Fiberglass Fabrics Reinforced Fiberglass Roofing Panels (Sheets) for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Fiberglass Roofing Panels(Sheets) for Constructin Using

Description

In general, our company specializes in FRP grating, FRP decking, FRP platform and other products of FRP. We have a varity of FRP products sold over the country because we have our own teams of design, manufacturing and sales with hundreds of staffs.

At the same time, we are devoted to creating a production and marketing for FRP products, which has certain influence in China by proceeding with professional teams, rigorous quality management system and advanced production facility.

Today, we’re planning to win more market shares in the world and let more customers know us.

Photos

Product Traits

1. The intensity and stiffness is quite prominent,.

2. Lightweight, high strength pultrusion process molding FRP profiles have high glass fiber content (60%). In this situation, the density of glass fiber reinforced plastic is only about a quarter of the steel.

3. Corrosion resistance no rust, no maintenance, long service life.

4. Anti-fatigue high anti- fatigue strength, allowing repeated bending without permanent deformation.

5. Anti-aging select highquality FRP pultrusion profiles, the service life of the product can be more than 20 years.

6. Anti-UV agent are added into all pultrusion FRP profiles get the best anti-uv effect.

Product Advantage

Coated with prevent aging layer

Excellent insulating performance

- High strength.

Easy to maintain.

Long service life.

Easy to install.

Good light transmittance.

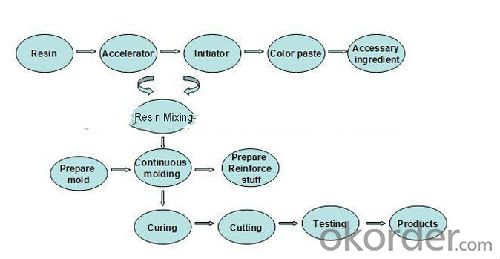

Production Process

Specification&Technical Parameters

Mechanical properties: high rigidity lighting panels

Plate matches: match with general prepainted galvanized sheet, galvanized steel

Resin composites: Improved anti-aging SMR198 resin

Fiber reinforcement: E-glass fiber untwisted without glue

Surface treatment: affixing MELINEX301 film

Stiffener line: surface with longitudinal uniform distribution of anti-LAC gluten

Glass fiber: not less than 28%

Unit Weight: 1800g / ㎡, 2400g / ㎡, 3050g / ㎡

Nominal thickness: 1.2 mm, 1.5mm, 2.0mm (tolerance ≤ 10%)

Temperature limits: -60 ℃ ~ +130 ℃

Transmittance (1.5mm): 72% ± 2% (fog white, sky blue, water green), 52% ± 2% (white porcelain)

UV-rate: 99%

Tensile strength: 90Mpa

Flexural strength: 160 Mpa

Elongation: 1.9%

Pap hardness: ≥ 50

Thermal expansion coefficient: 1.5 ~ 3.2 * 10-5 / K

Thermal conductivity: K = 0.23W / m * K

Guarantee: 15 years

NOTE: In special cases, the surface film varieties vary according to needs, such as Melinex389, PT055 and so on.

FAQ

1.Which country do you mainly export to?

A: Our products are very popular in Mid East, India, South East Asia, Latin America, Africa.

2.Q: Would you like to let us get your sampels?

A: Yes, of course. We will send you samples for your confirmation before you place firm orders.

- Q: What are the different thicknesses of fiberglass fabric available?

- Fiberglass fabric is available in a variety of thicknesses to suit different applications and requirements. The thickness of fiberglass fabric is typically measured in ounces per square yard (oz/yd^2). The most common thicknesses of fiberglass fabric range from 4 oz/yd^2 to 10 oz/yd^2, with increments of 2 oz/yd^2. 4 oz/yd^2 fiberglass fabric is relatively lightweight and is commonly used in applications where a thin and flexible material is needed, such as for repairs on small boats or automotive parts. 6 oz/yd^2 fiberglass fabric is a medium-weight option that provides better strength and durability compared to 4 oz/yd^2. It is often used for general repairs, reinforcing weak areas, or creating lightweight structures. 8 oz/yd^2 fiberglass fabric is a heavier option that offers increased strength and rigidity. It is commonly used for more demanding applications, such as reinforcing large structural components or creating composite parts. 10 oz/yd^2 fiberglass fabric is the thickest commonly available option and is used when maximum strength and durability are required. It is often used for industrial applications, such as reinforcing concrete structures or manufacturing high-performance composite materials. In addition to these common thicknesses, there are also specialty fiberglass fabrics that can be much thicker or thinner depending on the specific application. It is important to select the appropriate thickness of fiberglass fabric based on the intended use to ensure optimal performance and desired results.

- Q: What are the different fiberglass fabric finishes for abrasion resistance?

- There are several different fiberglass fabric finishes that enhance abrasion resistance, including silicone, PTFE (Teflon), acrylic, and neoprene. Each of these finishes provides varying levels of protection against wear and tear, making fiberglass fabrics suitable for a wide range of applications requiring durability and longevity.

- Q: Can fiberglass fabric be used for gaskets and seals?

- Yes, fiberglass fabric can be used for gaskets and seals. It is a versatile material that offers high temperature resistance, chemical resistance, and durability, making it suitable for various sealing applications. Additionally, fiberglass fabric can be easily molded and cut to fit specific shapes and sizes, providing an effective barrier against leaks and ensuring a tight seal.

- Q: What are the different lamination options available for fiberglass fabric?

- There are several lamination options available for fiberglass fabric, depending on the specific requirements and applications. Some of the common lamination options include: 1. Polyester Resin Lamination: This is the most commonly used lamination option for fiberglass fabric. Polyester resin is applied to the fabric, forming a strong and durable bond. It provides good chemical resistance and is suitable for applications where high strength is required. 2. Epoxy Resin Lamination: Epoxy resin lamination offers superior strength and excellent adhesion. It is often used in applications that require high-performance and resistance to harsh environmental conditions. Epoxy resin also provides good chemical and heat resistance. 3. Polyurethane Lamination: Polyurethane lamination offers flexibility and excellent abrasion resistance. It is commonly used in applications that require fabric flexibility and durability, such as inflatable structures or protective clothing. 4. Vinyl Ester Resin Lamination: Vinyl ester resin is a hybrid between polyester and epoxy resins, offering high strength and excellent corrosion resistance. It is commonly used in applications exposed to harsh chemicals or environments, such as chemical storage tanks or marine applications. 5. Thermoplastic Lamination: Thermoplastic lamination involves the use of heat and pressure to bond a thermoplastic film onto the fiberglass fabric. This option provides good chemical resistance and is often used in applications that require waterproofing or resistance to environmental elements. It is important to consider the specific requirements and intended use of the fiberglass fabric when choosing the appropriate lamination option. Factors such as strength, flexibility, chemical resistance, and environmental conditions will help determine the most suitable lamination choice.

- Q: How does fiberglass fabric perform in terms of sound absorption?

- Fiberglass fabric is widely recognized for its excellent sound absorption properties. Due to its unique composition and structure, fiberglass fabric effectively absorbs sound waves, reducing echoes and reverberations in a given space. The fabric's density and porous nature allow it to trap and dissipate sound energy, preventing it from bouncing back into the room. This makes fiberglass fabric a popular choice for soundproofing applications in various industries, including recording studios, theaters, and commercial buildings. Additionally, fiberglass fabric can be used in wall panels, acoustic curtains, and other sound-absorbing products to enhance the overall acoustic performance of a space. Overall, fiberglass fabric is highly regarded for its ability to absorb sound, contributing to improved sound quality and reduced noise levels in a given environment.

- Q: What are the characteristics of glass fiber acoustic panels?

- Have a good shape, small volume density, thermal conductivity, both thermal insulation, sound-absorbing performance, corrosion resistance, chemical stability. Glass fiber sound-absorbing panels, referred to as glass wool or sound insulation cotton, glass wool is a category of glass fiber, is a man-made inorganic fiber. Glass wool is the melting of glass fiber, forming a cotton like material, the chemical composition of the glass, is an inorganic fiber.

- Q: Is fiberglass fabric suitable for making tents and awnings?

- Yes, fiberglass fabric is suitable for making tents and awnings. It is lightweight, durable, and offers excellent resistance to extreme weather conditions such as rain, wind, and UV rays. Additionally, fiberglass fabric is known for its strong tensile strength and fire resistance, making it a reliable choice for outdoor applications.

- Q: How is fiberglass fabric cut?

- Fiberglass fabric can be cut using a variety of methods, depending on the desired outcome and the tools available. One common method is using scissors or a rotary cutter, which can be effective for straight cuts and smaller pieces. However, for more intricate or precise cuts, a hot knife or a laser cutter may be preferred. A hot knife heats up as it cuts through the fiberglass fabric, which helps to seal the edges and prevent fraying. This method is especially useful when working with thicker or heavier fiberglass materials. Laser cutters, on the other hand, use a focused beam of light to melt through the fabric, resulting in clean and precise cuts. This method is often used in industrial settings where high accuracy and efficiency are required. Regardless of the cutting method used, it is important to wear appropriate safety equipment, such as gloves and goggles, as fiberglass can be irritating to the skin and eyes. Additionally, it is advisable to work in a well-ventilated area to minimize exposure to fiberglass dust particles.

- Q: Can fiberglass fabric be used for making soundproofing materials?

- Yes, fiberglass fabric can be used for making soundproofing materials. Its dense and fibrous composition helps absorb sound waves, reducing noise transmission and enhancing sound insulation capabilities.

- Q: Can fiberglass fabrics be used for outdoor applications?

- Absolutely! Outdoor applications are perfect for fiberglass fabrics. The durability and ability to withstand harsh weather conditions are what make fiberglass an ideal material for outdoor use. It is commonly seen in outdoor furniture, awnings, canopies, and covers. Moreover, fiberglass fabrics are highly resistant to UV rays, moisture, and mildew, ensuring that they retain their strength and appearance when exposed to the elements. Additionally, their lightweight and flexible nature make fiberglass fabrics a breeze to install and work with for any outdoor project.

Send your message to us

Fiberglass Fabrics Reinforced Fiberglass Roofing Panels (Sheets) for Construction Use

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords