For elevator crane lift TVVB Flat flexible cables

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

For elevator crane lift TVVB Flat flexible cables

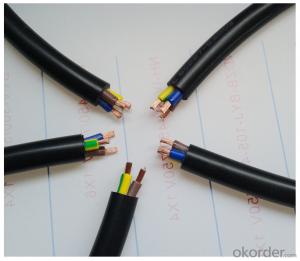

Application: Crane, elevator, lift and so on.

As control and signal cable for elevator as well as moving machine parts, its bending radius is smaller compared with round cables due to the closely packed shielded cores or bundles. It can be installed in dry and damp rooms.

TVVB flexible flat cable for elevator crane lift

Production Description:

1.PVC insulation, PVC sheath

2.With two steel wires

3.Rated voltage: 300/500V

4.Rate temperature: less than 70°c

5.Lifting height: less than 80m

6.Standard: National Standard GB5023-2-97,JB8734-98(IEC227)

Packaging Details:

1) Packing Lengths: 200m/roll, 300m/roll, 500m/roll, 100yard/roll, 200yard/roll, 300yard/roll

2) Inner packing: Wooden reel, plastic reel, and paper reel available.

3) Outer packing: Carton box, pull out box, pallet available.

4) Other packing available according to client's request.

Delivery Details:

FOB Shenzhen/HK.Delivery within 7-25 days or according to customer's request.

- Q: how many wires are allowed in a standard outlet box (i believe 3x2 1/2 deep). what do you do if you need more wires than are allowed?how many wires are allowed if i gang 2 boxes?i live in ontario, canada. thanks

- idk maybe 2?

- Q: Hello We have been running a room heater and humidifier from a bedroom wall electrical outlet for the last 4-5 months with no issue.2 days ago we noticed a burning/melting plastic smell when we ran the appliances for 10-15 mins. I checked the wall outlet after removing its cover and visually looks OK i.e. no blackening. I have not removed the actual sockets. Also, the appliances themselves seem to be OK i.e. no smell from them.Could the issue be in the wiring inside a wall? How to determine this? The smell seems to starts when we use this particular outlet only.If problem is not in outlet, then will the wall need to be broken into to determine the source of the problem? Is there a more sophisticated solution?What could have caused this sudden issue? A rodent? Water leakage thru the siding? Other ideas?Note that the circuit breakers have not tripped during this time to indicate overload etc.Thanks in advance for your opinions.Homeowner_ne

- Burning Smell From Electrical Outlet

- Q: Although metals and salts have similar lattice structures, metals make good materials for electrical wiring. Why aren’t salts used instead?

- Metals have electrons which rather leap from atom to atom, offering electric powered present day. Salts regularly have a steel and nonmetal at usual durations. The electrons are tightly shared between the ion pairs and are not loose to shuttle.

- Q: An incoming cable (line) is connected to a standard receptacle with the hot (black) wire attached to the upper screw (brass) and the white (common) wire attached to the lower screw (silver). The outgoing cable (load) is attached to the other two screws in the same manner. In my limited residential experience, the line cable will be attached to opposing screw contacts (upper 2 screws) with the second cable (load) attached to the bottom two contact screws on a standard electrical receptacle. In what conditions would these cable contacts be split like this? I have a short along this circuit somewhere and I am wondering if this is the problem?

- Actually that is an illegal wiring of a device in today's electrical field. All white (neutral) must not use a device for continuity. Proper wiring would be pigtailed or wire nutted. If the device fails so does the remainder of the circuit. losing the neutral on an appliance can lead to over voltage and fry the electronic power supply. My next question is do you have a short (breaker trips) or an open (no typical voltage across neutral and hot) And the worst offense of wiring is stabbing the wires in the back of the device. Never do this without a pig tail. The biggest reason trailer houses burn down is due to this huge wiring offense. Other problems you can search for: long nails or screws in walls, child puts long items through the back of the outlet. I have seen broken ground lead from plug shoved through back also. Mice chewing on wires to try and squeeze through holes. Smashed wires from GFCI being put in small metal nail on boxes of old construction. Just to name a few. The only time more then one screw should be used on receptacles is when you break the tab between the screws to split the receptacle.

- Q: Ready to exchange water heater, Q: . the toilet socket is 10 An, the wire is aluminum. Is it necessary to replace the socket or wire? If you have to change the line, you can also use the old trunking do not move only? . water heater to buy 1500W a good file or buy ..2000W third gear good? ...2000W third gear water heater can only be heated semi-bile water? How to control the heating of the whole box of water and semi-bile water? More

- . if you buy the water heater power does not exceed 2000W, then the 10A socket panel do not have to change, aluminum proposed replacement, replaced by 2.5 or 4 square copper wire can not change the line for . pay a single power 1500W You can, a number of stalls is only the difference between the heating time, and the power switch is easier to bad .3 stalls of the water heater has two heating rods, respectively, in the middle of the liner and the bottom of the so-called heating half of the meaning of water Is the above heating rod work, because the hot water density is low, so in the above, the temperature to stop heating, which is heating half gall bladder, the only user is the summer bath with the red, The province of heated whole bile water

- Q: I have two power acoustic 12sthey are 1600 to 1800 wattsI have a 1 ohm stable 3000 watt monoblock amp pushing them.It really bogs my lights down.what's the benefits of using a extra battery vs a capacitor.I have a spare battery I could use and also a capacitorand whichever is more beneficial can you explain how to wire it. What kinds of performance gain will I get out of both as far as base wise.

- The capacitor would be a better way to go. Another battery would make you have to upgrade your alternator also. So go with the capacitor. Run a 0 gauge wire from your battery to a distribution block 0 gauge in 2 4 gauges out one to the amp and one to the capacitor then ground the capacitor. It will store the unused power and help your battery out. Hope this helps.

- Q: I recently came across a big spool of rubber/plastic insulated electrical wiring. I cut into the metal with my knife and saw that it had an orange tint to it. I was excited because I thought it was copper but after I burned it and took it to a scrap yard the guy there stuck a magnet to it and said it wasn't copper. because it stuck to the magnet. So it's been about two months now and there's orange rust on it like Iron. but I know what steel wire looks like. This has that distinct copper orange in it but it's magnetic. Help me. I'm so angry and confused.

- possibly nickel/copper alloy used for heating elements (low temp) as it is insulated look up constantan wire

- Q: I have a lot of equipment in my local and I'm suffering about big cargo in electric wire for your knowledge voltage 220 Ventensity 30 Awire Demetre 2.5 mmwhat should I do for avoid the damaging of disgenctor or burning of wire

- The wires too small for 30A! You need to upgrade the wire size or lower the amperage! The set-up you now have is just begging for a fire! Be Careful! ;-)

- Q: Hi!Here is my situation. My husband installed a dishwasher for me over a year ago. The dish washer plugs into the same outlet my garbage disposal plugs into. The outlet in under my kitchen sink in the back of the cabinet. This outlet is connected to a switch located right behind my sink on the back splash. This is the problem. In order to use the dish washer, I have to unplug the disposal because the disposal will run the whole time if the switch is on. And so every time I need to use the disposal I have to crawl under the sink to plug it in. (VERY annoying) So I have been waiting for my husband to fix this for over a year and he keeps putting it off. So I want to know how I would go about doing this my self? I need to know what supplies I need, fittings? Basically step by step instructions and a materials list Hope someone can help. Thanks in advance!

- Ok you should be able to have them both plugged in at the same time. You need to open the outlet (turn off breaker first) and find the wires that go from the switch to the outlet. This would be easier if you had a picture, but i'll try my best. The outlet can work two different ways (most of them) you have to connect half of the outlet to the main power, then connect the other half to work with the switch.

- Q: What is the meaning of the national standard BVR?

- Some industrial and mining enterprises and chemical enterprises to the newly expanded technical transformation projects, power cables in parallel with the power supply, in parallel use, the two cables must be evenly distributed distribution, otherwise it will lead to thermal breakdown of the cable failure

Send your message to us

For elevator crane lift TVVB Flat flexible cables

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m

- Supply Capability:

- 50000 m/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches