Fiberglass Mat Tissue Unidirectional Fabric 350gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Properties

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

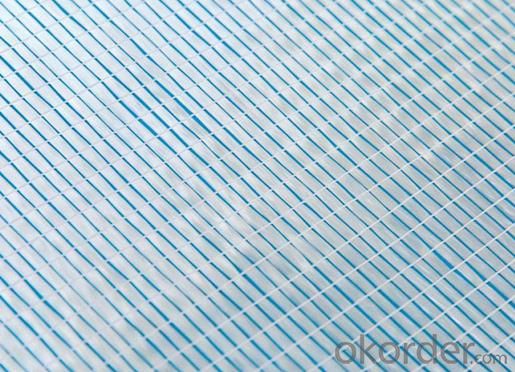

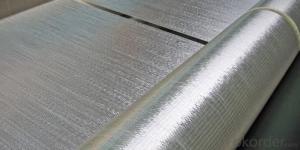

Images of Unidirectional

FAQ of Unidirectional

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What is the expected lifespan of fiberglass mat tissue in power generation applications?

- The expected lifespan of fiberglass mat tissue in power generation applications can vary depending on various factors such as the specific application, environmental conditions, maintenance practices, and quality of the material used. However, fiberglass mat tissue is typically designed to have a long lifespan and can often last for several decades in power generation applications when properly installed and maintained.

- Q: Is fiberglass mat tissue suitable for architectural applications?

- Yes, fiberglass mat tissue is suitable for architectural applications. It is commonly used as a reinforcing material for various architectural elements such as building facades, roofs, walls, and insulation. It provides strength, durability, and thermal insulation, making it an ideal choice for architectural projects.

- Q: Is fiberglass mat tissue compatible with different curing methods?

- Indeed, diverse curing methods are compatible with fiberglass mat tissue. This versatile material can be utilized in various curing processes, including hot press curing, autoclave curing, and vacuum bag curing. Specifically engineered to be compatible with different resins and curing temperatures, the mat tissue is capable of enduring the curing process without any detrimental consequences. Furthermore, the mat tissue is designed to possess excellent wet-out properties, enabling it to effectively bond with the resin during the curing process. Ultimately, fiberglass mat tissue proves to be a fitting option for a wide array of curing methods and can be effectively employed in numerous applications.

- Q: How is fiberglass mat tissue used in the production of storage sheds?

- Fiberglass mat tissue is used in the production of storage sheds to reinforce the structure and provide added strength and durability. It is typically applied as a layer in the construction process, serving as a reinforcement material for the shed's walls, roof, and floor. The fiberglass mat tissue helps to prevent cracking, increase resistance to weather elements, and improve overall longevity of the storage shed.

- Q: Can fiberglass mat tissue be used for insulation in pharmaceutical storage areas?

- Pharmaceutical storage areas can benefit from the use of fiberglass mat tissue for insulation purposes. This versatile material possesses outstanding thermal insulation properties and is widely used in various industries, including pharmaceuticals. Its ability to regulate temperature and provide insulation against heat transfer makes it an excellent choice for these storage areas. In order to preserve the quality and stability of medications and vaccines, maintaining the appropriate temperature is crucial. By reducing heat transfer between different areas and safeguarding the stored products from external temperature fluctuations, fiberglass mat tissue helps create a temperature-controlled environment. Furthermore, fiberglass mat tissue is lightweight, easy to install, and resistant to moisture, making it highly suitable for pharmaceutical storage areas that require cleanliness and hygiene. It can be effortlessly positioned between walls, ceilings, and floors, acting as a barrier against heat flow and effectively maintaining the desired temperature within the storage area. Moreover, fiberglass mat tissue is a non-combustible material, adding an extra layer of safety in pharmaceutical storage areas. It does not contribute to the spread of fire, thus ensuring the protection of valuable pharmaceutical products and minimizing the risk of fire-related accidents. In conclusion, fiberglass mat tissue is a reliable choice for insulation in pharmaceutical storage areas. It offers thermal regulation, moisture resistance, cleanliness, and fire safety, ultimately contributing to the maintenance of the necessary temperature and the preservation of the integrity and stability of stored medications and vaccines.

- Q: Can fiberglass mat tissue be used for roofing applications?

- Certainly, roofing applications can utilize fiberglass mat tissue. This lightweight and flexible material finds widespread use in the construction industry for a multitude of purposes, with roofing being one of them. It serves as a reinforcement layer, bolstering the strength and durability of roofing systems. Typically, the fiberglass mat tissue is saturated with bitumen or other waterproofing substances to establish a water-resistant shield atop the roof. Additionally, it contributes to augmenting the fire resistance and thermal insulation characteristics of the roof. Furthermore, fiberglass mat tissue's resistance to mold, mildew, and other prevalent roofing problems makes it an excellent option for roofing applications.

- Q: Can fiberglass mat tissue be used for insulating refrigeration units?

- Fiberglass mat tissue is indeed suitable for insulating refrigeration units due to its lightweight nature and outstanding thermal insulation properties. It finds extensive use in a wide range of applications where insulation is necessary, including refrigeration units. By minimizing heat transfer, the fiberglass mat tissue ensures that the internal temperature of the refrigeration unit remains stable, safeguarding the stored items from any external heat. Moreover, its moisture-resistant capabilities are particularly crucial in refrigeration units as they prevent condensation and help maintain the cooling system's efficiency. All in all, fiberglass mat tissue proves to be a reliable and effective option for insulating refrigeration units.

- Q: Can fiberglass mat tissue be used in automotive applications?

- Yes, fiberglass mat tissue can be used in automotive applications. Fiberglass mat tissue is a lightweight, non-woven fabric made from fine glass fibers. It is commonly used in the automotive industry for various applications such as reinforcing composite materials, improving mechanical properties, and reducing weight. In automotive applications, fiberglass mat tissue is typically used in the production of fiberglass-reinforced plastics (FRP) components. These components include automotive body panels, interior trim parts, engine covers, and various structural parts. Fiberglass mat tissue is often used as a reinforcement layer in the manufacturing process to improve the strength, stiffness, and impact resistance of these components. Additionally, fiberglass mat tissue helps to reduce the weight of automotive parts while maintaining their structural integrity. This is particularly important in the automotive industry as reducing vehicle weight can lead to improved fuel efficiency and lower emissions. Furthermore, fiberglass mat tissue offers excellent corrosion resistance, making it suitable for automotive applications where exposure to moisture, chemicals, and harsh environmental conditions is expected. Overall, fiberglass mat tissue is a versatile material that can be effectively used in various automotive applications to enhance performance, reduce weight, and improve durability.

- Q: How does fiberglass mat tissue contribute to the strength and durability of composite materials?

- Fiberglass mat tissue plays a crucial role in enhancing the strength and durability of composite materials. Firstly, the mat tissue acts as a reinforcement component by providing additional strength and rigidity to the composite structure. The fibers within the mat tissue are typically made of glass, which has high tensile strength and stiffness. These fibers are randomly oriented, creating a three-dimensional network that distributes and transfers stress throughout the composite material. This network of fibers helps to resist cracks and fractures, thereby increasing the overall strength of the composite. Furthermore, the mat tissue also acts as a barrier against delamination, which is a common issue in composite materials. Delamination refers to the separation of layers within the composite, which can weaken its structural integrity. The fiberglass mat tissue prevents delamination by bonding the layers together and improving the adhesion between them. This increased adhesion reduces the likelihood of interface failure and enhances the overall durability of the composite material. Moreover, fiberglass mat tissue helps to improve the impact resistance of composite materials. The random fiber orientation within the mat tissue creates a crisscross pattern, which enhances the composite's ability to absorb and distribute impact energy. This characteristic makes the material less prone to damage from external forces, such as impacts, vibrations, or mechanical stress. In summary, fiberglass mat tissue significantly contributes to the strength and durability of composite materials through reinforcement, delamination prevention, and enhanced impact resistance. Its unique characteristics and properties make it an essential component in various industries, including automotive, aerospace, construction, and marine, where the need for strong and durable materials is crucial.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Yes, fiberglass mat tissue can be used for reinforcing concrete. It is often used as a reinforcement material in construction for its high tensile strength and durability. The fiberglass mat tissue helps to increase the overall strength and structural integrity of the concrete, making it suitable for various applications such as building foundations, road pavements, and precast concrete products.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 350gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords