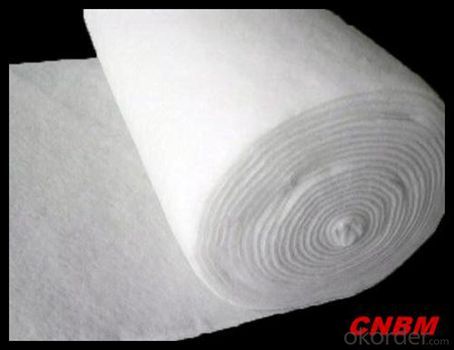

Geotextile Felt Fabric for Filament Woven Geotextile in Dykes and Dams Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Introduction:

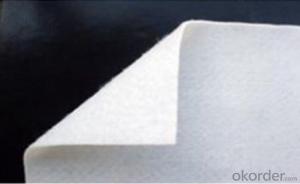

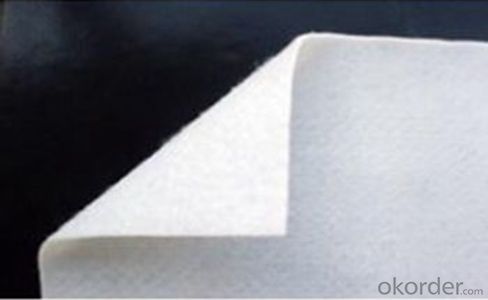

Description: High strength industrial synthetic fiber as the raw material, made through weaving technology.

Specification:

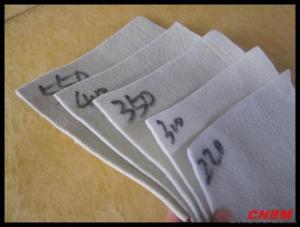

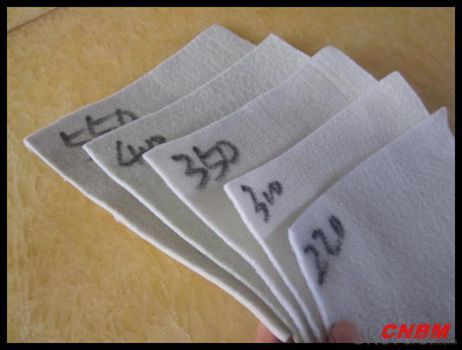

Nominal breaking strength in MD (kN/m): 35, 50, 65, 80, 100, 120, 140, 160, 180, 200, 250, width within 6m.

Property:

1. High strength, low deformation

2. Durability: steady property, not easy to resolved, air slaked and can keep the original property long term.

3. Anti-erosion: anti-acid, anti-alkali, resists insects and mould.

4. Permeability: could control the sieve size to retain certain permeability.

Application:

It is widely used in river, coast, harbor, highway, railway, wharf, tunnel, bridge and other geotechnical engineering. It could meet all kinds of geotechnical projects needs such as filtration, separation, reinforcement, protection and so on.

Functions

1.Separation

The isolation of the railway dregs and the roadbed, roadbed and the soft base, surface of the airdrome and parking lot and the groundsill, different dam materials. It isolates the soil and the gravel of two kinds different

granule pathway from the groundsill or other buildings.

2.Reinforcement

The highway, railway, soil-stone dam, breakwater, airport, backfill soil of retaining wall, slope protection, etc in which distributes the earth stress, prevents the side-displacement of the earth body and improves the earthbody stability.

3.ProtectionIt prevents the bank from being washed out, protects the bank and the

bottom, prevents the water and soil from being washed away

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

pecifications

geotextile fabric

permeability,filtration,easy for construction

ISO and CE certificate

Good quality and competitive price

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: What are the different applications of geotextiles in agriculture?

- Geotextiles have several applications in agriculture, including erosion control, soil stabilization, filtration, and drainage. They are commonly used to prevent soil erosion by acting as a barrier between the soil and water, helping to retain moisture and nutrients. Geotextiles also aid in soil stabilization by providing reinforcement and preventing soil movement. Additionally, they act as filters, allowing water to pass through while preventing the movement of fine particles. Lastly, geotextiles can be used for drainage purposes, facilitating the removal of excess water from agricultural fields.

- Q: Geotextile seam construction how to do

- Sewing of geotextiles All sutures must be carried out continuously (for example, spotting is not allowed). Before the overlap, the geotextile must overlap at least 150mm. The minimum stitch is at least 25 mm from the weaving edge (the edge of the material exposed). The seam of the geotextile seam is covered by a single line of thread lock. The line used for suturing should be a resin material with a minimum tension of more than 60N and is resistant to chemical corrosion and UV resistance comparable to or beyond the geotextile. Any "missing needle" on the sewn geotextile must be re-sewn in the affected area. It is necessary to take appropriate measures to prevent the soil, particulate matter or foreign matter from entering the geotextile after installation. Cloth lap according to the terrain and the use of functions can be divided into natural lap, seam or welding. Geotextile manufacturers, for your answer

- Q: What is the separation between the roof waterproof protective layer and the waterproof layer?

- The meaning of the protective layer and the isolation layer is not the same, figured out the role and meaning of nature know how to set up. 1, the protective layer of the waterproof layer contains a two-tier meaning. First, if there are other waterproof layer above the construction layer, due to the construction process may cause damage to damage to water, so need to do protective layer; Second, the roof is the function of the master or planting, the activities of personnel may cause damage to water , Need to do protective layer. 2, the role of the isolation layer is also divided into two kinds. First, to prevent the adverse effects of the two kinds of materials (incompatible), with the isolation layer for the interface, such as PVC coil and polystyrene foam insulation board, because the plasticizer in the membrane will migrate , The direct contact with the benzene plate will produce melt damage; Second, the coil surface of the rigid layer, may be due to thermal expansion and contraction deformation affect the waterproof layer, in the rigid layer of the larger part of the deformation, Too large and damage the waterproof layer, then need to set the isolation layer. There is a geotextile isolation layer between the waterproofing membrane and the pebble press material. 3, not all of the waterproof layer and the protective layer between the need for isolation layer. When the cement mortar is used as the protective layer, the cement mortar may be directly applied to the waterproof surface. When the flexible protective material (heat reflective coating, etc.) or the insulation layer is used, the isolation layer is not required.

- Q: How do geotextiles help with erosion control in slope protection projects?

- Geotextiles are used in erosion control and slope protection projects primarily to prevent the loss of soil and promote vegetation growth. These permeable fabrics act as a barrier against water flow, reducing the speed and erosive force of runoff. By trapping sediment and stabilizing the soil, geotextiles minimize erosion, enhance slope stability, and provide a suitable environment for plant establishment, ultimately protecting slopes from further deterioration.

- Q: Geosynthetics direct shear instrument reference standards which

- ISO.1, GB / T.1, ASTMD5321, JTGE50T1129, BiaozhunJiTuan-2017, SL / T235-1999. hope this helps.

- Q: Geotextile price specific how to develop?

- Each type of product in the market before the sale, the pricing will take into account all aspects of the factors, very strict and careful investigation, geotextile is also true. The first is the product quality is the second product specifications and standards to Hongxiang new material short wire geotextile, for example, sub-weight (80-1500g / ㎡), the quality standard is a requirement, divided into non-standard, by White A, Sinochem, ordinary GB, Paul GB, Dahua GB and so on. Ton price is generally between 4900-7500 yuan / ton, but the weight <200g, an increase of 100 yuan / ton; weight> 800g, an increase of 500 yuan / ton. 187 & lt; 6600 & lt; 5604

- Q: Do you want to make a geotextile?

- Is not the perforated tube, the cloth is not prevented from blocking the pipe hole. I am specializing in the production of geotextiles may be inside the trench inside the anti-seepage design, laying composite geomembrane

- Q: Project, what is the use of permeable geotextile?

- Geotextile main application areas: water conservancy projects: seawall, embankment, lake embankment project; reservoir reinforcement project; reclamation project; flood control and rescue. Highway and railway engineering: soft foundation reinforcement treatment; slope protection; road anti-reflective crack structure layer; drainage system; green isolation zone. Electrical engineering: nuclear power plant basic engineering; thermal ash dam project; hydropower project. Geotextile application characteristics: 1,8,7 Liu, 6,3,8 by, 3,6,0 reason, 2,31, due to the current geotextile production of synthetic fibers mainly nylon, polyester, polypropylene, B They have a strong anti-burying, corrosion resistance 2, geotextile for the permeable material, so it has a good anti-filter isolation function 3, non-woven geotextile due to structural fluffy, with good drainage performance 4, geotechnical Cloth has a good anti-puncture ability, so it has a very good protective performance 5, geotextile has a good coefficient of friction and tensile strength, with geotechnical reinforcement performance

- Q: 300g geotextile GB thickness is how much

- About two millimeters suggested to consult manufacturers. [`` Q`q``: 3271 plus 93,242] to the online to. You offer. The The

- Q: What are the advantages of using geotextiles in shoreline stabilization?

- There are several advantages of using geotextiles in shoreline stabilization. Firstly, geotextiles act as a barrier that prevents erosion and protects the shoreline from wave action. They provide stability to the soil by providing reinforcement and preventing the loss of sediment. Additionally, geotextiles allow for the filtration of water, which helps to maintain water quality and prevent the buildup of sediment. Furthermore, geotextiles are cost-effective compared to traditional methods of shoreline stabilization, as they require less maintenance and can be easily installed. Overall, geotextiles offer a sustainable and environmentally friendly solution for shoreline stabilization.

Send your message to us

Geotextile Felt Fabric for Filament Woven Geotextile in Dykes and Dams Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3000 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords