Mirafi 180n Filament Geotextile - The Best Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description

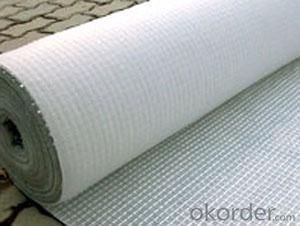

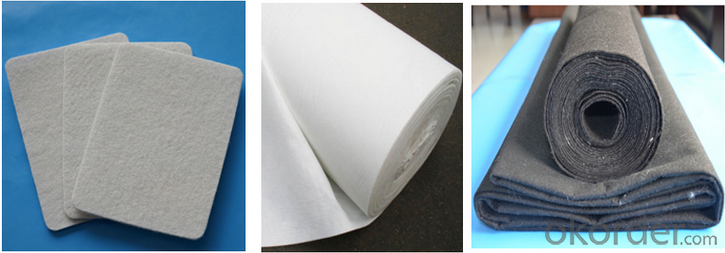

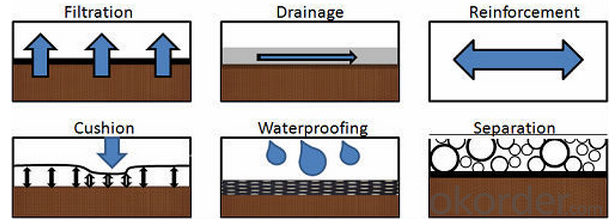

Geotextiles are permeable nonwoven fabrics used to separate,filter,reinforce, protect or drainage.Geotextiles allow filtration or separation of granular layers in roads and rail applications,used to protect membranes in landfill applications,used in coastal defence applications and used in landscaping to protect surfaces and structures from weeds and root growth.

Geotextiles are available as woven and non-woven .As liner protection, against physical damage, the non wovens are normally the answer.They are made up of fibers of polyester or polypropylene in random directions and punched together by needles during the manufacturing process.Geotextiles are commonly used to separate layers like clay and drainage and to protect liner from damage.

Product Details

Features:

Engineered to provide high strength and high elongation at break to ensure excellent resistance to damage during construction

Manufactured from high tenacity UV stabilised virgin polypropylene or polyester fibers which have been heavily drawn to ensure excellent long term durability in all soil types.

Manufactured using a randomly orientated web to provide completely isotropic properties,ensuring that high strength is not limited to a single direction.

Excellent uniformity with high permeability and low pore size for soil filtration.

Supplied to a maximum width of 8.0 meters,ensuring minimum waste over large construction areas.

100% polypropylene or polyester staple fibers ,needle punched and random network formation.

UV and rot resistant and biological degradation resistant.

Majority Process:

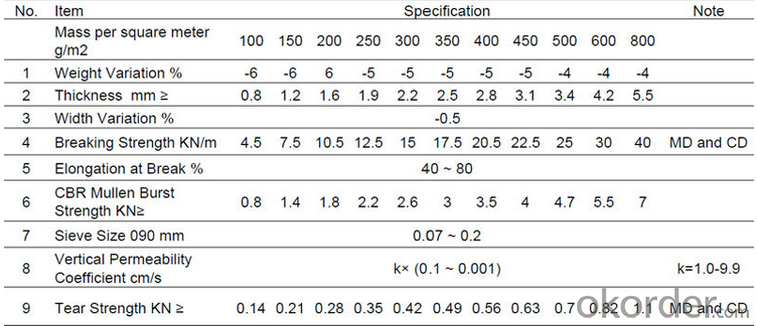

Specific Data:

FAQ:

1. How to order your geotextile?

a). Tensile strength in warp & weft direction

b). gram per meter

c). Width and length

d). Quantity

2. Payment term .

a) TT

b) LC AT SIGHT

3. Delivery time

a) 19-25 days after received your deposit .

4. What is MOQ ?

a) 2000 m2 as MOQ , we can also produce sample for you .

- Q: What is the difference between geotextile and impervious geotextile, geotextile and impervious geotextile?

- What is the difference between geotextile and impervious geotextile, geotextile and impervious geotextile?

- Q: Can geotextiles be used for reinforcement of embankments?

- Yes, geotextiles can be used for reinforcement of embankments. Geotextiles are commonly used as a separation, filtration, and reinforcement material in civil engineering applications. They can be placed between the soil layers to improve stability, prevent soil erosion, and enhance the overall strength of embankments.

- Q: Can the mortar be made directly on the composite geomembrane of the reservoir?

- Reservoirs on the composite geomembrane can be directly coated mortar composite soil film surface is geotextile can protect the PE film will not be chrome broken. South-to-North Water Diversion Project is directly in the composite geomembrane mortar.

- Q: How do geotextiles contribute to soil improvement in soft ground areas?

- Geotextiles contribute to soil improvement in soft ground areas by providing reinforcement and stabilization. They act as a barrier between the unstable soil and the overlying structures, distributing the load and reducing settlement. Additionally, geotextiles allow for water drainage while preventing soil erosion, promoting healthy soil conditions for growth and stability.

- Q: Can geotextiles be used for erosion control in agricultural fields?

- Yes, geotextiles can be used for erosion control in agricultural fields. They are commonly employed to stabilize soil, prevent the loss of sediment, and promote water infiltration. Geotextiles help reduce erosion caused by wind, water, or other environmental factors, thereby protecting the agricultural land and improving its productivity.

- Q: Can geotextiles be used in railway construction?

- Yes, geotextiles can be used in railway construction. They are commonly employed as a separation layer between subgrade soils and the ballast, helping to prevent the mixing of materials and providing stability. Geotextiles also aid in drainage, filtration, and erosion control, enhancing the overall performance and lifespan of railway tracks.

- Q: What are the advantages of using geotextiles in groundwater protection systems?

- Geotextiles offer several advantages in groundwater protection systems. Firstly, they act as a physical barrier, preventing the migration of pollutants and contaminants from seeping into the groundwater. This helps in safeguarding the quality and purity of the water source. Secondly, geotextiles provide filtration and separation capabilities, allowing water to pass through while retaining any suspended solids or particles. This enhances the overall efficiency of the groundwater protection system. Additionally, geotextiles are durable, resistant to degradation, and can withstand environmental stresses, ensuring long-term effectiveness in groundwater protection. Lastly, these materials are easy to install and maintain, reducing labor and maintenance costs associated with groundwater protection systems.

- Q: Can geotextiles be used in coastal protection projects?

- Yes, geotextiles can be used in coastal protection projects. Geotextiles are permeable fabrics that can effectively control erosion and stabilize soil in coastal areas. They are commonly used to prevent sediment loss, promote vegetation growth, and provide shoreline protection against wave action. Geotextiles can be installed as a barrier or a filter to retain sediment and prevent erosion, making them a valuable tool in coastal protection projects.

- Q: What are the different guidelines for geotextile installation in erosion control projects?

- There are several guidelines that need to be followed for geotextile installation in erosion control projects. Firstly, the geotextile must be placed on a properly prepared surface to ensure maximum effectiveness. The fabric should be tightly stretched and secured to prevent any movement or shifting. Additionally, the edges of the geotextile should overlap and be properly sealed to create a continuous barrier. It is also important to avoid any wrinkles or folds in the fabric as these can compromise its performance. Finally, regular inspection and maintenance should be conducted to ensure the geotextile remains intact and functional over time.

- Q: What is the role of geotextiles in geotechnical engineering?

- Geotextiles play a crucial role in geotechnical engineering as they are used to enhance the performance and stability of soil structures. They act as a barrier to prevent soil erosion, provide filtration to separate different soil layers, and increase the strength and stability of the soil. Additionally, geotextiles can also be used for drainage purposes, allowing water to flow through the soil while preventing the loss of fine particles. Overall, geotextiles are essential in geotechnical engineering for improving the overall effectiveness and longevity of various soil-based structures.

Send your message to us

Mirafi 180n Filament Geotextile - The Best Filament Spunbond Needle Punched Geotextile

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 900000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords