Fiberglass Mat Tissue Unidirectional Fabric 227gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Process

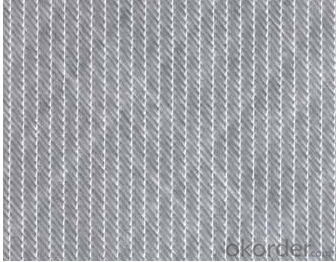

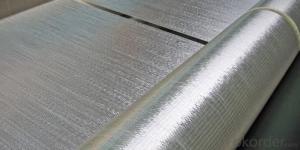

Fiberglass unidirectional fabric is the product combining the roving in certain angel of 0 ℃ or 90 ℃ with polyester yarn.

Properties

• Fiber straight arranged, fiber strength be ultimately used.

• No powder or emulsion, sink quickly, easy to operate.

• Easy to design, high strength in one direction.

Applications

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: winding, pultrusion, hand lay up, etc.

• Ultimate products: storage tank, tube, pultruded profiles, FRP body of boat, etc.

Specifications

specifications

Fibre type

0°Roving

90°Roving

Overall weight

Width

(g/㎡)

(g/㎡)

(g/㎡)

(mm)

EDW227

E-Glass

—

227

227

1524

EDW350

E-Glass

—

350

350

1524

EDW450

E-Glass

—

450

450

1524

EDJ600

E-Glass

480

120

600

1524

EDJ800

E-Glass

600

200

800

1524

EDJ1000

E-Glass

600

400

1000

1524

Packaging: Wrapped in PVC and placed within a cardboard carton.

FAQ of Woven roving combo mat:

Mainly be used as reinforced materials in the composite material industry.

• Matrix: unsaturated polyester resin, vinyl ester resin, epoxy resin and phenolic resin etc.

• Craft: pultrusion, RTM, hand lay up, etc.

• Ultimate products: pultruded profiles, FRP body of boat, insulation board, automobile body.

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How does fiberglass mat tissue compare to other insulation materials?

- Fiberglass mat tissue is a highly effective insulation material that offers several advantages over other insulation materials. Firstly, fiberglass mat tissue has excellent thermal insulation properties, which means it effectively prevents heat transfer and helps maintain a comfortable indoor temperature. This is particularly important in extreme climates where heat or cold can easily penetrate the building envelope. Additionally, fiberglass mat tissue is resistant to moisture, mold, and mildew, making it a durable and long-lasting insulation option. It does not absorb water, which helps to prevent the growth of mold and the degradation of the material over time. This is especially beneficial in humid environments or areas prone to moisture accumulation, such as basements or bathrooms. Furthermore, fiberglass mat tissue is non-combustible and has a high fire resistance rating. This makes it a safe choice for insulation, as it does not contribute to the spread of flames in case of a fire. It can also act as a barrier, preventing the fire from spreading to other areas of the building and offering occupants valuable time to evacuate. In terms of installation, fiberglass mat tissue is relatively easy to handle and install. It can be cut to fit any desired shape or size, allowing for flexibility during installation. It can also be used in various applications, including walls, floors, ceilings, and roofs, making it a versatile insulation material. Lastly, fiberglass mat tissue is an environmentally friendly option. It is made from recycled glass and sand, which helps reduce waste and conserve natural resources. It is also recyclable at the end of its lifespan, further minimizing its environmental impact. Overall, fiberglass mat tissue exhibits superior thermal insulation properties, durability, resistance to moisture and fire, ease of installation, and environmental sustainability, making it a highly favorable choice when compared to other insulation materials.

- Q: Can fiberglass mat tissue be used for insulation in cryogenic applications?

- Yes, fiberglass mat tissue can be used for insulation in cryogenic applications. Fiberglass is a versatile material known for its excellent thermal insulation properties. It has a low thermal conductivity, which means it is highly effective at reducing heat transfer. This makes it suitable for cryogenic applications where maintaining extremely low temperatures is crucial. Additionally, fiberglass is non-combustible and does not absorb moisture, making it ideal for cryogenic environments. It can be used as a layer of insulation in cryogenic storage tanks, pipes, and other equipment to prevent heat transfer and maintain the desired low temperatures.

- Q: Can fiberglass mat tissue be used for composite pipe manufacturing?

- Yes, fiberglass mat tissue can be used for composite pipe manufacturing. Fiberglass mat tissue provides reinforcement to the composite pipe, enhancing its strength, durability, and resistance to corrosion.

- Q: Are there any specific certifications or standards that fiberglass mat tissue must meet?

- Certifications and standards are necessary to guarantee the quality and appropriateness of fiberglass mat tissue for different purposes. The ASTM D 4601 standard is widely recognized and specifies the minimum requirements for glass fiber mats used in roofing and waterproofing systems. It covers various physical properties like weight, thickness, tensile strength, tear resistance, and water resistance. Apart from ASTM D 4601, fiberglass mat tissue may undergo testing based on its intended usage. For example, if it is used in the automotive industry, it may need to meet ISO 9001 or IATF 16949 standards, ensuring quality management systems and product consistency. Furthermore, fiberglass mat tissue used in construction or building materials should adhere to regulations set by organizations like the International Code Council (ICC), the American National Standards Institute (ANSI), or the Underwriters Laboratories (UL). These standards primarily focus on fire resistance, thermal insulation properties, and overall safety. Ultimately, the specific certifications and standards that fiberglass mat tissue must meet depend on its intended application and the industry it is used in. These standards are pivotal in ensuring the quality, performance, and safety of fiberglass mat tissue products.

- Q: Is fiberglass mat tissue resistant to termites and insects?

- Generally, termites and insects do not pose a threat to fiberglass mat tissue. This is because fiberglass is made from woven glass fibers, which are not a preferred food source for termites or insects. Furthermore, a layer of resin is typically applied to fiberglass mat tissue, further enhancing its resistance to pests. As a result, fiberglass mat tissue is a popular choice for construction and insulation in areas prone to termite and insect infestations. However, it is important to note that although fiberglass mat tissue itself is resistant to termites and insects, it does not provide complete protection against infestations. Therefore, it is advisable to implement additional measures such as proper sealing and regular inspections to ensure effective long-term pest control.

- Q: Can fiberglass mat tissue be used for bridge construction?

- Yes, fiberglass mat tissue can be used for bridge construction. Fiberglass mat tissue is a versatile material that offers several advantages. It is lightweight yet strong, making it suitable for use in bridge construction where weight considerations are important. Additionally, fiberglass mat tissue is highly durable and resistant to corrosion, which is crucial for the longevity and maintenance of bridges. It can also be easily molded into various shapes, allowing for flexibility in bridge design. Moreover, fiberglass mat tissue has good impact resistance and excellent fatigue performance, ensuring the bridge's ability to withstand heavy loads and constant traffic. Overall, fiberglass mat tissue is a reliable and cost-effective material for bridge construction.

- Q: Can fiberglass mat tissue be used for insulation in cold climates?

- Yes, fiberglass mat tissue can be used for insulation in cold climates. It is a commonly used material for insulation due to its low thermal conductivity and ability to trap air, providing effective insulation against cold temperatures.

- Q: Can fiberglass mat tissue be used for repairing fiberglass jet skis?

- Indeed, fiberglass mat tissue proves to be a valuable asset when it comes to restoring fiberglass jet skis. This material is frequently employed in fiberglass repairs due to its ability to fortify and reinforce afflicted regions. Its versatility allows for its use in a multitude of fiberglass repair scenarios, such as rectifying cracks or punctures found in jet skis. When skillfully applied, fiberglass mat tissue effectively reestablishes the jet ski's structural soundness, guaranteeing a resilient and enduring mending.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Fiberglass mat tissue can be suitable for soundproofing purposes, but its effectiveness may vary depending on the specific requirements and desired level of soundproofing. Fiberglass mat tissue is a lightweight and flexible material that can effectively absorb and dampen sound waves. It has good acoustic properties and can help reduce noise transmission, making it a viable option for soundproofing applications. However, it is important to note that fiberglass mat tissue alone may not provide sufficient soundproofing, especially in high-noise environments. For optimal results, it is recommended to combine it with other soundproofing materials such as acoustic foam panels or mass-loaded vinyl to enhance its soundproofing capabilities. Additionally, the thickness and density of the fiberglass mat tissue can also affect its sound absorption properties. Thicker and denser mats are generally more effective at attenuating sound waves, but they may also be less flexible and harder to install. In conclusion, while fiberglass mat tissue can contribute to soundproofing efforts, its suitability depends on the specific requirements, desired level of soundproofing, and the use of additional materials. Consulting with a soundproofing expert or conducting thorough research on the specific application is recommended to determine the most appropriate solution for effective soundproofing.

- Q: Can fiberglass mat tissue be used for reinforcing concrete?

- Yes, fiberglass mat tissue can be used for reinforcing concrete. It is often used as a reinforcement material in construction for its high tensile strength and durability. The fiberglass mat tissue helps to increase the overall strength and structural integrity of the concrete, making it suitable for various applications such as building foundations, road pavements, and precast concrete products.

Send your message to us

Fiberglass Mat Tissue Unidirectional Fabric 227gsm 1000mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords