Fiberglass Mat Tissue Unidirectional Fabric 450gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

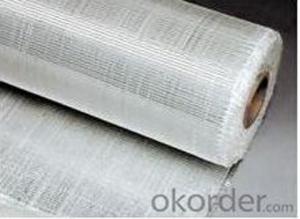

Fiberglass Unidirectional Fabric with Density 450gsm

Description

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Products Feature

• Easy to design, high strength in one direction.

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

• Craft: winding, pultrusion, hand lay up, etc.

Images:

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: What’s the advantage of you compared with other suppliers experienced in foreign trade?

A: We have been specialized in FRP products for over decades years and approved by many domestic companies. Except for our quality and price, we’re also able to give you the best service.

3.Q:Can you provide some samples?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: Can fiberglass mat tissue be used for corrosion-resistant applications?

- Yes, fiberglass mat tissue can be used for corrosion-resistant applications. It is commonly used as a reinforcement material in composite products that require resistance to corrosion, such as pipes, tanks, and structural components in harsh environments. The fiberglass mat tissue provides strength and durability while also enhancing the corrosion resistance properties of the final product.

- Q: Can fiberglass mat tissue be used for insulating concrete forms (ICFs)?

- Yes, fiberglass mat tissue can be used for insulating concrete forms (ICFs). It is commonly used as a reinforcement material in ICF construction due to its excellent insulation properties and ability to improve the overall strength and durability of the concrete structure.

- Q: Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue provides reinforcement to the composite pipe, enhancing its strength, durability, and resistance to corrosion.

- Q: What is the moisture resistance of fiberglass mat tissue?

- The moisture resistance of fiberglass mat tissue is generally quite high. The material is typically made from fiberglass strands that are tightly woven together, creating a dense and water-resistant surface. This makes it highly effective in applications where moisture exposure is common, such as in the construction industry for roofing, insulation, and waterproofing purposes. Additionally, fiberglass mat tissue is often treated with special coatings or additives that further enhance its moisture resistance, making it even more durable and reliable in wet or humid environments. Overall, the moisture resistance of fiberglass mat tissue is a significant advantage and contributes to its widespread use in various industries.

- Q: Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops. Fiberglass mat tissue is a thin, lightweight material made from fine glass fibers, which makes it an ideal choice for creating lightweight countertops. It provides strength and durability while also being easy to work with and mold into various shapes and sizes. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and heat, making it a suitable material for countertops that may be exposed to these elements. Overall, using fiberglass mat tissue for making lightweight countertops is a practical and efficient solution.

- Q: Can fiberglass mat tissue be used for corrosion-resistant coatings?

- Yes, fiberglass mat tissue can be used for corrosion-resistant coatings. It is commonly used as a reinforcing material in composite coatings to enhance their resistance against corrosion and other environmental factors.

- Q: How is fiberglass mat tissue manufactured?

- Fiberglass mat tissue is manufactured by first combining glass fibers with a binder material, usually a water-based emulsion. This mixture is then spread onto a conveyor belt or drum and passed through an oven to dry and cure the binder. The resulting mat is then rolled or cut into the desired dimensions and can be further processed or used as a reinforcement material in various industries such as construction, automotive, and aerospace.

- Q: What are the potential environmental impacts of using fiberglass mat tissue?

- The potential environmental impacts of using fiberglass mat tissue can vary depending on several factors. One potential impact is the extraction and production of the raw materials needed to manufacture fiberglass. The process of obtaining glass fibers involves mining and processing silica sand, which can lead to habitat destruction, soil erosion, and water pollution. Additionally, the production of glass fibers requires a significant amount of energy, which often comes from non-renewable fossil fuels, contributing to greenhouse gas emissions and climate change. Another environmental impact of using fiberglass mat tissue is the release of hazardous chemicals during the manufacturing process. Fiberglass production involves the use of resins, binders, and other chemicals that can be harmful to human health and the environment. These chemicals may be released into the air, water, or soil, potentially contaminating nearby ecosystems and posing a risk to wildlife and human populations. Furthermore, the disposal of fiberglass mat tissue at the end of its life cycle can also have environmental implications. Fiberglass is not easily biodegradable, and proper disposal methods are crucial to prevent it from ending up in landfills or being incinerated, both of which can release harmful substances into the environment. Recycling fiberglass can be challenging due to its complex composition, leading to a significant portion of it being discarded improperly. Lastly, the use of fiberglass mat tissue in certain applications, such as insulation or construction materials, can contribute to energy consumption and greenhouse gas emissions. For example, fiberglass insulation can require additional energy for manufacturing, transportation, and installation compared to alternative insulation materials like cellulose or mineral wool. In conclusion, the potential environmental impacts of using fiberglass mat tissue are diverse and range from habitat destruction and pollution during raw material extraction to the release of hazardous chemicals during manufacturing and difficulties in disposal and recycling. It is essential for manufacturers and consumers to consider these impacts and explore alternative materials and production processes that minimize harm to the environment.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Indeed, fiberglass mat tissue proves to be a fitting material for construction purposes. Renowned for its robustness, longevity, and ability to withstand diverse environmental conditions, this versatile substance is frequently employed in roofing, flooring, insulation, and wall panel installations. Fiberglass mat tissue emerges as an exceptional selection for construction ventures as it bestows reinforcement and stability upon a range of materials. When incorporated into roofing materials, it fortifies them against impacts, weathering, and fires. Similarly, it bolsters the strength and durability of flooring systems, rendering them capable of withstanding substantial loads and heavy foot traffic. Moreover, fiberglass mat tissue exhibits commendable insulation capabilities. It serves as an efficacious insulating component for walls, ceilings, and floors, enabling the maintenance of a comfortable indoor temperature while diminishing energy consumption. Its thermal and acoustic insulation properties render it an ideal choice for construction applications. Furthermore, its imperviousness to moisture, chemicals, and corrosion makes fiberglass mat tissue a suitable option for deployment in areas characterized by high humidity or exposure to harsh chemicals. Thanks to its resistance to decay, it guarantees durability, ensuring longevity in construction projects. To conclude, fiberglass mat tissue is an apt choice for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its adaptability and reliability have cemented its popularity within the construction industry.

- Q: How does fiberglass mat tissue perform in terms of moisture vapor resistance?

- Fiberglass mat tissue generally performs well in terms of moisture vapor resistance. The material itself is not permeable to moisture, meaning it acts as a barrier to prevent the passage of water vapor. This characteristic makes fiberglass mat tissue suitable for applications where moisture control is important, such as in roofing or insulation. The moisture vapor resistance of fiberglass mat tissue can be further enhanced by using it in conjunction with other materials, such as vapor barriers or moisture-resistant coatings. These additional layers can provide an extra level of protection against moisture infiltration, improving the overall performance of the fiberglass mat tissue in terms of moisture vapor resistance. However, it is important to note that the specific moisture vapor resistance of fiberglass mat tissue can vary depending on its thickness, density, and composition. Thicker and denser fiberglass mats generally offer higher moisture vapor resistance compared to thinner and less dense ones. Additionally, the presence of any manufacturing additives or coatings can also affect the material's moisture vapor resistance properties. In summary, fiberglass mat tissue is known for its good moisture vapor resistance capabilities, but its exact performance in this regard can be influenced by various factors. It is advisable to consult product specifications or manufacturers' recommendations to determine the specific moisture vapor resistance of a particular fiberglass mat tissue product.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 450gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 3000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords