Cost Effective Slab Formwork System with Quick - Striking Head Jack

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Detailed Product Description

1.Concrete slab formwork

2.Cost effective

Cost Effective Slab Formwork System with Quick - Striking Head JackDescription:

Brief introduction

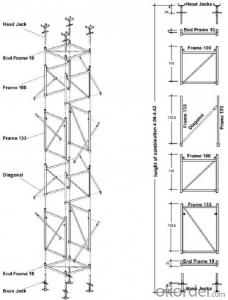

Alu-slab system is widely used for pouring slab concrete, especially for the building which has higher story height that only using props can’t meet requirements. The system guarantees quick assembly, simple structure and easily operation, with more important, it can achieve early & quick removing for parts materials; it is good choice for slab construction if you want to do cost effective construction.

Competitive advantage

① Cost effective

EA-REMO system has an important member which is called “quick-striking head jack”, with which will achieve quick & early removing for parts formwork system, it is fast to remove and turnover, so EA-REMO system guarantees cost effective construction.

②Flexible application

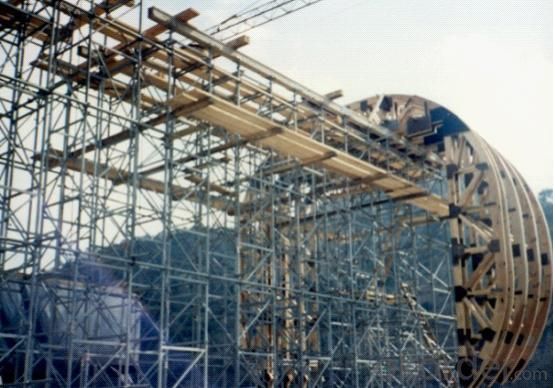

Unlike table formwork, EA-REMO system is composed of scattered element, so comparatively speaking, it will be easily to adapt to different building structures. No matter what shape your structure is, rectangular, circular, cambered, even irregular shape, it will always do a good work.

③Simple structure, easy operation.

The formwork is composed of plywood, main beam, secondary beam, connectors and cup-lock scaffolding support system. It’s easy to assemble for labors with simple structure. Special skill train is no needed.

④Height of scaffolding is adjustable

Table formwork is supported with adjustable scaffoldings; the scaffoldings can be pivoted in two directions for meeting the demand of different height with adjustable head jack and adjustable foot jack.

Applications

- Q: What are the key factors to consider when selecting steel tube couplers for a scaffolding project?

- There are several important factors to consider when choosing steel tube couplers for a scaffolding project. These factors include: - Strength and Load Capacity: It is crucial to select steel tube couplers that can handle the expected load of the scaffolding structure. This includes considering the weight of workers and any equipment or materials that will be placed on the scaffolding. - Compatibility: It is vital to ensure that the steel tube couplers are compatible with the specific type and size of scaffolding tubes being used. Incompatible couplers can cause instability and compromise the safety of the scaffolding structure. - Safety Standards and Regulations: It is essential to choose steel tube couplers that meet the safety standards and regulations set by relevant authorities. This ensures that the scaffolding structure is safe and compliant with legal requirements. - Durability and Corrosion Resistance: Steel tube couplers should be durable enough to withstand the demands of the scaffolding project. It is also important to consider the environmental conditions at the worksite, as corrosion-resistant couplers can extend the lifespan of the scaffolding structure. - Ease of Assembly and Disassembly: Selecting steel tube couplers that are easy to assemble and disassemble can save time and effort during the scaffolding project. Couplers with user-friendly features, such as quick-release mechanisms, can make the installation and removal process more efficient. - Reusability and Cost-effectiveness: Considering the reusability of steel tube couplers can significantly impact the overall cost-effectiveness of the scaffolding project. Couplers that can be easily reused for future projects can help reduce expenses in the long run. - Supplier Reputation and Support: It is crucial to choose steel tube couplers from a reputable supplier who offers reliable customer support. This ensures that any issues or concerns during the project can be promptly addressed, minimizing downtime and maximizing productivity. By considering these factors, one can make an informed decision when selecting steel tube couplers for a scaffolding project, guaranteeing the safety, durability, and efficiency of the scaffolding structure.

- Q: How is a steel tube coupler used in scaffolding?

- A steel tube coupler is used in scaffolding to connect two steel tubes together securely, providing stability and strength to the structure. It acts as a fastening device, allowing scaffolding components to be joined at various angles and configurations, ensuring a safe and sturdy platform for workers to access elevated areas.

- Q: Are steel tube couplers resistant to extreme temperatures or weather conditions?

- Steel tube couplers are known for their durability and ability to withstand extreme temperatures and weather conditions. These couplers are made from high-quality steel, which has excellent resistance to heat and cold. They are designed to maintain their strength and structural integrity even in extreme temperature fluctuations, whether it be high heat or freezing cold. Additionally, steel tube couplers are highly resistant to corrosion, making them suitable for use in various weather conditions, including rain, snow, and humidity. Overall, steel tube couplers are considered to be reliable and robust components that can withstand the harshest environmental conditions.

- Q: How do you properly install and secure steel tube couplers in scaffolding?

- Installing and securing steel tube couplers in scaffolding is a crucial step to ensure the stability and safety of the structure. Here is a guide on how to properly install and secure steel tube couplers in scaffolding: 1. Start by inspecting the steel tubes and couplers for any damage or defects. Ensure that they are in good condition and free from any cracks or deformities. 2. Determine the correct position and alignment for the couplers on the steel tubes. Measure and mark the desired location where the coupler will be placed. 3. Apply a thin layer of anti-seize compound or lubricant to the inside of the coupler. This will help with easy installation and prevent corrosion between the steel tube and coupler. 4. Slide the coupler onto the steel tube, aligning it with the marked location. Ensure that the coupler is fully seated on the tube and that there is no gap between the tube and the coupler. 5. Tighten the coupler using a scaffold spanner or wrench. Make sure to tighten it securely, but avoid over-tightening as it may damage the coupler or the tube. Check the manufacturer's recommendations for the recommended torque or tightening specifications. 6. Inspect the installed coupler to ensure it is properly aligned and securely attached to the steel tube. Ensure that there are no visible gaps or movement between the tube and the coupler. 7. Repeat the above steps for all other couplers that need to be installed in the scaffolding structure. 8. Once all couplers are installed, check the overall stability and integrity of the scaffolding. Ensure that all joints are secure and there is no noticeable movement or wobbling. 9. Regularly inspect the scaffolding during its use to ensure that the couplers remain securely fastened. Any loose or damaged couplers should be immediately replaced to maintain the safety of the scaffolding structure. It is important to note that the above steps provide a general guideline for installing and securing steel tube couplers in scaffolding. It is always recommended to refer to the manufacturer's instructions and guidelines specific to the couplers and scaffolding system being used. Additionally, it is essential to follow all relevant safety regulations and standards to ensure the proper installation and securement of these couplers in scaffolding.

- Q: Fastener type steel pipe scaffolding with wall pieces of what components

- Casing classification: rigid casing, flexible waterproof casing, steel pipe casing and metal casing and so on Flexible, casing re-test flexible waterproof casing for seismic fortification of the region, rigid waterproof casing for the pipe through the wall does not bear the vibration of the building casing, usually used in the construction of the basement, used to protect the pipeline or to facilitate the installation of iron pipe Casing classification: rigid casing, flexible waterproof casing, steel pipe casing and metal casing and so on

- Q: Building construction bowl button steel pipe scaffolding and fastener scaffolding which cost high

- XPS Extruded polystyrene board: polystyrene is used as raw material plus a simple toilet bowl 丿 stagnation on the lack of other raw materials and fire protection agent, by heating and mixing at the same time into the catalyst, and then squeeze the molding of rigid foam The EPS expansion polystyrene board: is a volatile liquid blowing agent containing polystyrene (eps) beads, preheated by heating after the mold in the mold, with fine closed-cell structure characteristics

- Q: Is it acceptable to erect a scaffold slightly out of plumb or level? Why or why not?

- slightly yes...but remember the higher you get the worst it gets...as in... an inch in 4 feet isnt bad, but that translates to 3 inches in 12 feet

- Q: How do you ensure proper alignment and stability when using steel tube couplers in scaffolding?

- Proper alignment and stability when using steel tube couplers in scaffolding can be ensured by following a few key steps. Firstly, it is important to select high-quality steel tube couplers that meet industry standards and have the appropriate load capacity for the specific application. Secondly, before connecting the tubes, it is crucial to ensure that the ends of the tubes are clean and free from any debris or rust that could hinder a secure connection. Additionally, using a hammer or mallet to lightly tap the couplers into place can help ensure a tight fit. Finally, regularly inspecting the scaffolding for any signs of movement, loosening, or misalignment, and promptly addressing any issues can help maintain stability and prevent accidents.

- Q: Are there any specific maintenance requirements for steel tube couplers in scaffolding?

- Yes, there are specific maintenance requirements for steel tube couplers in scaffolding. Firstly, it is important to regularly inspect the couplers for any signs of damage or wear. This can include checking for cracks, deformations, or any other structural issues that may compromise the integrity of the coupler. Any damaged couplers should be immediately replaced to ensure the safety of the scaffolding structure. Additionally, it is necessary to clean the couplers regularly to remove any dirt, debris, or rust that may accumulate on their surfaces. This can be done using a wire brush or any other appropriate cleaning tool. It is important to avoid using abrasive cleaners or materials that may scratch or damage the couplers. Moreover, lubricating the couplers with a suitable lubricant is recommended to prevent rust and ensure smooth operation. This can be done by applying a thin layer of lubricant to the moving parts of the coupler, such as the bolts or pins. It is important to follow the manufacturer's instructions and recommendations for the specific type of lubricant to use. Furthermore, it is crucial to store the couplers properly when not in use. They should be kept in a dry and well-ventilated area to prevent moisture buildup and rust formation. It is also important to avoid storing them in places where they may be exposed to extreme temperatures or corrosive substances. Lastly, regular training and education should be provided to the scaffolding personnel to ensure they are aware of the proper maintenance procedures and safety precautions related to steel tube couplers. This will help in preventing accidents and ensuring the longevity and reliability of the scaffolding structure.

- Q: How do steel tube couplers ensure the levelness and alignment of scaffolding platforms?

- Ensuring the levelness and alignment of scaffolding platforms is crucial, and steel tube couplers play a vital role in achieving this. These couplers securely connect steel tubes, creating a stable and rigid structure. To maintain levelness, steel tube couplers establish a strong connection between the tubes. This connection creates a continuous and even support system, preventing any sagging or tilting of the platform. The couplers, along with the rigidity of the steel tubes, evenly distribute the weight across the platform, minimizing any potential unevenness. In addition to levelness, steel tube couplers are essential for maintaining platform alignment. They fit precisely around the tubes, ensuring a tight and secure fit with no movement or slippage. By keeping the tubes in place, the platform maintains its alignment, avoiding any shifts or misalignments that could compromise stability and safety. Furthermore, couplers allow for easy adjustment and modification of the scaffolding platform. They can be quickly tightened or loosened, enabling workers to level and align the platform as needed. This flexibility ensures that the scaffolding can adapt to uneven terrain or changes in height, guaranteeing a stable and level working surface. In conclusion, steel tube couplers are an integral part of scaffolding systems, playing a crucial role in maintaining levelness and alignment. By securely connecting steel tubes and providing a rigid structure, these couplers create a stable and safe working environment for workers.

Send your message to us

Cost Effective Slab Formwork System with Quick - Striking Head Jack

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords