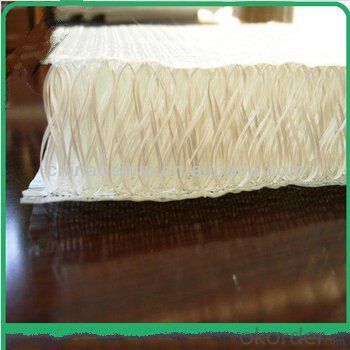

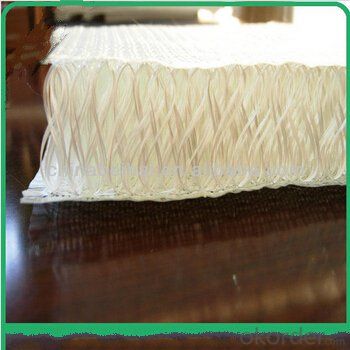

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 780g 200~2600 mm

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This mat is the multi-layered combination mat, generally made by mechanically stitching layers of roving or woven roving or chopped strand, in this case to one or both sides of synthetic fiber core (PP or PET), like a sandwich. The complex mat generally also be made from a combination of woven roving which are mechanically stitched with mats made of chopped strand to form the “bread”. Some complex mat even have no roving or fabric (i.e. complexes stitched from mats and veils without fabric layers). In all cases, the layers are mechanically stitched to the synthetic fiber core. It is mainly applied in the hand lay up, RTM and other close molding processes. ◎3-D spacer fabric construction is a newly developed concept. The fabric surfaces are strongly connected to each other by the vertical pile fibers which are interwoven with the skins. Therefore, the 3-D spacer fabric can provide good skin-core debonding resistance, excellent durability and superior integrity. In addition, the interstitial space of the construction can be filled up with foams to provide synergistic support with vertical piles. These products have broad application prospects in automobile, Locomotives, aerospace, marine, windmills, building and other industries.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Products Traits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ The structure of sandwich to increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| Application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Marine Applications Structural: ·Bulkheads ·Decks ·Hulls of racing catamarans and ribs(RIBS) Non structural: ·Fly-bridges ·Cabins ·Hatches ·Doors Interior parts: ·Furniture ·Partitioning ·Floor and ceiling panels ·Sanitary Cabinets Wind Power Applications ·Nacelles Cover ·Nose cone ·Blade Chemical industry-Corrosion Applications · The following double wall structures can be obtained using 3D fabric ·Double wall full GRP Tank ·Double wall tank lining Building Applications ·Interior and exterior wall covers ·stone strengthen ·radar domes ·industrial roofing ·amusement parks ·exhibition panels ·kiosks ·lightweight rigid covers | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge

Q: What is your MOQ?

A: Normally,4 rolls.

Q:How about your quality?

A: All of our products have obtained the GL and ISO9001 certificates ,Try a small order, you will have your judgements!

- Q: Can fiberglass mat tissue be used for mold-making?

- Typically, fiberglass mat tissue is not used for mold-making. This lightweight material is made up of randomly oriented glass fibers that are bonded together with a binder. It is commonly utilized in the insulation, construction, and automotive industries for reinforcement purposes. When it comes to mold-making, other materials like silicone, latex, or polyurethane are more commonly employed. These materials possess the necessary properties to create molds that are flexible and capable of reproducing intricate details accurately. Moreover, they are user-friendly and can be poured or brushed onto the original object to form a mold. Conversely, fiberglass mat tissue lacks the flexibility and accuracy required for mold-making. It is not designed to easily conform to complex shapes or capture fine details. Additionally, it may not provide the desired level of flexibility needed to safely remove the original object from the mold without causing damage. Therefore, it is advisable to utilize specific mold-making materials that are specifically designed for this purpose instead of attempting to employ fiberglass mat tissue.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable.

- Q: Can fiberglass mat tissue be used for electrical insulation?

- Fiberglass mat tissue can indeed serve as electrical insulation due to its impressive properties. Composed of fine glass fibers, this non-woven fabric possesses exceptional electrical insulation capabilities. Its ability to endure high temperatures and exhibit a high dielectric strength renders it ideal for a range of electrical applications. For instance, it finds regular use as an insulation material in electrical transformers, motors, generators, and other electrical equipment. By creating a barrier that hinders the passage of electrical current, the fiberglass mat tissue safeguards the components against potential electrical shocks or short circuits. Moreover, it boasts resistance against moisture, chemicals, and UV radiation, thereby further enhancing its suitability for electrical insulation purposes.

- Q: What is the tensile strength of fiberglass mat tissue?

- The tensile strength of fiberglass mat tissue varies depending on its specific composition and thickness, but it is generally known to have high tensile strength ranging from 200 to 600 MPa (megapascals).

- Q: Is fiberglass mat tissue suitable for agricultural applications?

- Certainly! Fiberglass mat tissue proves to be a suitable option for agricultural uses. Its versatility makes it an ideal material in the agricultural sector, providing numerous advantages. The resistance of fiberglass mat tissue to moisture, chemicals, and UV radiation makes it perfect for applications like greenhouse roofing, animal enclosures, and agricultural equipment. It possesses exceptional insulation properties, aiding in the regulation of temperature and safeguarding crops or livestock against harsh weather conditions. Moreover, fiberglass mat tissue is lightweight, easy to install, and long-lasting, making it an economical choice for agricultural projects. In conclusion, fiberglass mat tissue is a fitting material for a wide range of agricultural applications, ensuring durability, flexibility, and safeguarding for the farming industry.

- Q: How does fiberglass mat tissue compare to mineral wool insulation?

- Fiberglass mat tissue and mineral wool insulation are two common types of insulation materials used in construction and other industries. While both materials serve the purpose of providing thermal insulation, there are some differences between the two. Fiberglass mat tissue is made from fine glass fibers that are bonded together to form a mat. It is lightweight and flexible, making it easy to handle and install. Fiberglass mat tissue is also resistant to moisture, mold, and pests, making it a durable option for insulation. It has a high R-value, which measures the material's ability to resist heat flow, making it an effective insulator. On the other hand, mineral wool insulation is made from natural minerals such as basalt, diabase, or slag. It is typically denser and heavier than fiberglass mat tissue. Mineral wool insulation is known for its excellent fire resistance properties, as it is non-combustible and can withstand high temperatures. It also provides sound insulation, reducing noise transmission. However, mineral wool insulation can absorb moisture, which can reduce its effectiveness over time. In terms of thermal performance, both materials offer similar levels of insulation. However, fiberglass mat tissue tends to be slightly more efficient due to its higher R-value. Additionally, fiberglass mat tissue is generally more affordable compared to mineral wool insulation. In conclusion, fiberglass mat tissue and mineral wool insulation are both effective insulation materials. The choice between the two will depend on specific project requirements, such as fire resistance, sound insulation, cost, and moisture resistance. It is important to consider these factors and consult with professionals to determine the most suitable insulation material for a particular application.

- Q: What are the typical mechanical properties of fiberglass mat tissue?

- The typical mechanical properties of fiberglass mat tissue include high tensile strength, stiffness, and dimensional stability. Fiberglass mat tissue is known for its excellent resistance to breakage and deformation under stress, making it suitable for applications that require durability and structural integrity. It also exhibits good impact resistance, allowing it to withstand external forces without significant damage. Additionally, fiberglass mat tissue has a low coefficient of thermal expansion, meaning it is less prone to expanding or contracting with temperature changes, resulting in improved dimensional stability. These properties make fiberglass mat tissue a popular choice in various industries, such as construction, automotive, and aerospace, where strength and reliability are crucial factors.

- Q: Is fiberglass mat tissue suitable for soundproofing?

- Yes, fiberglass mat tissue is suitable for soundproofing. It is an effective material for absorbing and dampening sound waves, making it a popular choice for soundproofing applications in buildings, vehicles, and other structures.

- Q: Is fiberglass mat tissue recyclable?

- Yes, fiberglass mat tissue is recyclable.

- Q: Can fiberglass mat tissue be used for insulating metal buildings?

- Fiberglass mat tissue is indeed capable of insulating metal buildings. This lightweight and flexible material offers efficient thermal insulation for metal structures. It is frequently applied as a layer between the metal panels and the interior of the building, effectively hindering heat transfer and enhancing energy efficiency. Moreover, fiberglass mat tissue resists moisture and discourages the growth of mold or mildew, making it an excellent option for insulating metal buildings. Nevertheless, it is crucial to ensure correct installation in order to optimize its insulation capabilities and avoid any gaps or air leakage.

Send your message to us

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 780g 200~2600 mm

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords