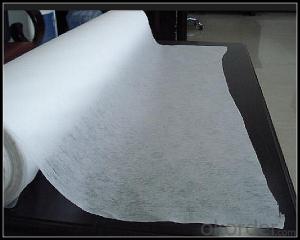

Quel Geotextile Non-Woven Geotextile Needle Punched PET Fabric Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

These geotextile filter fabric materials prevent the migration of fine soils to the spaces between rock particles. The migration of fine soil into your gabion structure can cause subsidence problems below or behind the gabion structure in time if not applied correctly and will stir up problems – especially in sandy soils. Clay soils do not generally require a geotextile filter fabric as they seldom leach through the basket section. We recommend using a suitable geotextile where the gabion is in contact with earth, this will limit any movement of soils through a gabion structure. In soft soil foundations especially and wherever overlaps or joins are required, we suggest a minimum overlap of 300mm(1 ft).

Non Woven Geotextile Application:

(1) artificial filling foundation movement of ground water.

(2) gravel filter layer surrounding the periphery of the drain pipe drain.

(3) in water conservancy projects wells, relief wells or inclined pipe filter.

(4) for retaining wall backfill reinforcement, or for anchored retaining wall panel.

(5) reinforced flexible pavements, crack repair roads, prevent the reflection cracks of pavement.

(6) in ternal vertical or horizontal drainage, dissipation of pore water pressure in soil.

(7) water impermeable geomembrane dam or embankment in the lower part of the back or the concrete.

(8) the isolation layer between the road ballast and subgrade, isolation layer or between the embankment and soft foundation.

(9) the isolation layer soil between highway, airport, railway ballast and artificial rockfill and soil fabric.

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

After-sales service

1.In order to provide customers with comprehensive technical support,we will provide technical and other related information upon request in a timely manner.

2.In required,we will appoint specialized technicians to the construction site to give technical trainings to construction people,and offer technical guidance throughout the whole construction process.

3.For damage due to shipment and delivery,after we receive the complaint,we will check the issure through provided pictures and videos.If our responsibility is confirmed,we wil offer free replacement.

4.When the construction is completed,as your request,our technical staff may participate in the final acceptance.

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: The difference between the geotextile and the geotextile

- I professional production geotextile geomembrane and other geotechnical materials, a professional construction of the welding team, wish smooth

- Q: What is the purpose of using geotextiles?

- The purpose of using geotextiles is to provide a wide range of functions in different construction and engineering applications. These functions include soil stabilization, erosion control, filtration, drainage, separation, and reinforcement. Geotextiles act as a protective barrier, improving the performance and lifespan of infrastructure projects such as roads, embankments, retaining walls, and landfills.

- Q: What are the main functions of geotextiles?

- The main functions of geotextiles include providing separation, filtration, reinforcement, and drainage in various civil engineering and construction applications.

- Q: How do geotextiles assist in slope stabilization?

- Geotextiles assist in slope stabilization by providing reinforcement and erosion control. They are placed on slopes to prevent soil erosion caused by water flow, thereby improving the overall stability of the slope. The geotextiles act as a barrier, preventing soil particles from being washed away while still allowing water to drain through. Additionally, they provide strength and reinforcement to the soil, reducing the risk of slope failure and landslides.

- Q: How do geotextiles improve soil stability?

- Geotextiles improve soil stability by providing reinforcement and preventing soil erosion. They act as a barrier against the movement of soil particles, effectively reducing the risk of slope failure and improving overall soil stability.

- Q: How do geotextiles affect noise pollution?

- Geotextiles can help reduce noise pollution by acting as a sound barrier or absorber in various applications such as road construction, landscaping, or building insulation. These specialized textile materials can help dampen sound waves, prevent their transmission, or absorb the noise, thereby minimizing the impact of noise pollution on the surrounding environment.

- Q: Geotextile grip test how to do? What is the step?

- Is said to be the strength test or the pull strength test. Can be based on relevant standards. For example: SL / T235-1999 standard, which has the relevant test method.

- Q: What is geotextile? Geotextile is what

- Geotextile, also known as geotextile, it is made of synthetic fiber through acupuncture or woven from the permeability of geosynthetics. Finished cloth for the cloth, the general width of 4-6 meters, the length of 50-100 meters. Geotextile is divided into a woven geotextile and non-woven geotextile. Geotextile has excellent filtration, drainage, isolation, reinforcement, anti-seepage, protection, with light weight, high tensile strength, good permeability, high temperature, anti-freeze, anti-aging, corrosion resistance characteristics. Geotextile is one of the geosynthetics, the application of geosynthetics originated in the fifties of the twentieth century, the domestic geotextile is one of the national eight five plan, China promulgated in 1998, "geosynthetics staple fiber Acupuncture non-woven geotextile "(GB / T-1998) standard, the current geotextile has been widely used in many areas.

- Q: How do geotextiles help in preventing the loss of fine particles in geocomposite drains?

- Geotextiles help prevent the loss of fine particles in geocomposite drains by acting as a filter barrier. They allow water to pass through while retaining the fine particles, preventing clogging and ensuring efficient drainage.

- Q: Are there any geotextiles on the upstream dam slope?

- Supply geotextile.

Send your message to us

Quel Geotextile Non-Woven Geotextile Needle Punched PET Fabric Price

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords