Quick Assembly Slab Formwork System with Ring Lock Scaffolding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

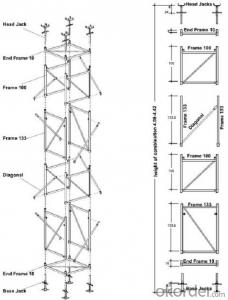

1. Brief introduction

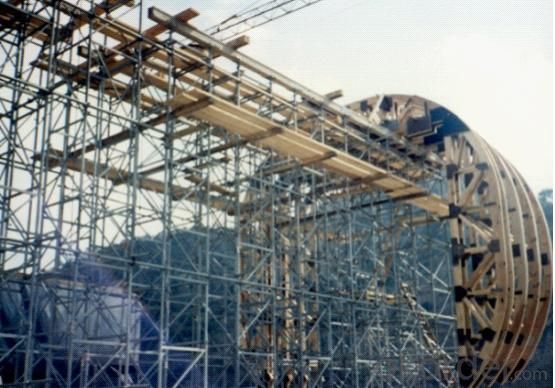

FA-TNOR system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, it is good choice for slab construction.

2. About the infill areas

Like RA-INST system, infill materials are necessary for small space or same special area. They are usually composed of timber beam, head-jack, scaffold support, and plywood as the below picture shown.

3. Competitive advantage

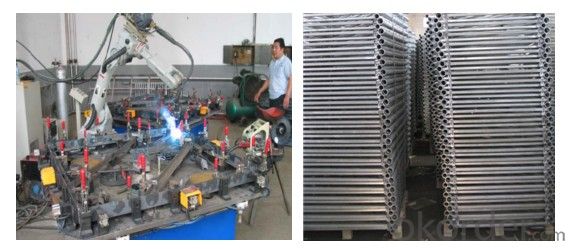

① Fast construction

The table formwork is pre-assembled; all the structural elements are connected by specific fastenings, so it is easily to move and turnover.

②Easy operation

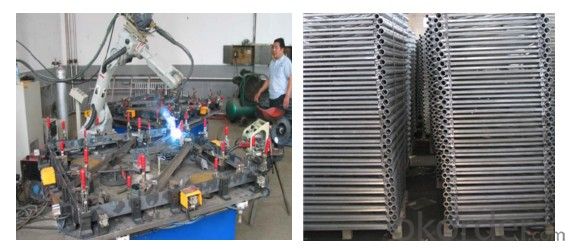

The formwork is composed of plywood, timber beam, channel beam, connectors and ring-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

③Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

④Mature system with specific tools for removing.

We afford trolley for FA-TNOR system, trolley is especially for shifting table formwork from the slab, it guarantees easy operation and safe removing.

4. Applications

- Q: Can steel tube couplers be used in both indoor and outdoor scaffolding applications?

- Yes, steel tube couplers can be used in both indoor and outdoor scaffolding applications. They are designed to provide a secure connection between steel tubes, ensuring stability and safety in various environments.

- Q: Can steel tube couplers be used in scaffolding projects with extreme temperatures?

- Yes, steel tube couplers can be used in scaffolding projects with extreme temperatures. Steel is known for its durability and resistance to temperature variations, making it suitable for use in a wide range of environmental conditions, including extreme temperatures. However, it is important to ensure that the couplers are properly designed and manufactured to withstand the specific temperature requirements of the scaffolding project.

- Q: Can steel tube couplers be used for both internal and external scaffolding applications?

- Yes, steel tube couplers can be used for both internal and external scaffolding applications.

- Q: Are steel tube couplers easy to assemble and disassemble in scaffolding?

- Yes, steel tube couplers are generally easy to assemble and disassemble in scaffolding. They are designed to provide a secure and reliable connection between scaffolding tubes, allowing for quick and efficient assembly and disassembly of the scaffolding system. The couplers are typically lightweight and compact, making them easy to handle and manipulate during the construction process. Additionally, they are designed with a simple locking mechanism that ensures a tight and secure connection, providing stability and safety to the scaffolding structure. Overall, steel tube couplers are widely used in the construction industry due to their ease of use and reliability in scaffolding assembly and disassembly.

- Q: What is the weight capacity of a steel tube coupler?

- The weight capacity of a steel tube coupler may differ based on several factors, including its specific design, size, and quality. Typically, steel tube couplers are engineered to endure substantial loads and possess substantial weight capacities. Nevertheless, it is crucial to consult the manufacturer's specifications and guidelines to ascertain the precise weight capacity of a particular steel tube coupler. These specifications are commonly furnished by the manufacturer and must be adhered to for the coupler's safe and effective utilization.

- Q: Are steel tube couplers suitable for scaffolding projects involving restrictive access or confined spaces?

- Yes, steel tube couplers are suitable for scaffolding projects involving restrictive access or confined spaces. Steel tube couplers are designed to connect steel tubes together, providing a secure and stable connection for scaffolding structures. They are commonly used in construction and scaffolding projects due to their strength, durability, and versatility. In situations where there is limited space or restrictive access, steel tube couplers offer several benefits. Firstly, they are compact and lightweight, making them easier to maneuver and install in tight spaces. Their small size allows for more flexibility in scaffolding design, enabling scaffolding structures to be constructed in confined areas where larger components may not fit. Additionally, steel tube couplers provide a secure and reliable connection, ensuring the stability and safety of the scaffolding structure. They are designed to withstand heavy loads and provide a strong grip on the steel tubes, minimizing the risk of any movement or collapse during construction or use. Furthermore, steel tube couplers are easy to assemble and disassemble, making them ideal for projects that involve frequent changes or adjustments. Their simple design allows for quick and efficient installation, saving time and labor costs. Overall, steel tube couplers are a suitable choice for scaffolding projects involving restrictive access or confined spaces. Their compact size, strength, and ease of use make them an effective solution for constructing safe and stable scaffolding structures in challenging environments.

- Q: Can steel tube couplers be used in scaffolding projects with limited access points?

- Yes, steel tube couplers can be used in scaffolding projects with limited access points. Steel tube couplers are versatile and can be easily connected to steel tubes to create a secure and stable scaffolding structure. They are commonly used in construction projects where access points are limited or restricted. Steel tube couplers are designed to be compact and lightweight, allowing them to be easily transported and maneuvered into tight spaces. They can be installed and adjusted with minimal effort, making them ideal for scaffolding projects with limited access points. Furthermore, steel tube couplers provide a strong and durable connection between steel tubes, ensuring the stability and safety of the scaffolding structure. They are specifically designed to withstand heavy loads and provide a secure platform for workers to perform their tasks. In conclusion, steel tube couplers are a suitable choice for scaffolding projects with limited access points. Their versatility, ease of installation, and strength make them an effective solution for creating scaffolding structures in challenging environments.

- Q: What is the difference between a fixed coupler and a swivel coupler?

- Various industries, including construction and scaffolding, utilize fixed couplers. These couplers are specifically designed to securely connect two tubes or pipes in a stationary manner, eliminating any possibility of rotation or movement. By utilizing two clamps, the fixed coupler ensures a stable and inflexible connection. In contrast, swivel couplers are another type of coupler that allows for rotation and movement between the connected tubes. This type of coupler is commonly employed in situations where adjustable angles or positioning are necessary. The swivel coupler typically consists of a clamp that can rotate around a central joint, enabling the connection of tubes at different angles or orientations. In conclusion, the primary distinction between fixed couplers and swivel couplers lies in their respective capabilities for movement. While a fixed coupler provides a secure and static connection, a swivel coupler offers the flexibility of rotation and adjustment between connected tubes. The choice between these two types of couplers is dependent on the specific requirements and intended use within a particular application.

- Q: Are steel tube couplers resistant to impact and shock loads?

- Steel tube couplers generally have resistance to impact and shock loads. Steel, being a robust and long-lasting material, can endure substantial amounts of impact and shock without any deformation or failure. The engineering and construction of steel tube couplers are specifically tailored to manage these kinds of loads. They find extensive usage in diverse industries and applications, including construction, infrastructure, and automotive sectors, where impact and shock loads are anticipated. Nonetheless, it is crucial to ensure the correct installation and maintenance of the couplers to optimize their ability to withstand impact and shock loads.

- Q: Can steel tube couplers withstand heavy loads in scaffolding?

- Steel tube couplers are specifically designed for heavy loads in scaffolding. Due to its strength and durability, steel is an excellent material for construction and scaffolding purposes. These couplers are engineered to ensure secure connections between scaffold tubes, guaranteeing stability and strength under heavy loads. They undergo rigorous testing and certification to meet industry standards and safety regulations, ensuring their ability to withstand the weight and pressure exerted on scaffolding structures. Additionally, steel tube couplers are widely used in scaffolding systems globally, further demonstrating their capability in handling heavy loads.

Send your message to us

Quick Assembly Slab Formwork System with Ring Lock Scaffolding

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches