Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1380g 200~2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

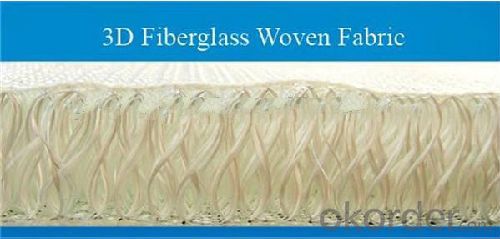

◎ 3D Fabric can be made of glass fiber, carbon fiber or basalt fiber. Hybrid fabrics also can be produced. The thickness of 3D Fiberglass Fabric ranges from 3.4 mm to 22.6 mm and the width of it measures no more than 3000 mm. Processed with resin, 3D Fiberglass Fabric gains an outstanding capability of anti-debonding, impact resistant, lightweight and high strength, thermal insulating and acoustic damping. 3D Fiberglass Fabric is often the first choice for many enterprises to manufacture framework members of automobile, locomotives, aerospace, ship, sports, wind generator, construction, decoration, ect.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Main Traits | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ The structure of sandwich to increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Q : Are you a factory or trading company ?

A: We have factories , can offer best quality product and reasonable price for you.

Q: Can you accept sample order?

A: Yes, we accept samples with little and reasonable charge

Q: What is your MOQ?

A: Normally,4 rolls.

- Q: How does the weight of fiberglass mat tissue affect its performance?

- The performance of fiberglass mat tissue is significantly affected by its weight. The weight of the tissue indicates the amount of glass fibers per unit area. Generally, a higher weight indicates a greater concentration of fibers, which results in improved strength and durability. To begin with, a heavier fiberglass mat tissue provides better tensile strength. The increased number of fibers in the tissue enables it to withstand higher levels of stress and strain without breaking or tearing. This makes it ideal for applications that require a high load-bearing capacity, such as structural components in the construction or automotive industries. Additionally, the weight of the tissue also impacts its stiffness and rigidity. A heavier mat tissue offers better dimensional stability, meaning it will maintain its shape and form even when subjected to external forces. This is crucial in applications where the material needs to retain its structural integrity, such as in boat hulls or wind turbine blades. Moreover, the weight of the fiberglass mat tissue affects its thermal and acoustic insulation properties. A higher weight is usually associated with better insulation capabilities, as the increased fiber density enhances the material's ability to trap air and reduce heat transfer or sound transmission. This makes it suitable for applications that require effective insulation, such as in buildings or industrial equipment. Finally, the weight of the fiberglass mat tissue can impact how easily it can be handled and installed. A lighter tissue may be more flexible and easier to manipulate, making it simpler to fit into complex shapes or tight spaces. Conversely, a heavier tissue might require additional support or equipment during installation. In conclusion, the weight of fiberglass mat tissue has a direct influence on its performance characteristics, including tensile strength, rigidity, insulation properties, and ease of handling. Therefore, it is crucial to consider the intended application and the desired performance requirements when selecting the appropriate weight of fiberglass mat tissue.

- Q: Is fiberglass mat tissue suitable for wastewater treatment applications?

- Yes, fiberglass mat tissue is suitable for wastewater treatment applications. It is commonly used in the construction of wastewater treatment tanks and pipes due to its corrosion resistance, durability, and ability to withstand harsh chemical environments. Additionally, fiberglass mat tissue is non-reactive to biological and chemical elements present in wastewater, making it an ideal material for such applications.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. It is a commonly used material in the manufacturing of nacelles due to its lightweight, high strength, and excellent weather resistance properties.

- Q: Can fiberglass mat tissue be used for ceiling insulation?

- No, fiberglass mat tissue is not suitable for ceiling insulation. While fiberglass mat tissue is commonly used in various construction applications, such as reinforcing plaster or other building materials, it is not designed or recommended for insulation purposes. When it comes to ceiling insulation, there are specific materials that are more suitable and effective, such as fiberglass batts, cellulose, or foam insulation. These materials are specifically engineered to provide thermal resistance and reduce the transfer of heat between the interior and exterior of a building. Using fiberglass mat tissue as ceiling insulation would not only be ineffective in providing proper insulation, but it may also pose safety risks. Fiberglass mat tissue is typically thin and lacks the necessary thickness to effectively insulate ceilings. Additionally, fiberglass insulation materials are known to release airborne particles and fibers, which can be hazardous to health if inhaled. Therefore, it is important to use the appropriate insulation materials that are specifically designed for ceiling insulation to ensure energy efficiency, comfort, and safety in your home or building.

- Q: What is the density of fiberglass mat tissue?

- The density of fiberglass mat tissue typically ranges from 0.3 to 0.6 grams per cubic centimeter (g/cm³).

- Q: Can fiberglass mat tissue be used for making insulation jackets?

- Yes, fiberglass mat tissue can be used for making insulation jackets. Fiberglass mat tissue is a lightweight material that offers excellent thermal insulation properties. It can effectively trap heat and prevent it from escaping, making it suitable for creating insulation jackets that provide warmth and insulation.

- Q: Does fiberglass mat tissue have any fire-resistant properties?

- Yes, fiberglass mat tissue does have fire-resistant properties. Fiberglass is inherently fire-resistant due to its composition. It is made from a combination of glass fibers and a thermosetting resin, which gives it its fire-resistant properties. When exposed to high temperatures or flames, fiberglass mat tissue does not easily ignite or burn. Instead, it resists the spread of flames and can help to contain a fire. This makes fiberglass mat tissue a suitable material for applications where fire protection is required, such as insulation, fire barriers, and fireproof panels. However, it is important to note that while fiberglass is fire-resistant, it is not completely fireproof and can still melt or burn under extreme conditions.

- Q: Can fiberglass mat tissue be used in structural applications?

- Yes, fiberglass mat tissue can be used in structural applications. Fiberglass mat tissue is a lightweight and flexible material that is commonly used as reinforcement in construction and engineering. It is often used in conjunction with other materials such as resin or concrete to enhance the structural integrity of various components. The high strength-to-weight ratio of fiberglass mat tissue makes it ideal for reinforcing structures such as walls, roofs, and floors. Additionally, fiberglass mat tissue is resistant to corrosion, moisture, and chemicals, making it suitable for use in various environments. Its versatility and durability make it a popular choice in structural applications.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Yes, fiberglass mat tissue is suitable for construction applications. Fiberglass mat tissue is a versatile material that is commonly used in construction due to its strength, durability, and resistance to various environmental factors. It is often used in applications such as roofing, flooring, insulation, and wall panels. Fiberglass mat tissue is an excellent choice for construction projects because it provides reinforcement and stability to various materials. It adds strength to roofing materials, making them more resistant to impact, weathering, and fire. Similarly, it enhances the strength and durability of flooring systems, making them capable of withstanding heavy loads and foot traffic. Additionally, fiberglass mat tissue is an effective insulation material. It can be used to insulate walls, ceilings, and floors, helping to maintain a comfortable indoor temperature while reducing energy consumption. Its thermal and acoustic insulation properties make it an ideal choice for construction applications. Moreover, fiberglass mat tissue is resistant to moisture, chemicals, and corrosion, which makes it suitable for use in areas with high humidity or exposure to harsh chemicals. It does not rot or decay, making it a long-lasting option for construction projects. In conclusion, fiberglass mat tissue is well-suited for construction applications due to its strength, durability, insulation properties, and resistance to various environmental factors. Its versatility and reliability make it a popular choice in the construction industry.

- Q: What are the different grades of fiberglass mat tissue available?

- There are several grades of fiberglass mat tissue available, ranging from lightweight to heavyweight. These grades are typically classified based on their weight per unit area, with lighter grades being thinner and more flexible, while heavier grades are thicker and more rigid. The specific grades and their corresponding weights may vary depending on the manufacturer, but generally, they are categorized as light, medium, and heavy.

Send your message to us

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1380g 200~2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords