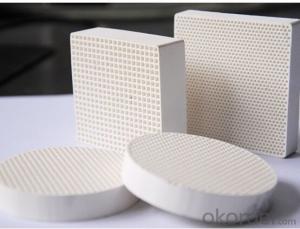

Ceramic Fiber Blanket Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

various density and thickness

used for industrial furnace and the sealing and insulating material of expanded gaps of furnace

Description

Ceramic Fiber Blanket is made by continuous processing method. The fiber interweave shapely after being needled. It has excellent tensile strength. The blanket do not contains any bonding agent.

Ceramic Fiber Blanket not only can resist the chemical species, but also the hydrofluoric acid, phosphoric acid and strong base. The Fiber Blanket have excellent capability of resisting the oil. After being dried ,it will repossess the thermal characteristic and the physical feature.

Our needled blanket has various density and thickness so that clients can have many choices. Which will bring the perfect insulating framework and profit.

Characteristic

Excellent Chemical Stability

Excellent Thermal Stability

Excellent Tensile Strength

Low Thermal Conductivity

Low Heat Storage

Product Series

1. 1050 Ceramic Fiber Spun Blanket HLGX-112

2. 1260 Ceramic Fiber Spun Blanket HLGX-212

3. High Purity Ceramic Fiber Spun Blanket HLGX-312

4. High Aluminum Ceramic Fiber Blown Blanket HLGX-412

5. High Zirconium Ceramic Fiber Spun Blanket HLGX-512

Technical Index

Classification Temperature | 1050 | 1260 | 1400 | |||||||

Code | HLGX-112 | HLGX-212 | HLGX-312 | HLGX-422 | HLGX-512 | |||||

Shrinkage on Heating (%) | 950°C×24h≤-3 | 1000°C×24h≤-3 | 1100°C×24h≤-3 | 1200°C×24h≤-3 | 1350°C×24h≤-3 | |||||

Theoretical Thermal Conductivity (W/m·k) (128kg/m3) | (200°Caverage) | 0.045-0.060 | 0.052-0.070 | |||||||

(400°Caverage) | 0.085-0.110 | 0.095-0.120 | ||||||||

(600°Caverage) | 0.152-0.20 | 0.164-0.210 | ||||||||

Theoretical Density (kg/m3) | 96/128 | 128 | 96/128 | |||||||

Specification (mm) | 3600/7200/15000(L)×610/1220(W)×10/20/25/30/40/50(T) (422δ: 10/20/25/30) | |||||||||

Tensile Strength(25mm thick)MPa | ≥0.04 | |||||||||

AL2O3(%) | ≥44 | ≥45 | ≥45 | 52~55 | 38~40 | |||||

ZrO2 | - | 15~17 | ||||||||

AL2O3+SiO2(%) | ≥96 | ≥97 | ≥99 | ≥99 | — | |||||

AL2O3+SiO2+ZrO2(%) | — | — | — | — | ≥99 | |||||

Fe2O3(%) | ≤1.2 | ≤1.0 | ≤0.2 | ≤0.2 | ≤0.2 | |||||

K2O+Na2O(%) | ≤0.5 | ≤0.5 | ≤0.2 | ≤0.2 | ≤0.2 | |||||

Package | Plastic Bag Inside, Carton Box Outside | |||||||||

Quality Control System | ISO9001-2000, ISO14001-1996 | |||||||||

Welcome your enquiry at any time. We are pleased to serve you with high quality product in most competitive price th professional service.

- Q: How many degrees does the ceramic filter melt?

- Alumina made from tabular corundum can be used over 1800 degrees!SiC if there is atmosphere, protection will be higher, there is no atmosphere protection, because the existence of oxidation, generally not more than 1600.Corundum, mullite, 1750 degrees small meaning.

- Q: Ceramic filter in vacuum pressure enough, the ceramic plate does not suck pulp, what is the reason for analysis?

- The filtrate is not discharged smoothly.The filtrate can not be discharged in a timely and smooth manner, the new filtrate can not be sucked out, and the filtrate can not be continuously sucked out, so that the filter cake can not be adsorbed on the ceramic plate.

- Q: What are the materials that make up the ceramic mold?

- From the development trend of rice, the development of ceramic membrane preparation technology mainly in the following 2 aspects: one is the porous membrane research, to further improve the already commercialized inorganic ultrafiltration and microfiltration membrane, nanofiltration membrane with molecular sieve, the development function of gas separation membrane and pervaporation membrane: two in dense membrane research solid electrolyte membrane, ultra-thin metal and its alloy film and ion conduction ability is research hotspot. The commercial porous membranes are mainly ultrafiltration and microfiltration membranes, and their preparation methods are mainly particle sintering and sol-gel. The former is mainly used for making microporous filter membranes, and commercial A1203 films are prepared by particle sintering method.

- Q: The efficiency of ceramic filter is low. What's wrong with it?

- CleanThe cleaning of ceramic filter is divided into two parts: reverse flush cleaning (also useful gas) and combined cleaning. The purpose of cleaning is to discharge the particles from the hole to the ceramic filter board.Anti flushing and cleaning water filter after direct visual pressure can, generally between 0.08--0.12MPa, such as less than 0.05MPa, while the poor flushing effect without even washing effect, resulting in blocking accumulation eventually led to the ceramic filter plate hole plugging scrap. Replacing the filter element in time and ensuring the water pressure before filtration can provide stable backwashing water pressure.Combined cleaning by ultrasonic vibration, nitrate dissolution method for maximum remove blockage of backwash rushed out, the general ceramic filter every 8 hours of continuous work should stop cleaning 1 hours, such as the use of the old plate or the suction effect is poor, can strengthen cleaning (such as shorten the cleaning period, prolong the period of cleaning, increase the amount of nitric acid etc.).

- Q: Principle of chemical engineering drum vacuum filter, the faster the speed, the less the amount of filtrate obtained per turn, the more the amount of filtrate obtained per unit time?

- In unit time, the more turns of the drum, the greater the centrifugal force, the greater the rate of filtration in unit time, that is to say, the amount of filtrate in unit time is moreRotating drum vacuum filter, the greater the speed, the greater the filtration rate, but the shorter the time each turn, the amount of each filtrate will be reduced

- Q: Can the plate filter press pass through the filter plate?

- There are many types of pumps to be used, such as screw pumps, slag pumps, rotary pumps, piston pumps, and diaphragm pumps.

- Q: The working principle of ceramic filter

- Based on the work principle of ceramic filter function of the capillary, by using porous ceramic as filter media, a large number of small capillary action with solid-liquid separation equipment design principle using microporous ceramic disc filter in negative pressure, working conditions, characteristics of the microporous ceramic filter plate with its unique water impermeable, extraction of ceramic filter plate and external vacuum cavity the differential pressure tank suspension material under the action of negative pressure adsorption in the ceramic filter plate, solid material can not through the microporous ceramic filter plate is retained on the surface of the ceramic plate, and the liquid due to the hydrophilic effect of vacuum pressure difference and the ceramic filter plate is passed into the gas-liquid distribution device (vacuum barrel) efflux or recycling so as to achieve the purpose of solid-liquid separation.

- Q: Microporous ceramic filter plate cleaning

- For the use of a long time, the method 1, the effect is still no significant improvement, that is how to plug the ceramic filter plate regeneration? The ceramic filter plate with uneven or non sucking slurry can be removed, and oxalic acid or other acid liquid with certain concentration and certain temperature can be taken together to dredge the microporous of the ceramic filter plate. (do not recommend sulphuric acid)

- Q: Ceramic filter ceramic plate blockage, productivity reduction, how to clean, to achieve the best effect cleaning problems

- Replace ceramic filter plate:Different users because of pulp particle size and different characteristics, the service life is long and short of ceramic filtering plate. For the use of a long time and after the method 1 and 2, the effect of slurry suction is still very poor, we should consider replacing the new ceramic filter board.

- Q: What's the acid of the ceramic filter plate?

- Ceramic filter boards tend to clog and acid washing is used to dissolve and dredge blockages in their pores.

Send your message to us

Ceramic Fiber Blanket Ceramic Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords