Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1080g 200 2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of FIBERGLASS SANDWICH FABRIC COMPLEX MAT Description:

It is the multi-layered combination mat .It consists of a PP core sandwiched between chopped glass fibers and stitch together, which is used for boat making. As usual, the area weight of PP core is 150g/m2 or 250g/m2 and area weight of chopped glass fibers is 300g/m2, 450g/m2 or 600g/m2.

Main Features of the FIBERGLASS SANDWICH FABRIC COMPLEX MAT

◎ This fabric is compatible with UP Resin, Vinyl ester resin, epoxy resin system etc. It is widely used in closed mould applications for vehicle bodies and panels, marine (boat hulls and decks), windmill nacelles, leisure vehicle and structural shapes.

◎ The structure of sandwich to increase strength, reduce product weight and better surface finish.

◎ low resin-consumption and faster wet-out.

◎ Good manufacturability and mechanical properties

◎ Improved fatigue and impact resistance

◎ Good drapability for complicated shapes and good resin flow

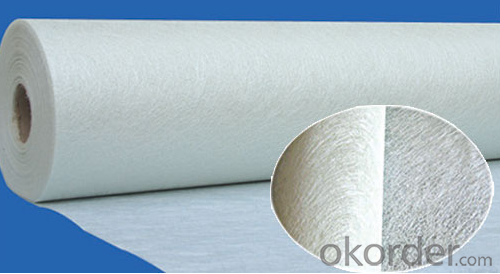

FIBERGLASS SANDWICH FABRIC COMPLEX MAT Images

FIBERGLASS SANDWICH FABRIC COMPLEX MAT Specification

| ||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Packing:

Each roll is wrapped by PE film and then packed into carton. Stacking in bulk or palletized is available; the pallet shall be no higher than 2 layers.

FAQ of FIBERGLASS SANDWICH FABRIC COMPLEX MAT

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Is fiberglass mat tissue suitable for underground applications?

- Yes, fiberglass mat tissue is suitable for underground applications. It is commonly used in underground construction projects due to its excellent strength, durability, and resistance to water and corrosion. Additionally, fiberglass mat tissue provides insulation and reinforcement, making it ideal for underground applications such as tunnels, basements, and pipelines.

- Q: Can fiberglass mat tissue be used for insulation in refrigeration systems?

- Yes, fiberglass mat tissue can be used for insulation in refrigeration systems. It is a commonly used material due to its excellent thermal insulation properties and ability to withstand low temperatures. It helps to reduce heat transfer and maintain the desired temperature inside the refrigeration system.

- Q: Can fiberglass mat tissue be used for bridge deck rehabilitation?

- Yes, fiberglass mat tissue can be used for bridge deck rehabilitation. It is a commonly used material due to its durability, strength, and resistance to corrosion. Additionally, it provides a smooth surface for the bridge deck, helps in preventing cracking and deterioration, and improves the overall structural integrity of the bridge.

- Q: Is fiberglass mat tissue resistant to fading?

- Fiberglass mat tissue is generally not resistant to fading. Fading occurs when a material loses its original color or brightness due to exposure to sunlight or other environmental factors. While fiberglass itself is known for its durability and resistance to weathering, the mat tissue used in fiberglass products is often susceptible to fading over time. This can be attributed to the binder or resin used to hold the fiberglass fibers together, as well as the pigments or dyes used to color the tissue. Exposure to UV rays and other outdoor elements can cause these components to break down and fade, resulting in a loss of color intensity or brightness. Therefore, if maintaining the aesthetic appearance of a fiberglass product is important, additional protective measures such as applying a UV-resistant coating or using pigments specifically designed for outdoor use may be necessary.

- Q: Can fiberglass mat tissue be used for making lightweight countertops?

- Indeed, lightweight countertops can be crafted using fiberglass mat tissue. This particular material, derived from delicate glass fibers, possesses the desirable qualities necessary for producing lightweight countertops. Not only does it offer robustness and longevity, but it is also pliable and can be effortlessly shaped and sized to fit various specifications. Moreover, fiberglass mat tissue possesses resistance to moisture, chemicals, and heat, rendering it a fitting choice for countertops that may encounter such elements. In conclusion, utilizing fiberglass mat tissue to fabricate lightweight countertops proves to be a pragmatic and effective resolution.

- Q: Is fiberglass mat tissue suitable for insulation in high-rise buildings?

- High-rise buildings can benefit from the suitability of fiberglass mat tissue for insulation. This widely used material possesses exceptional thermal and acoustic properties, making it an ideal choice. Its lightweight and flexible nature, along with easy installation, ensure efficiency and effectiveness in high-rise structures. Furthermore, fiberglass mat tissue boasts excellent fire resistance, a crucial requirement for multi-story buildings. It also resists moisture, mold, and pests, ensuring durability and optimal performance. Customization for walls, floors, and ceilings allows consistent insulation throughout the entire building. In conclusion, fiberglass mat tissue is a dependable and cost-effective insulation solution for high-rise buildings.

- Q: What is the flexibility of fiberglass mat tissue?

- The flexibility of fiberglass mat tissue is high, as it can easily bend and conform to different shapes and surfaces without breaking or losing its structural integrity.

- Q: Can fiberglass mat tissue be used for making electrical enclosures?

- No, fiberglass mat tissue is not suitable for making electrical enclosures. Electrical enclosures require materials that have good electrical insulation properties to prevent electrical shocks and short circuits. Fiberglass mat tissue is primarily used for reinforcement in composites and does not possess the necessary electrical insulation properties. Materials such as plastics, polymers, or metals with appropriate electrical insulation characteristics should be used for making electrical enclosures.

- Q: Can fiberglass mat tissue be used in automotive manufacturing?

- Yes, fiberglass mat tissue can be used in automotive manufacturing. Fiberglass mat tissue is a lightweight, flexible material made from glass fibers that are bonded together with a binder. It is commonly used in the automotive industry for various applications such as reinforcing body panels, creating structural components, and improving sound and heat insulation. One of the main advantages of using fiberglass mat tissue in automotive manufacturing is its high strength-to-weight ratio. It provides excellent reinforcement properties while adding minimal weight to the vehicle, making it an ideal choice for achieving fuel efficiency and reducing emissions. Additionally, fiberglass mat tissue is highly moldable, allowing it to be easily shaped and formed into complex geometries required for automotive parts. This material can be used to reinforce areas that are susceptible to high stress, such as the roof, doors, and undercarriage, thereby enhancing the overall strength and durability of the vehicle. Moreover, fiberglass mat tissue offers excellent resistance to corrosion, chemicals, and extreme temperatures, making it suitable for use in diverse automotive environments. It is also an effective sound and heat insulator, helping to reduce noise and maintain a comfortable interior temperature. Overall, fiberglass mat tissue has proven to be a valuable material in automotive manufacturing due to its lightweight, strong, moldable, and durable properties. Its versatility and performance characteristics make it a preferred choice for many automotive manufacturers looking to enhance the quality and performance of their vehicles.

- Q: What is the flexural strength of fiberglass mat tissue?

- The flexural strength of fiberglass mat tissue refers to its ability to resist bending or flexing without breaking. It is typically high due to the reinforcing properties of the fiberglass material, making it suitable for applications requiring structural integrity and resistance to deformation.

Send your message to us

Fiberglass Mat Tissue Sandwich Fabric Complex Mat 1080g 200 2600 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords