First Street Aluminum Foil Sheets - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

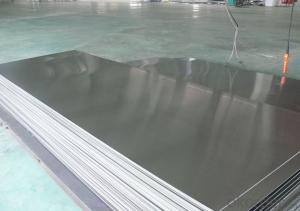

1.Structure of Product Description

Cold rolled aluminum sheet is widely used in the field of construction field and decoration field, etc. There are many different grades, such as: 1000 series, 2000 series, 3000 series, 5052,6063,8011, etc.

The temper is include H14, H22, H44,H112,F,O, H114,etc.

2. Main features of the product

a. price

b.Frist-Class Service.

c. Shortest service.

3. Image.

4. Product detailed sizes:

2000mm*2000mm,1000*1000MM, 1219mm*2438mm,1220mm*2440mm,

5. FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006 or others.

What is the width range?

---It is from 1000mm to 2500mm, etc.

---Normally it is from Japan, USA, ENGLISH, SINGAPORE, ETC.

What is your mainly products?

---Normally they are aluminum sheet,

checkered sheet, mirror finish aluminium sheet, aluminum casting coil, etc.

- Q: How can I make aluminum oxide?

- It turns out to be surprisingly difficult to do, because aluminum forms a skin of oxide which retards further oxidation. One way might be to react aluminum with sulfuric acid, getting aluminum sulfate in solution. Treat this with barium hydroxide; barium sulfate will precipitate out, leaving aluminum hydroxide in solution. Dry this and heat it, driving off the hydroxide as water and leaving aluminum oxide. I haven't tried this, so cannot guarantee that it will work.

- Q: AND WAT R THE THECNOLOGICAL ANDCOSTS AND BENEFITESOF USING ALUMINUM? what health -related and environment-related issues gave surface as aresult of its widespread use in society?

- airplanes are made from aluminum. certain beverages are also. aluminum is cheaper and lighter. the biggest problem is the amount of electricity that it takes to make aluminum

- Q: What does everyone think about replacing aluminum bats with wooded ones in high school. More and more cities are going back to wood.........why

- I don't have any particular beef against aluminum bats, but I also don't think they add anything to the game. If wooden bats are safer, then go with them, I say.

- Q: How do aluminum sheets perform in terms of vibration damping?

- Aluminum sheets possess exceptional vibration damping properties, renowned for their ability to effectively absorb and dissipate vibrations. These sheets, with their high density and stiffness, are capable of reducing both the amplitude and duration of vibrations. Consequently, aluminum sheets are deemed highly suitable for applications demanding vibration control, particularly in the aerospace and automotive sectors. Moreover, the lightweight nature of aluminum enables effortless installation and maneuverability, rendering it the preferred choice for vibration damping solutions.

- Q: What are the potential hazards or risks associated with the use and handling of aluminum sheets?

- <p>Safety issues related to aluminum sheets include the risk of cuts and lacerations from sharp edges, potential for eye injuries if aluminum particles or dust comes into contact with the eyes, and the risk of fire or explosion if aluminum dust is present in the air and ignited. Additionally, improper handling can lead to back injuries or other musculoskeletal disorders due to the weight of the sheets. Inhalation of aluminum dust over a long period may also pose health risks, although it's less common. It's crucial to use proper protective equipment and follow safety guidelines when working with aluminum sheets.</p>

- Q: what will happen when aluminum sheet is put into copper chloride solution?

- the chemical equation of the reaction, 2Al+3CuCl2=2AlCl3+3Cu, the phenomena when aluminum sheet is put into copper chloride solution: there is red solid generating on the surface of aluminum sheet.

- Q: What are the specific rules or benchmarks that must be followed when utilizing aluminum sheets for construction purposes?

- <p>Yes, there are special regulations and standards for using aluminum sheets in construction projects. These include material specifications, thickness, and strength requirements as per the American Society for Testing and Materials (ASTM) standards, such as ASTM B209 for aluminum sheet and plate. Additionally, the International Building Code (IBC) and local building codes provide guidelines for the use of aluminum in construction. These standards cover aspects like fire resistance, structural integrity, and weather resistance. Compliance with these regulations ensures safety, durability, and compliance with construction laws.</p>

- Q: This question asks for a list of various fasteners that are commonly used in the installation process of aluminum sheets.

- <p>There are several types of fasteners used for installing aluminum sheets, including: 1. Self-tapping screws, which create their own threads in the material. 2. Rivets, which join two pieces of material by compressing them together. 3. Pop rivets, a type of rivet that can be installed using a handheld tool. 4. Structural adhesives, which bond the sheets together without visible fasteners. 5. Welding, although not a fastener, it's a method used to join aluminum sheets permanently. 6. Mechanical fasteners like bolts and nuts, which are tightened to secure the sheets. 7. Clips and clamps, used for temporary or decorative installations. Each type has its own advantages and is chosen based on the specific requirements of the installation, such as load-bearing needs, aesthetic considerations, and the environment in which the aluminum sheets will be used.</p>

- Q: what family does aluminum belong to?its NOT the boron or aluminum family.i know its group 13. i need the family name.please help

- Aluminum is an orphan metal- (orphans appear in groups 3, 4, and 5 of the periodic table). They are called orphans simply because none belongs to a clearly defined family (like alkaline earth, transition metals, halogens, etc). Sometimes aluminum and the three elements below it in Group 3—gallium, indium, and thallium—are lumped together as the aluminum family, but that's not a clearly recognized family.

- Q: Are aluminum sheets suitable for aviation applications?

- Indeed, aviation applications can make effective use of aluminum sheets. The aviation industry extensively employs aluminum owing to its lightweight nature, impressive strength-to-weight ratio, and ability to resist corrosion. Aluminum finds applications in the manufacturing of aircraft, including critical components like the fuselage, wings, and structural elements. By utilizing aluminum sheets, the aircraft not only gain structural integrity but also experience reduced weight, thereby enhancing fuel efficiency and overall performance. Furthermore, the versatility of aluminum sheets allows for easy shaping and fabrication, making them highly adaptable for diverse aviation purposes.

Send your message to us

First Street Aluminum Foil Sheets - Aluminium Slab with Best Discount Price Low Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 200 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords