Alumina Ceramic Foam Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

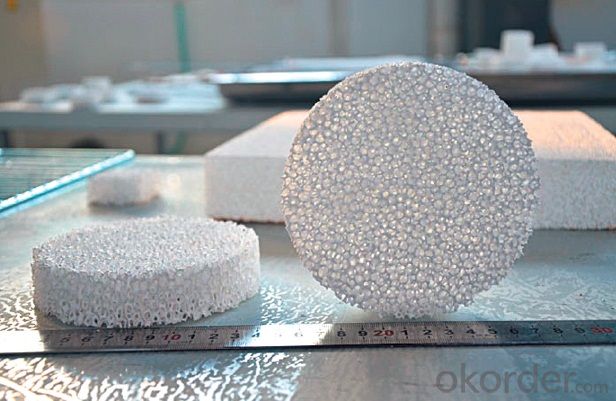

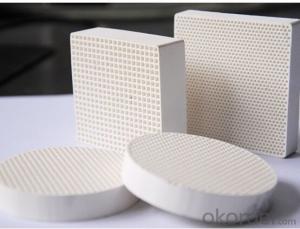

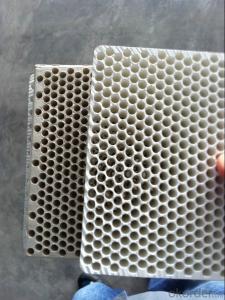

Alumina Ceramic Foam FiltersProfessional manufacurer

Precise Dimension Tolerance

Good Strength

ISO9001:2008 certification

Alumina Ceramic Foam Filter

Alumina Ceramic Foam Filter mainly use for filtration of aluminum and aluminum alloys in foundries and cast houses. With their excellent resistance to attack and corrosion from molten aluminum, Alumina Ceramic Foam Filter can effectively remove inclusions, reduce trapped gas and provide laminar flow, and then the filtered metal is significantly clearner. Clearner metal results in higher-quality castings, less scrap, and fewer inclusion defects, all of which contribute to bottom-line profit.

Alumina Ceramic Foam Filter apply to improve quality of alumina alloy casting and other non-ferrous alloy casting.

l Mend structure of crystalloid

l Improve function of machine

l Commutated function

Technical Data of Alumina Ceramic Foam Filter

Pore size (PPi) 10-60

Porosity (%) 80-90

Working temperature(°C) 1100

Bending Strength (Mpa) 0.6

Compression Strength (Mpa) 0.8

Thermal Shock Resistance(times/1100°C) 6

The size are available in square, round and custom geometric shapes; sizes ranging from 10mm up to 600mm, and thicknesses from 10-50mm. The most common porosities are 10ppi, 20ppi, 30ppi, 40ppi. The big alumina foam filter are available in size: 7’,9’,12’,15’,17’,20’,23’.

- Q: The ceramic filter suddenly did not smoke, and later he was all right. What's the reason?

- The size of ceramic filter is generally on both sides of the vacuum tank, such as 50 square meters with 5 square meters of ceramic filter / ring ceramic filter plate combination (possible), there are 10 discs, the ceramic plate left a vacuum tank on the left of the 5 disc for filtration, vacuum filtration tank for the ceramic plate on the right right of the 5 disc. If a vacuum system temporarily fails, it may cause poor suction, no suction, and a normal operation at the other end.

- Q: What are the poor filtration effects of vacuum disc filters?

- The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.On the other hand, as the spindle speed slows down, the thickness of the slurry is thickened, and the moisture of the concentrate is also affected. For viscous material, ceramic filter with ceramic plate to work as filter media, when the cake is formed gradually into the porous filter medium filter cake itself, and the cake is not easy to form a viscous material, forming a dry cake appearance does not slow, the spindle speed is easy to reduce the water content of concentrate. Similarly, the spindle speed is accelerated, the cake formation time in the vacuum zone is shortened, and the slurry thickness is reduced, and the material can be improved for the easy molding material. But the spindle speed is too fast to be cleaned after each cycle of the ceramic plate. As for the viscous material, the cake is difficult to form after the spindle speed increases, and it will affect the capacity. Therefore, the use of ceramic filter should focus on the inherent nature of the concentrate to explore the best spindle speed.

- Q: What are the causes of the powder moisture in the ceramic filter?

- The main speed of the ceramic filter is too fast.The vacuum of ceramic filter is not enough.The cleaning of ceramic filter has not met the requirement.The ceramic filter plate has a near life and a serious blockage.The selection of ceramic filter plate is different.Too much residual of ceramic scraper after discharge.

- Q: What is the filtration accuracy of 50nm ceramic membrane?

- The filtration accuracy is the maximum particle size that the membrane can pass through.

- Q: What's the reason for high water content in filtration copper concentrate?

- Ceramic filter plate1) the service life of the ceramic filter plate has arrived.2), ceramic filter plate uneven in quality on the market, the production capacity of some ceramic products difference (table mask size is too large or pore size uniformity is poor as a result of suction effect is poor, short life), but the price is low, but some users in order to reduce the operation cost of ceramic machine, tend to choose low price the ceramic plate, sometimes a ceramic machine ceramic filter plate with several may be different, so do not get the expected effect in normal use.In addition, the concentrator slurry, especially metal slurry, is very powerful on the wear of ceramic filter plate, the mechanical strength and wear resistance of ceramic filter plate requirements (corundum has high mechanical strength, good abrasion resistance, especially suitable for metal slurry dehydration).When selecting ceramic filter boards, these two points should be taken as a reference.

- Q: Ceramic filter capacity.

- 60 square meters of ceramic filter power 35kW or so, a high degree of automation, each class can complete the operation.

- Q: Does the ceramic factory use hydrochloric acid?

- In order to avoid the possibility of plugging, ceramic filter plates with suitable aperture range of different manufacturers can be selected.

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q: How to determine the quality of ceramic fiber filter board simply?

- Ceramic fiber filter board, in fact, ceramic fiber board, also known as aluminum silicate, refractory fiberboard.

- Q: Can the ceramic plate filter the hot air?

- Ceramic filter by vacuum suction effect in the ceramic filter plate to cake drying purpose, ceramic filter plate needs cleaning and life, if you discover that the slurry sucking effect is poor or even grout should first consider the three aspects: the two factors of ceramic filtering plate of ceramic filter plate most likely, are fracture and hole plugging: rupture will lead to distortion and poor vacuum cleaning; plugging holes will cause the filter plate suction effect is poor even if grout, ceramic filter plugging hole, can strengthen the appropriate cleaning (such as shortening cleaning cycle, prolong the cleaning time, increase the amount of nitric acid, such as strengthening cleaning etc.) after the effect is still not improved, you should consider the life is approaching should be scrapped and replaced with ceramic filter plate new (replacement plate should not put new or different manufacturers is mounted on the same line, the most OK, complete replacement.).

Send your message to us

Alumina Ceramic Foam Filter Plate

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords