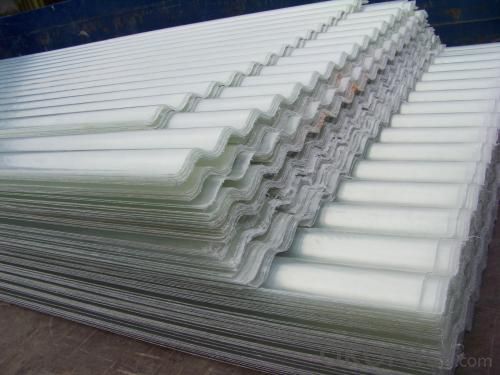

PICTURES

- Q: Can FRP roofing panels be installed on sloped roofs without leaking?

- Correct installation techniques are essential for preventing leaks when installing FRP roofing panels on sloped roofs. FRP panels, known for their weather resistance and durability, are a suitable choice for sloped roofs. However, it is crucial to follow proper installation procedures. To install FRP roofing panels on sloped roofs without leaks, the following steps should be followed: 1. Prepare the roof surface: Make sure the roof surface is clean, devoid of debris, and in good condition. Any existing leaks or damages should be fixed before installing the FRP panels. 2. Apply underlayment: Use an appropriate underlayment, such as a waterproofing membrane, to create a barrier between the roof and the FRP panels. This will prevent water penetration and potential leaks. 3. Overlap panel installation: During panel installation, ensure that each panel overlaps correctly. This will create a waterproof seal between the panels, minimizing the risk of leaks. Refer to the manufacturer's instructions for specific overlap requirements. 4. Seal joints and fasteners: Give careful attention to the joints between panels and the fasteners used to secure them. Apply a high-quality sealant to seal these areas effectively, ensuring they are watertight. This will further reduce the chances of leaks. 5. Proper flashing installation: Install flashing around roof penetrations, like chimneys or skylights, to prevent water from entering these vulnerable areas. Correctly install flashings and seal them with suitable sealants. 6. Regular maintenance: Regular maintenance is vital to ensure long-term performance and prevent potential leaks. Periodically inspect the FRP roofing panels for any signs of damage or deterioration. Promptly replace any damaged panels or sealants to maintain the roof's integrity. By adhering to these steps and following proper installation techniques, FRP roofing panels can be installed on sloped roofs without significant leak risks. It is advisable to consult with a professional contractor or manufacturer for specific guidance and to comply with local building codes and regulations.

- Q: Can FRP roofing panels be painted or coated with a protective finish?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be painted or coated with a protective finish. The smooth surface of FRP panels allows for easy application of paint or coatings. However, it is important to select the appropriate type of paint or coating that is compatible with the FRP material. Acrylic or latex-based paints are generally recommended for FRP panels as they adhere well and provide good durability. Before applying any paint or coating, it is crucial to properly clean and prepare the surface by removing any dirt, dust, or grease. Additionally, it is advisable to consult the manufacturer's guidelines or seek professional advice to ensure the best results and maintain the structural integrity of the FRP roofing panels.

- Q: Can FRP roofing panels be installed on steel structures?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be installed on steel structures. FRP panels are a versatile roofing material that can be used on various types of structures, including steel buildings. The lightweight nature of FRP panels makes them suitable for installation on steel structures without adding excessive weight to the overall structure. Additionally, FRP panels provide excellent resistance to corrosion, which is beneficial when installing them on steel structures that are susceptible to rusting. Overall, FRP roofing panels can be a durable and cost-effective choice for steel structures.

- Q: Are FRP roofing panels resistant to graffiti or paint overspray?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally resistant to graffiti or paint overspray. The smooth surface of FRP panels makes it easier to remove graffiti or paint, and they can be cleaned using mild detergents without causing damage. However, it's important to note that certain types of graffiti or aggressive cleaning methods may require additional measures for complete removal.

- Q: Can FRP roofing panels be used in coastal areas with high salt exposure?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in coastal areas with high salt exposure. FRP panels are known for their durability, corrosion resistance, and ability to withstand harsh environments. They are specifically designed to withstand the effects of saltwater and salt air, making them suitable for coastal areas. However, regular maintenance and cleaning may be required to ensure the longevity of the panels in such conditions.

- Q: Can FRP roofing panels be used in areas with heavy snowfall?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in areas with heavy snowfall. FRP roofing panels are known for their durability and strength, making them suitable for withstanding heavy snow loads. However, it is important to consider a few factors when using FRP roofing panels in areas with heavy snowfall. Firstly, the pitch or slope of the roof should be taken into account. A steeper pitch allows snow to slide off more easily, reducing the risk of accumulation and potential damage to the roofing panels. Additionally, proper installation techniques should be followed to ensure that the panels are securely fastened and sealed to prevent any snow or water infiltration. It is also advisable to regularly remove accumulated snow from the roof to prevent excessive weight on the panels. This can be done using safe and appropriate snow removal techniques, such as using a roof rake or hiring professionals who are knowledgeable in snow removal. Lastly, it is essential to choose FRP roofing panels that are specifically designed and rated for heavy snow loads. These panels are typically reinforced and have higher load-bearing capacities, ensuring they can withstand the weight and stress caused by heavy snow accumulation. Overall, with proper installation, regular maintenance, and appropriate panel selection, FRP roofing panels can be effectively used in areas with heavy snowfall.

- Q: Installation points of glass fiber reinforced daylight tile

- Later, laid aside, plate location, construction by gradually to the direction of the roof eaves. The light plate is directly buckled on the side crest of the steel plate.? daylighting tile in front of the fixed pilot hole, the aperture must be greater than the diameter of the fixed screw 6-9mm, as the expansion and contraction.

- Q: Are FRP roofing panels suitable for green roof applications?

- Yes, FRP roofing panels are suitable for green roof applications. FRP panels provide excellent durability, weather resistance, and insulation properties, making them an ideal choice for green roofs. They can also be customized to accommodate drainage systems and support the weight of the vegetation. Additionally, FRP panels offer easy installation and low maintenance, making them a practical option for green roof projects.

- Q: Are FRP roofing panels suitable for bus shelters or transit stations?

- FRP roofing panels are the perfect fit for bus shelters or transit stations. Their durability, strength, and ability to withstand various weather conditions make them the ideal option for outdoor structures. To begin with, FRP panels possess exceptional resistance to UV radiation. This means they can endure prolonged exposure to sunlight without fading or deteriorating. This is especially vital for bus shelters or transit stations that are typically located outdoors and continuously exposed to sunlight. Furthermore, FRP panels have a high resistance to moisture and water damage. They don't absorb water, which prevents issues like rotting or warping that are common with other roofing materials. This is particularly beneficial for bus shelters or transit stations as they often encounter rain, snow, and other forms of precipitation. Additionally, FRP panels are lightweight yet sturdy, making installation easy while providing ample structural support. This is advantageous for bus shelters or transit stations as it reduces both installation time and costs. Moreover, FRP panels require little maintenance and are resistant to corrosion, making them a cost-effective choice for long-term use. They don't necessitate frequent painting or sealing, and their durability ensures they can withstand the wear and tear associated with high-foot traffic areas. In conclusion, FRP roofing panels are an outstanding choice for bus shelters or transit stations due to their durability, weather resistance, low maintenance demands, and cost-effectiveness.

- Q: Can FRP roofing panels be used in skylights?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels can be used in skylights. FRP panels are lightweight, durable, and resistant to UV rays, making them suitable for skylight applications. They provide excellent light transmission, insulation, and can be custom-made to fit various skylight sizes and shapes.

Send your message to us

Frp Roof Panels - Corrosion Resistance FRP Roofing Tile Balcony Roof Covering

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 300 m

- Supply Capability:

- 40000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords