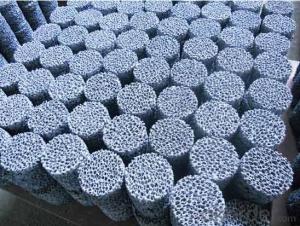

Ceramic Filter Plate for Iron Casting Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Silicon Carbide Ceramic Foam Filter

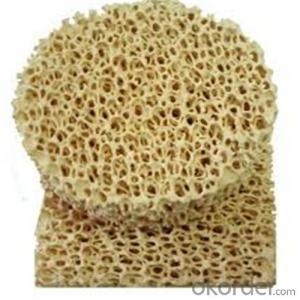

Silicon Carbide Ceramic Foam filter is justdeveloped as a new type molten metal filter to decrease casting flaw in recentyears. With its characteristics of light-weight, high mechanical strength,large specific surface areas, high porosity, excellent thermal shock resistance,erode resistance, high-performance, siliconcarbide ceramic foam filter is designedfor filtering impurities from molten Iron & Alloy, nodular cast ironcastings, grey iron castings and malleable castings, etc.

CNBM silicon carbide ceramic foamfilter ischaracterized by high porosity and mechanochemical stability and excellentresistance to thermal shock and corrosion from moltenmetal. It can effectively remove inclusions, reducetrapped gas and provide laminar flow when iron molten metalfiltrated, ceramic foam filter is machined to tight dimensionaltolerance during production, this combination of physical properties andprecise tolerance make them first choice for iron molten metal filtration.

TechnicalData of Silicon carbide ceramicfoam filter

BoreDensity(PPi) 10-40

Porosity(%) 80-90

Highestworking temperature (°C) 1500

BendingStrength (Mpa) 0.8

CompressionStrength(Mpa) 0.9

Thermal ShockResistance (times/1100°C) 6

DirectionsFor Use silicon carbide ceramic foamfilter

a) Dimensions Available:

Square shape:30-600mm

Round shape:φ40-φ300mm

Thicknessesfrom 10-50mm.

PPI:10P,15P,20P,25P,30P,40P

Ductile ironcastings use 10PPI, grey iron castings and tenacity iron casting use10PPPI,15PPI or 20PPI.

b)Filterable Melt Metal Weight Of Grey And Ductile Iron (10PPI):

Dimension | Ductile Iron (≤ kg) | Grey Iron (≤ kg) | metal volume of pouring (kg/sec.) | |

Ductile Iron | Grey Iron | |||

40×40×22 | 30 | 65 | 3 | 4 |

50×50×22 | 55 | 100 | 4 | 6 |

75×50×22 | 75 | 150 | 6 | 9 |

75×75×22 | 100 | 220 | 9 | 14 |

100×50×22 | 100 | 200 | 8 | 12 |

100×100×22 | 210 | 420 | 16 | 25 |

150×150×22 | 450 | 900 | 36 | 50 |

Weclome your enquiry about silicon carbide ceramic foam filter at any time. We are willing to supplyyou superior filters in most competitive price with professional service.

- Q: The ultrasonic wave of ceramic filter is not good. What's going on?

- The earliest filtration was mostly gravity filtration, which was followed by pressure filtration to increase the rate of filtration, followed by vacuum filtration. The drum vacuum filter invented in the early twentieth Century realized the continuous operation of the filter. Since then, various types of continuous filters have appeared. Intermittent operating filters (such as plate and frame press filters) are developed for automatic operation, and the filtration area is becoming larger and larger. In order to obtain the filter residue with low moisture content, the mechanical press filter has been developed.

- Q: Influence factors of ceramic filter

- (1) the particle size and the distribution of the material match the microporous of the ceramic filter plate. Although the ceramic filter plate aperture is bigger, easy to suck the pulp, but easy to cause the ceramic filter board to block up.(2) the ceramic filter plate with the same ceramic filter plate with high pore permeability and high water permeability is selected with high water permeability and good slurry absorption performance. The spindle speed is slow, the formation time of growth in the area of vacuum filter cake, production capacity increased gradually, but because the unit time of grout thickness and spindle speed slow is proportional to, so the ceramic filter capacity in a range of showing the highest.

- Q: What's the reason for high water content in filtration copper concentrate?

- Can the cleaning of ceramic plate meet the requirement?Such as cleaning of ceramic plate is not up to the requirements, plugging holes will increase the risk of ceramic plate, ceramic plate plug serious suction effect will become worse (filter cake moisture content increased, cake thickness reduction), cleaning of ceramic plate refers to washing and cleaning.Backwash to ensure that the water filter filter water pressure in the 0.1MPa or so, at least not less than 0.07MPa or less, it is necessary to consider before the filter water pressure is low or water filter element needs to be replaced.Joint cleaning to ensure that the ultrasonic can be no trouble, every time cleaning the amount of nitric acid up to standard. If the filtration effect is not ideal, the cleaning cycle can be washed from 45--60 every 8 hours, changed to 6--7 hours and cleaned for more than 1 hours.

- Q: Ceramic filter fineness thin mud suction is not what to do more

- With ceramic filter to treat pulp dehydration, the particle size is too large, the particles are easy to precipitate, the particle size is too small, too much mud, then the water content of the filter cake will increase, and the life of the ceramic filter plate will be reduced.

- Q: Microporous ceramic filter plate cleaning

- Ceramic filter comes with a combined cleaning system, usually to ensure backwashing normal, combined cleaning (nitric acid + ultrasonic + backwash) in place.

- Q: What's the acid of the ceramic filter plate?

- General ceramic filter running for eight hours or so, you need to stop for joint cleaning, general cleaning at an hour or so. When washing together, there is acid washing, usually concentrated nitric acid. The purpose is to dissolve the pores in the ceramic filter plate through nitric acid.

- Q: The vacuum of ceramic filter is not enough

- The vacuum degree of ceramic filter is about -0.08MPa, if the ceramic filter is less than 0.06MPa, the vacuum is not enough. If the vacuum of ceramic filter is not enough, it will influence the suction effect of ceramic filter (mainly the thickness of filter cake and water content of filter cake).

- Q: Ceramic filter suddenly do not smoke, a little later on their own good, what reason?

- How old the general ceramic filter suction main reason mud cake thickness is not much of a ceramic filter plate is different, because the ceramic filter backwash water, vacuum suction and nitrate are through the distribution valve, are often the same boat". See your description, you do not know the 5 line is about "5 disc or sideways 5 rows of ceramic plates, that is completely not suction or suction effect

- Q: What is the reason that the whole ceramic filter does not attract ore?

- Vacuum system failure, no vacuum or vacuum can not meet the requirements. Should check the vacuum pump and vacuum piping, distribution head, ceramic plate, such as failure or leakage.Whether the ore conditions are changed, such as pulp type, mud content, fineness, concentration, etc..

- Q: What about the leakage of the ceramic filter static and dynamic sealing points?

- The filtrate pump works to drain or recycle the water that has been pumped out. 6 、 cleaning system work, cleaning system includes backwashing (water pump pressure or height difference pressure), acid liquid (metering pump, automatic acid injection), ultrasonic (ultrasonic work), etc.. 7 、 control system and other electrical systems. In addition, the filter cake which is absorbed and dried on the ceramic filter plate is unloaded automatically by the scraper and then falls on the belt conveyor, and is conveyed to the concentrate storage yard by a belt conveyor. Other questions about ceramic filter, welcome to chat with me or look at my head

Send your message to us

Ceramic Filter Plate for Iron Casting Ceramic Foam Filter

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords