Forged Alloy Steel Round Bar 42CrMo4 Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

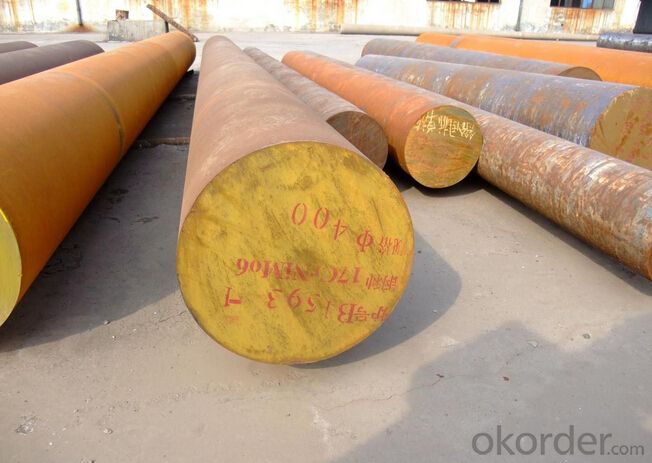

Forged Alloy Steel Round Bar 42CrMo4

Characteristics

1) Even material.

2) Good machinability and polishability.

3) High toughness and high plasticity.

4) High abrasive resistance in high temperature.

5) Excellent total hardenability.

6) Low deformability during heat treatment.

7) Better isotropy.

Application

1) Diecasting mould(mold, fixed block, upper die, jet nozzle, nitride thimble ).

2) Extrusion die(mold, supporting member, choke blocks).

3) Hot press die. (aluminum, magnesium, copper alloy)

4) Parts, such as cold cutting, overlap, hot shears, wearable parts.

5) Important parts for aviation industry.

Carbon Steel Round Bar | SS400, S235JR,Q235, ASTM A36, Fe360A, Fe360B,SM400A,080A15, SS41,E235B |

SAE 1020, AISI 1020, ASTM 1020, S20C, 20#, 050A20 | |

SAE 1045, AISI 1045, ASTM 1045, S45C, 45#,EN8, XC45, XC48, 45B, C45, CK45, CM45, 060A47, R683/IC45e | |

Alloy Steel Round Bar | 40Cr, DIN 1.7035, SAE 5140, AISI 5140, ASTM 5140, SCr440, 41Cr4, 530A40, 42Cr4, 40X, R683/VII3 |

SAE4140,42CrMo, 42CrMo4, DIN 1.7225, SCM440,EN19, 42CD4, 708M40, R683/II3 | |

SAE 4340, 40CrNiMoA, EN24, SNCM439, 817M40,40XMA, R683/III4 | |

SAE 8620,,AISI 8620, ASTM 8620, 20CrNiMo,SNCM220, 805M20 | |

SAE52100, AISI52100,ASTM E52100, GCr15, SUJ2, 100C6, 100Cr6, 1.3505, 534A99, IIIX15 |

Product show

Workshop show

Shipping

1. FedEx/DHL/UPS/TNT for samples, Door-to-Door;

2. By Air or by Sea for batch goods, for FCL; Airport/ Port receiving;

3. Customers specifying freight forwarders or negotiable shipping methods!

Delivery Time: 3-7 days for samples; 5-25 days for batch goods.

Payment Terms

1.Payment: T/T, L/C, Western Union, MoneyGram,PayPal; 30% deposits; 70% balance before delivery.

2.MOQ: 1pcs

3.Warranty : 3 years

4.Package Informations: 1) EXPORT, In 20 feet (GW 25 ton) or 40 feet Container (GW 25 ton)

2)as customer's requirement

Why choose us?

(1) The leading exporter in China special steel industry.

(2) Large stocks for various sizes, fast delivery date.

(3) Good business relationship with China famous factories.

(4) More than 7 years steel exporting experience.

(5) Good after-sales service guarantee.

- Q: What are the corrosion resistance properties of special steel?

- Special steels are known for their excellent corrosion resistance properties. These steels have specific alloying elements added to enhance their resistance to corrosion, making them highly resistant to rust and various corrosive environments. Their composition and surface treatment provide a protective barrier against chemical reactions, moisture, and other corrosive agents, ensuring their durability and longevity in various applications.

- Q: What are the requirements for special steel used in robotic applications?

- The requirements for special steel used in robotic applications include high strength and durability, resistance to corrosion and wear, excellent machinability, and the ability to maintain dimensional stability even under high temperatures. Additionally, the steel should have good weldability, be lightweight, and possess high fatigue resistance to ensure reliable and efficient performance in robotic systems.

- Q: How does special steel perform in high-temperature environments?

- Special steel performs exceptionally well in high-temperature environments. It has a high melting point, excellent resistance to heat and thermal shock, and can retain its strength and hardness even at elevated temperatures. This makes it highly suitable for applications such as aerospace, power generation, and automotive industries, where materials are exposed to extreme heat and require exceptional performance and durability.

- Q: How is special steel used in the production of valves and fittings?

- Special steel plays a crucial role in the production of valves and fittings due to its unique properties and characteristics. Valves and fittings are essential components used in various industries, including oil and gas, chemical, petrochemical, and power generation. Special steel, also known as alloy steel, offers superior strength, corrosion resistance, and durability compared to regular carbon steel. These qualities make it an ideal material for manufacturing valves and fittings that are subjected to high pressure, extreme temperatures, and corrosive environments. In valve production, special steel is commonly used for the valve body, bonnet, stem, and other critical parts. The valve body is responsible for housing the internal components and sealing the flow of fluids or gases. Special steel's high tensile strength and resistance to deformation ensure the valve body can withstand the pressure and maintain a tight seal, preventing leaks. Similarly, special steel is used in the production of fittings, which are used to connect pipes or other equipment in a fluid or gas system. Fittings made from special steel can withstand high pressures, temperature fluctuations, and corrosive media, ensuring a reliable and leak-free connection. Special steel alloys, such as stainless steel or duplex stainless steel, are often selected for their excellent corrosion resistance. They can withstand harsh environments, including exposure to chemicals, saltwater, and acidic or alkaline substances. This corrosion resistance is crucial in preventing valve and fitting failure, maintaining system integrity, and avoiding costly downtime or accidents. Moreover, special steel can be tailored to meet specific requirements, such as high-temperature resistance, low-temperature toughness, or excellent wear resistance. This allows manufacturers to customize valves and fittings based on the specific application and operating conditions, ensuring optimal performance and longevity. In summary, special steel is extensively used in the production of valves and fittings due to its exceptional strength, corrosion resistance, and durability. Its properties allow valves and fittings to perform reliably in demanding environments, ensuring safe and efficient operations in various industries.

- Q: What are the main characteristics of alloy steel forgings?

- The main characteristics of alloy steel forgings include enhanced strength, durability, and resistance to wear and corrosion. They also offer excellent heat resistance and can withstand high temperatures. Additionally, alloy steel forgings possess good machinability and can be easily shaped and formed into various complex designs.

- Q: How does special steel perform in abrasive wear applications?

- Special steel is renowned for its outstanding performance in applications where abrasive wear is present. Its design specifically caters to endure the harsh conditions and high levels of abrasion that occur in diverse industrial processes. A notable characteristic of special steel is its remarkable hardness. It can effectively withstand the abrasive forces exerted by different materials, such as rocks, sand, or minerals, without experiencing significant wear or deterioration. Achieving this hardness involves a combination of alloying elements and heat treatment processes, which enhance the steel's ability to maintain its structural integrity even under extreme wear conditions. Furthermore, special steel often possesses a high level of toughness, allowing it to absorb impact and resist fracture or chipping. This property is particularly crucial in applications involving abrasive wear, where materials frequently collide and generate high levels of stress. The toughness of special steel enables it to withstand these impacts and sustain its performance over an extended period. Moreover, special steel exhibits excellent corrosion resistance, which is vital in abrasive wear applications that involve exposure to moisture, chemicals, or other corrosive agents. This resistance guarantees that the steel does not deteriorate or lose its effectiveness due to chemical reactions or oxidation, extending its lifespan and reducing the need for maintenance. To summarize, special steel excels in abrasive wear applications due to its hardness, toughness, and corrosion resistance. These properties enable it to endure the challenging conditions and high levels of abrasion encountered in various industrial processes, ensuring long-lasting performance and minimizing downtime.

- Q: How does special steel contribute to the automotive engine industry?

- Special steel plays a crucial role in the automotive engine industry by providing superior strength, durability, and performance to various engine components. The unique properties of special steel make it an ideal choice for manufacturing critical parts, such as crankshafts, connecting rods, camshafts, valves, and cylinder liners. One of the key contributions of special steel to the automotive engine industry is its exceptional strength and resistance to high temperatures. Special steel alloys are designed to withstand the intense heat and pressure generated within an engine, ensuring that these components maintain their structural integrity and functionality under extreme conditions. This durability translates into increased engine efficiency, reliability, and longevity. Moreover, special steel's superior mechanical properties, including high tensile and impact strength, allow for the production of lighter yet stronger engine components. By reducing the weight of these parts, special steel helps to enhance fuel efficiency and reduce emissions, making it an environmentally friendly choice for automotive manufacturers. Special steel also contributes to the automotive engine industry by enabling the production of more complex and precise engine components. The excellent machinability and formability of special steel alloys allow for intricate designs, tighter tolerances, and improved performance. This, in turn, contributes to the overall efficiency and power output of the engine. Furthermore, special steel's corrosion resistance properties are crucial in preventing engine components from deteriorating over time. The ability to resist rust and other forms of corrosion ensures that the engine operates at optimal levels for an extended period, reducing maintenance costs and improving overall performance. In summary, special steel's unique properties, including strength, durability, heat resistance, and corrosion resistance, make it an essential material in the automotive engine industry. Its contribution lies in providing superior performance, efficiency, and longevity to critical engine components, ultimately enhancing the overall driving experience for consumers.

- Q: What are the cost considerations when using special steel?

- When utilizing special steel, there are several factors to consider in terms of cost. To begin with, the cost of the raw materials required for the production of special steel can be significantly higher compared to regular steel. Special steel often incorporates alloying elements like chromium, nickel, or molybdenum, which tend to be more costly than the iron and carbon used in regular steel production. These alloying elements enhance the properties of the steel, resulting in increased strength, greater resistance to corrosion, or improved suitability for specific applications. Furthermore, the production process for special steel may entail additional steps or specialized equipment, leading to higher manufacturing costs. This can involve procedures like vacuum degassing, controlled cooling, or precision forging, all of which contribute to the quality and performance of the final product but also add to the overall expenses. Moreover, since special steel is often customized to meet specific requirements or industry standards, there may be additional costs associated with testing and certification. These can include non-destructive testing, material analysis, or third-party inspections to ensure compliance with the necessary specifications. These additional quality control measures can raise the overall cost of utilizing special steel. Lastly, the cost of special steel can also be influenced by its demand and availability. If there is high demand for certain types of special steel or if the supply is limited, prices may be driven up. This can be particularly pertinent to industries that rely on specialized steel grades such as aerospace, automotive, or oil and gas. In conclusion, the cost considerations when using special steel encompass the higher cost of raw materials, the additional manufacturing steps, the requirements for testing and certification, and the overall dynamics of supply and demand in the market. However, it is important to note that the benefits and advantages of employing special steel, such as improved performance, durability, or specific properties, often outweigh the higher costs, making it a worthwhile investment for many industries.

- Q: What are the challenges in surface treating special steel?

- When it comes to surface treating special steel, a range of challenges can arise due to the unique properties and composition of the material. Some of the main challenges that need to be addressed are as follows: 1. Hardness: Special steels often possess a high level of hardness, which poses difficulties in achieving effective surface treatment. Traditional methods like heat treatment or chemical processes may not be sufficient to modify the surface properties without impacting the core strength. 2. Surface contamination: During the surface treatment process, special steels are vulnerable to contamination. Even the smallest traces of impurities or foreign materials can compromise the integrity of the treated surface. It is crucial to maintain a controlled environment and utilize clean equipment to minimize the risks of contamination. 3. Complex alloy composition: Special steels are typically alloyed with various elements to enhance specific characteristics, such as corrosion resistance or high temperature stability. This complex composition can make it challenging to find suitable surface treatment techniques that can effectively modify the surface properties without negatively affecting the overall performance of the alloy. 4. Adhesion and coating uniformity: Ensuring good adhesion and coating uniformity on special steel surfaces can be problematic. The surface characteristics and microstructure of special steels can make it challenging for coatings or treatments to properly and evenly adhere. Special attention must be paid to surface preparation and the selection of appropriate primers or coatings to ensure optimal adhesion and uniformity. 5. Heat sensitivity: Some special steels may be sensitive to heat during surface treatment processes. Excessive heat exposure can lead to changes in the material's properties, including structural alterations or deformation. It is essential to carefully control temperatures and employ suitable cooling methods to prevent any undesirable effects on the steel during the surface treatment process. 6. Cost: The process of surface treating special steel can be costly due to the specialized equipment, materials, and expertise required. Additionally, the challenges mentioned above can increase the complexity and time needed for surface treatment, resulting in higher costs. It is crucial to take these factors into consideration when planning and budgeting for surface treatment on special steel components.

- Q: How does special steel contribute to the defense industry?

- Special steel contributes to the defense industry in various ways. Its exceptional strength, durability, and resistance to corrosion make it an ideal material for manufacturing military equipment, such as tanks, submarines, and aircraft carriers. Special steel is also used in the production of firearms, missiles, and armored vehicles, providing enhanced protection and performance capabilities. Additionally, its heat resistance and ability to withstand extreme temperatures make it suitable for crafting jet engines and other critical components used in military aircraft. Overall, special steel plays a crucial role in ensuring the reliability, safety, and effectiveness of defense equipment.

Send your message to us

Forged Alloy Steel Round Bar 42CrMo4 Special Steel

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords