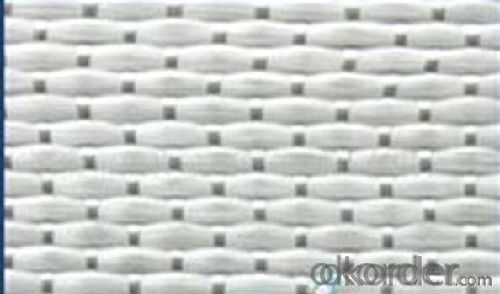

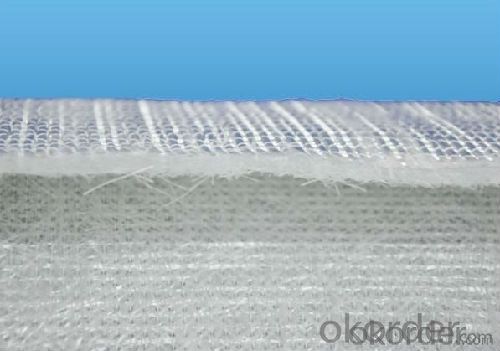

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1300g 200~2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description & application | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

◎ This mat is the multi-layered combination mat, generally made by mechanically stitching layers of roving or woven roving or chopped strand, in this case to one or both sides of synthetic fiber core (PP or PET), like a sandwich. The complex mat generally also be made from a combination of woven roving which are mechanically stitched with mats made of chopped strand to form the “bread”. Some complex mat even have no roving or fabric (i.e. complexes stitched from mats and veils without fabric layers). In all cases, the layers are mechanically stitched to the synthetic fiber core. It is mainly applied in the hand lay up, RTM and other close molding processes.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Advantages

◎ The structure of sandwich to increase strength, reduce product weight and better surface finish. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||

1. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

2. What is the Production Lead Time?

15-20 days for bulk production after confirm the order.

fiberglass fence panels fiberglass fence panels

3. What is your MOQ?

Our MOQ is 5000 kgs.

- Q: Does fiberglass mat tissue require any special treatment for UV resistance?

- Special treatment is required for UV resistance when using fiberglass mat tissue. This tissue is composed of fine strands of glass fibers which can be easily damaged by prolonged exposure to ultraviolet (UV) radiation. The degradation of the fibers due to UV rays can result in a reduction in strength and dimensional stability. To enhance the UV resistance of fiberglass mat tissue, manufacturers often apply a unique coating or treatment to the material. This treatment serves to safeguard the fibers from UV radiation and prevent their deterioration. The specific treatment employed may vary based on the intended application and the desired level of UV resistance. Furthermore, it is important to acknowledge that despite the special treatment, fiberglass mat tissue may still experience some degree of UV damage over time. It is therefore advised to minimize direct sunlight exposure whenever possible to ensure the longevity and performance of the material.

- Q: Does fiberglass mat tissue require any special surface treatments before application?

- Yes, fiberglass mat tissue does require special surface treatments before application. These treatments are necessary to ensure proper adhesion and bonding between the fiberglass mat tissue and the substrate it is being applied to. One common surface treatment is the application of a primer or bonding agent. This helps to improve the bond strength between the fiberglass mat tissue and the substrate. The primer or bonding agent is typically applied to the substrate and allowed to dry before the fiberglass mat tissue is applied. Another surface treatment is the removal of any loose or flaking material from the surface of the substrate. This can be done through mechanical methods such as sanding or grinding, or by using a chemical treatment to dissolve or remove the unwanted material. This step is important to create a clean and smooth surface for the fiberglass mat tissue to adhere to. In some cases, the surface of the substrate may need to be roughened or etched to provide a better bonding surface for the fiberglass mat tissue. This can be done using abrasives or chemical etching agents, depending on the type of substrate being used. Overall, the specific surface treatment required for fiberglass mat tissue will depend on factors such as the type of substrate, the desired bond strength, and the application method being used. It is important to follow the manufacturer's instructions and recommendations for surface preparation to ensure a successful application and long-lasting bond.

- Q: Is fiberglass mat tissue resistant to mold and mildew?

- Yes, fiberglass mat tissue is resistant to mold and mildew due to its non-porous and moisture-resistant properties.

- Q: What are the properties of fiberglass mat tissue?

- Fiberglass mat tissue, also known as fiberglass mat or fiberglass matting, is a type of non-woven material made from glass fibers. It possesses several properties that make it suitable for various applications. 1. Strength and durability: Fiberglass mat tissue is known for its high tensile strength, which means it can withstand significant amounts of stress without breaking. This property makes it ideal for reinforcing and strengthening different materials and structures. 2. Lightweight: Despite its strength, fiberglass mat tissue is relatively lightweight, making it easy to handle and transport. This property is particularly advantageous in industries where weight reduction is important, such as aerospace and automotive. 3. Flexibility: Fiberglass mat tissue is flexible, which allows it to conform to curved surfaces and complex shapes. This property makes it versatile and suitable for applications where the material needs to be molded or formed into specific designs. 4. Chemical resistance: Fiberglass mat tissue has excellent resistance to various chemicals, including acids, alkalis, and most solvents. This property makes it suitable for applications in corrosive environments, such as chemical processing plants or storage tanks. 5. Thermal insulation: Fiberglass mat tissue has good thermal insulation properties, meaning it can help to reduce heat transfer. This property makes it useful in applications where heat insulation is required, such as in the construction of walls, roofs, or insulation boards. 6. Fire resistance: Fiberglass mat tissue is inherently fire-resistant and does not contribute to the spread of flames. This property makes it widely used in applications where fire safety is essential, such as in the production of fire-resistant doors, panels, or insulation materials. 7. Sound insulation: Fiberglass mat tissue also offers good sound insulation properties, reducing noise transmission through walls or other structures. This property makes it suitable for use in soundproofing applications, such as in recording studios or automotive interior panels. Overall, the properties of fiberglass mat tissue make it a versatile material with a wide range of applications in various industries, including construction, automotive, aerospace, and marine. Its strength, flexibility, lightweight, chemical resistance, thermal and sound insulation properties, as well as its fire resistance, contribute to its popularity and usefulness in many different applications.

- Q: Does fiberglass mat tissue provide any thermal insulation?

- Yes, fiberglass mat tissue does provide thermal insulation. Fiberglass is a poor conductor of heat, which means it does not transfer heat easily. When used as a mat tissue, it helps to trap air within its fibers, creating a layer of insulation. This insulation layer acts as a barrier, preventing heat transfer through conduction and reducing thermal energy loss. Therefore, fiberglass mat tissue can be an effective solution for providing thermal insulation in various applications, such as construction, automotive, and aerospace industries.

- Q: What is the weight range of fiberglass mat tissue?

- The weight of fiberglass mat tissue can vary depending on the specific product and its intended application. Typically, the weight range of fiberglass mat tissue can be anywhere from approximately 20 grams per square meter (gsm) to over 100 gsm. Thinner and lighter fiberglass mat tissues are commonly employed for insulation purposes or as a reinforcing layer in composite materials. On the other hand, heavier fiberglass mat tissues are generally utilized for more demanding applications like roofing or flooring. It is worth noting that the weight range may also be influenced by factors such as the type of resin used, the desired strength or stiffness of the final product, and any specific requirements or specifications for a particular project.

- Q: Can fiberglass mat tissue be used for insulating ductwork?

- Indeed, insulating ductwork can be accomplished by employing fiberglass mat tissue. This insulation material is characterized by its composition of delicate glass fibers. Its lightweight and pliable nature facilitate effortless installation around ductwork, ensuring optimal thermal insulation. The outstanding insulating qualities of fiberglass mat tissue serve to minimize heat loss or gain within ducts, effectively enhancing energy efficiency. Additionally, it aids in condensation reduction and noise attenuation. Furthermore, its resistance to moisture, fire, and pests renders fiberglass mat tissue a fitting option for insulating ductwork in diverse environments.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Yes, fiberglass mat tissue is suitable for construction applications. It is commonly used as a reinforcement material in various construction projects due to its high strength, durability, and resistance to corrosion. It provides added structural integrity and stability to buildings, bridges, and other infrastructure. Additionally, fiberglass mat tissue is lightweight and easy to handle, making it a convenient choice for construction applications.

- Q: How does fiberglass mat tissue perform in terms of moisture vapor transmission?

- Fiberglass mat tissue performs poorly in terms of moisture vapor transmission due to its inherent non-permeable nature.

- Q: Can fiberglass mat tissue be used for automotive applications?

- Yes, fiberglass mat tissue can be used for automotive applications. Fiberglass mat tissue is a versatile material that is commonly used in the automotive industry for various purposes. It is often used as a reinforcement material in composite parts, such as bumpers, body panels, and interior components. The high strength and lightweight properties of fiberglass mat tissue make it an ideal choice for automotive applications, as it helps to enhance the overall performance and durability of the vehicle. Additionally, fiberglass mat tissue can also provide excellent sound insulation and vibration damping properties, which are crucial for improving the comfort and noise reduction in automobiles. Overall, fiberglass mat tissue is a reliable and widely used material in the automotive industry, contributing to the production of high-quality and efficient vehicles.

Send your message to us

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1300g 200~2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 200000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords