FRP Roofing Panel - Fiber Reinforced Plastic Sheet Panel 0.5mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiber Reinforce Plastic Sheet Panel with 0.5 mm Thinkness

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1.light weight,high strength

2.excellent anti-corrosion performance

3.electric,heat and sound insulation

4.maintenance free

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

Easy to maintain.

High strength.

Long service life.

Easy to install.

Good light transmittance.

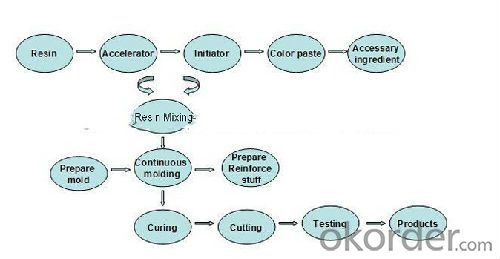

Production Process

Specification

Resin:Ortho Polyester (ORP), Iso polyester (ISO) , Vinyl ester (VE)

Size: Width Max. 3000 mm,Length customized

Thickness: 2-20mm

Surface: smooth with gel coat or not

Color: Green, yellow, grey, red, black, or any optional to you.

Chemical Resistance: VE > ISO > ORP

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Are FRP roofing panels resistant to impact from hail or falling tree branches?

- FRP roofing panels, also known as Fiberglass Reinforced Plastic panels, exhibit remarkable resistance to hail and falling tree branches. Their composition, which combines fiberglass and plastic resins, imparts exceptional strength and durability, resulting in their impressive impact resistance. Conventional roofing materials like asphalt shingles or metal sheets can suffer significant damage from hail. However, FRP roofing panels are explicitly engineered to endure such impacts. The robust fiberglass reinforcement effectively absorbs the force of hailstones, preventing them from penetrating the surface and causing leaks or other structural harm. Additionally, the plastic resins employed in the panels confer flexibility, further enhancing their ability to withstand hail impact. Similarly, falling tree branches pose a grave risk to roofing structures. Nevertheless, FRP roofing panels are renowned for their remarkable resistance to impact. They can bear the weight and force of tree branches without cracking or breaking, ensuring the building's protection even during storms or strong winds. Nevertheless, it is crucial to acknowledge that while FRP roofing panels are generally resilient against hail and falling tree branches, exceptionally severe weather conditions or extraordinarily large tree branches may potentially inflict some damage. Therefore, it is always advisable to evaluate the specific requirements of your location and consult with a professional roofing contractor to determine the most suitable roofing solution for your needs.

- Q: How do FRP roofing panels perform in extreme weather conditions?

- The exceptional performance of FRP (Fiberglass Reinforced Plastic) roofing panels in extreme weather conditions is well-known. These panels are specifically designed to endure harsh elements like heavy rain, strong winds, hailstorms, and even extreme temperatures. One of the main benefits of FRP roofing panels lies in their remarkable durability. The inclusion of fiberglass reinforcement provides them with added strength, making them resistant to cracking, chipping, and warping. As a result, these panels can withstand the impact of hailstones or falling debris during severe weather events. Moreover, FRP roofing panels exhibit a high level of resistance to water damage. They possess excellent water impermeability, which prevents water from seeping through and causing leaks. This characteristic is particularly crucial in areas that experience heavy rainfall or hurricanes. Additionally, FRP panels are engineered to resist UV degradation. They are manufactured with UV inhibitors that shield the material from the sun's harmful rays, thus preventing fading, discoloration, and deterioration over time. Therefore, even in regions with scorching heat or intense sunlight, FRP roofing panels will retain their strength and integrity. When it comes to wind resistance, FRP roofing panels are highly reliable. Their lightweight construction, in combination with the fiberglass reinforcement, enables them to withstand powerful winds without being lifted or damaged. Most FRP panels are designed to meet specific wind load requirements, making them suitable for areas prone to hurricanes or tornadoes. Overall, FRP roofing panels have demonstrated themselves to be a dependable and long-lasting solution for extreme weather conditions. They offer excellent resistance to water, UV rays, and wind, making them a popular choice for both commercial and residential buildings in areas with challenging climate conditions.

- Q: Do FRP roofing panels have any specific building code approvals?

- FRP roofing panels are required to have specific building code approvals, which can vary depending on the region or country. Each jurisdiction may have its own regulations and standards. However, in general, FRP roofing panels must meet certain criteria to receive these approvals. The building code approvals for FRP roofing panels typically consider factors like fire resistance, wind uplift resistance, impact resistance, and structural stability. These approvals ensure that the panels can withstand different environmental conditions and contribute to the safety and stability of the building. Manufacturers of FRP roofing panels must comply with the relevant building codes and standards set by local regulatory bodies to obtain building code approvals. This usually involves rigorous testing and certification processes conducted by independent testing laboratories. These tests assess the panels' performance in scenarios like fire exposure, wind pressure, and impact resistance. Builders and contractors should verify the specific building code approvals of FRP roofing panels before using them in construction projects. This can be done by checking the manufacturer's product documentation, which should clearly state the obtained approvals and certifications. By ensuring that FRP roofing panels have the necessary building code approvals, construction professionals can have confidence in their safety and performance. It helps them comply with local building codes and regulations and promotes the overall quality and longevity of the roofing system.

- Q: Can FRP roofing panels be used for both new construction and roof replacements?

- FRP roofing panels are suitable for new construction as well as roof replacements. They can be easily installed on different types of structures, such as residential, commercial, and industrial buildings. These panels are lightweight, durable, and have exceptional weather resistance, making them ideal for new roofs or replacing old or damaged ones. Moreover, their low maintenance requirements and simplicity of installation make FRP panels a cost-effective choice for any construction or replacement endeavor.

- Q: Do FRP roofing panels require a specific type of fastening system?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require a specific type of fastening system. The fastening system used for FRP roofing panels is typically designed to provide a secure and watertight installation. The specific type of fastening system will depend on the manufacturer's recommendations and the specific application requirements. Commonly, FRP roofing panels are fastened using screws or nails, but it is important to use the recommended fasteners provided by the manufacturer to ensure proper installation and avoid any potential damage to the panels. Additionally, the fastening system should be designed to accommodate the expansion and contraction of the FRP panels due to temperature changes, as this can affect the overall performance and lifespan of the roof. It is always advisable to consult with the manufacturer or a professional roofing contractor to determine the appropriate fastening system for FRP roofing panels based on the specific project requirements.

- Q: Are FRP roofing panels suitable for gymnasiums or sports facilities?

- FRP roofing panels prove to be a suitable option for gymnasiums and sports facilities. These panels, which are made of fiberglass reinforced plastic, are renowned for their strength and durability. They possess resistance against various weather factors like UV rays, moisture, and chemicals, making them perfect for both outdoor sports facilities and indoor gyms with high humidity levels. What sets FRP panels apart is their lightweight nature, making installation a breeze and saving time. Moreover, they offer exceptional thermal insulation, thereby reducing energy costs associated with heating or cooling the facility. Additionally, FRP panels can be translucent, allowing natural light to permeate the space. This aspect proves to be highly advantageous for indoor sports facilities that require optimal lighting conditions. When it comes to maintenance, FRP panels require relatively minimal upkeep compared to traditional roofing materials. They possess resistance against mold, mildew, and corrosion, ensuring a longer lifespan for the roofing system. Furthermore, cleaning FRP panels is a simple task that does not demand significant effort. To summarize, FRP roofing panels present numerous benefits, making them a fitting choice for gymnasiums and sports facilities. Their durability, resistance to weather elements, thermal insulation properties, and low maintenance requirements contribute to their cost-effectiveness and reliability for such structures.

- Q: Are FRP roofing panels compatible with different roof flashing materials?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels are generally compatible with different roof flashing materials. However, it is important to consider the specific requirements of the flashing material and ensure that it can be properly installed and sealed with the FRP panels. Some common roof flashing materials include metal, rubber, and PVC. Metal flashings, such as aluminum or galvanized steel, can typically be used with FRP roofing panels, as long as they are properly fastened and sealed to prevent water infiltration. Rubber and PVC flashings are also compatible with FRP panels, but it is essential to choose a flashing material that is designed for compatibility with FRP or consult the manufacturer's guidelines for proper installation. Overall, while FRP roofing panels can work well with various roof flashing materials, it is crucial to follow the manufacturer's recommendations and ensure proper installation for a watertight and durable roofing system.

- Q: Can FRP roofing panels be installed on both residential and commercial covered parking areas?

- FRP (Fiberglass Reinforced Plastic) roofing panels can be easily installed on covered parking areas, whether residential or commercial. These panels offer a multitude of advantages, such as durability, strength, and resistance to different weather conditions. They are also lightweight, making installation a breeze, and require minimal maintenance. FRP roofing panels are the perfect solution for safeguarding vehicles from the elements, whether it's a residential carport or a large commercial parking structure. Moreover, these panels come in various colors and designs, allowing customization to meet the aesthetic needs of both residential and commercial spaces. In conclusion, FRP roofing panels are a suitable choice for any covered parking area, be it residential or commercial.

- Q: Are FRP roofing panels prone to warping from nearby construction?

- The durability and resistance to warping of FRP roofing panels are well-known. However, their susceptibility to warping can vary depending on factors such as panel quality and the proximity and intensity of nearby construction activities. Although FRP roofing panels are designed to withstand external forces, they can still be affected by excessive heat, direct sunlight, or strong vibrations caused by nearby construction. If the panels are directly impacted by excessive heat or vibrations from the construction, there is a chance that warping may occur. To minimize the risk of warping, it is recommended to select high-quality FRP roofing panels specifically designed to withstand external forces. It is also important to consider the location and timing of nearby construction activities to help mitigate any potential risks. Precautionary measures, such as providing additional support or protection for the panels during construction, may be necessary. In conclusion, although FRP roofing panels are generally resistant to warping, it is crucial to carefully evaluate the circumstances of nearby construction and take appropriate action to ensure the stability and longevity of the panels. Seeking guidance from a professional roofing contractor or the manufacturer of the FRP panels can provide valuable insight in determining the best course of action in such situations.

- Q: Do FRP roofing panels require any special ventilation or air circulation?

- Yes, FRP (Fiberglass Reinforced Plastic) roofing panels do require special ventilation or air circulation, although the extent of the ventilation requirements may vary depending on the specific application and the environment in which they are installed. FRP panels are designed to withstand a wide range of temperatures and weather conditions, but proper ventilation is crucial to ensure their longevity and prevent potential issues. The primary reason for providing ventilation is to prevent the buildup of heat and moisture underneath the roofing panels. Without adequate ventilation, heat can accumulate, which may lead to thermal expansion and potential damage to the panels. Additionally, moisture buildup can result in condensation, which could cause corrosion or the growth of mold and mildew. To ensure proper ventilation, it is recommended to install a ventilation system that allows air to circulate beneath the roofing panels. This can be achieved through the use of ridge vents, soffit vents, or other types of ventilation systems that provide both intake and exhaust airflow. The specific design and size of the ventilation system will depend on factors such as the size of the roof, the climate, and the local building codes and regulations. It is important to consult the manufacturer's guidelines and recommendations for the specific FRP roofing panels being used, as they may have specific requirements for proper ventilation. Additionally, it is advisable to work with a professional roofing contractor who can assess the specific needs of your project and ensure that proper ventilation is provided. In summary, FRP roofing panels do require special ventilation or air circulation to prevent heat buildup and moisture condensation. Providing adequate ventilation is essential for maintaining the integrity and longevity of the panels and ensuring a healthy environment underneath the roof.

Send your message to us

FRP Roofing Panel - Fiber Reinforced Plastic Sheet Panel 0.5mm Thickness

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 20000 m²

- Supply Capability:

- 100000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords