Fiberglass Mat Tissue Multiaxial Fabric-UD Series (0° or 90°)

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Multiaxial Fabric-UDDescription:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of theFiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

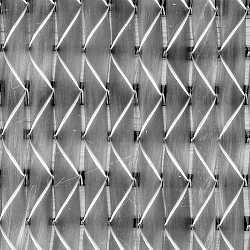

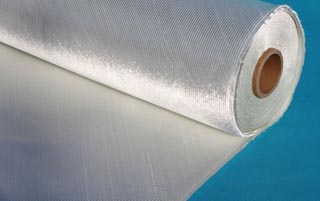

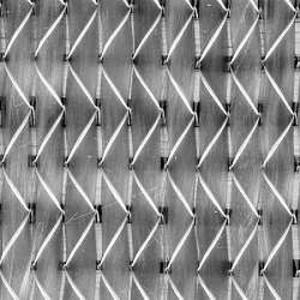

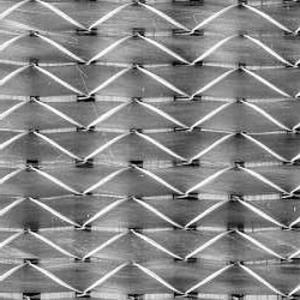

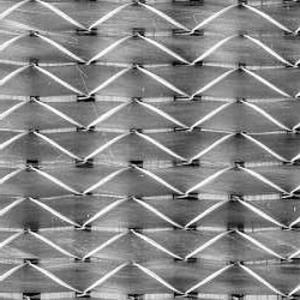

Unidirectional Fiberglass Multiaxial Fabric-UD Images:

Fiberglass Multiaxial Fabric-UD Specification:

Code | Total weight g/m2 | Weight of each layer, g/m2 | Width mm | ||||

0° | 90° | +45° | -45° | Chopping | |||

E-L300 | 350 | 300 | 50 | 200~2600 | |||

E-L350 | 400 | 350 | 50 | 200~2600 | |||

E-L400 | 450 | 400 | 50 | 200~2600 | |||

E-L450 | 500 | 450 | 50 | 200~2600 | |||

E-L500 | 550 | 500 | 50 | 200~2600 | |||

E-L600 | 650 | 600 | 50 | 200~2600 | |||

E-L650 | 700 | 650 | 50 | 200~2600 | |||

E-L900 | 930 | 880 | 50 | 200~2600 | |||

E-L700/200 | 950 | 700 | 50 | 200 | 200~2600 | ||

E-T200 | 200 | 200 | 200~2600 | ||||

E-T450 | 450 | 450 | 200~2600 | ||||

E-T500 | 500 | 500 | 200~2600 | ||||

E-TM300/300 | 600 | 300 | 300 | 200~2600 | |||

E-TM600/450 | 1050 | 600 | 450 | 200~2600 | |||

E-LM750/200 | 950 | 750 | 200 | 200~2600 | |||

FAQ of Fiberglass Multiaxial Fabric-UD:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: Does fiberglass mat tissue require any special handling precautions?

- Yes, fiberglass mat tissue does require special handling precautions. Due to its nature, fiberglass mat tissue can release tiny glass fibers into the air when handled incorrectly. These fibers can cause skin irritation, eye irritation, and respiratory issues if inhaled. Therefore, it is important to wear appropriate protective clothing, such as gloves, long-sleeved shirts, pants, and safety goggles, when handling fiberglass mat tissue. It is also advisable to work in a well-ventilated area or use respiratory protection if working in a confined space. Additionally, it is crucial to handle the material gently to avoid any breakage or damage that could release more fibers into the environment. Proper disposal methods should also be followed to prevent any potential harm. Overall, taking these precautions ensures the safety and well-being of individuals handling fiberglass mat tissue.

- Q: What is the thermal conductivity of fiberglass mat tissue?

- The thermal conductivity of fiberglass mat tissue is typically low, ranging from 0.03 to 0.05 W/m·K. This means that fiberglass mat tissue is a good insulator and can effectively resist the transfer of heat. Its low thermal conductivity makes it suitable for applications such as thermal insulation in buildings, industrial equipment, and appliances.

- Q: Is fiberglass mat tissue suitable for chemical storage tanks?

- Chemical storage tanks often find fiberglass mat tissue to be a suitable choice. The chemical resistance properties of fiberglass itself are well-known, which is why it is commonly used for storing a wide variety of chemicals. Moreover, fiberglass mat tissue is typically employed as a reinforcement layer during the construction of fiberglass tanks, providing them with added strength and durability. Nevertheless, it is important to consider the specific chemical being stored. Certain highly corrosive or reactive chemicals may necessitate the use of more specialized materials or additional protective coatings to ensure the tank's integrity. Therefore, it is always advisable to seek guidance from a professional engineer or manufacturer in order to identify the most appropriate materials for a given chemical storage application.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Yes, fiberglass mat tissue typically provides some level of UV resistance. The fiberglass mat tissue is made up of glass fibers that are embedded in a matrix of resin. These fibers and resin provide some degree of protection against UV radiation from the sun. However, it is important to note that the level of UV resistance may vary depending on the specific composition and manufacturing process of the fiberglass mat tissue. Additionally, prolonged exposure to UV radiation can still cause some degradation over time, so it is recommended to take appropriate measures such as using UV-resistant coatings or finishes to enhance the durability and lifespan of the fiberglass mat tissue in outdoor applications.

- Q: Is fiberglass mat tissue compatible with vacuum infusion processes?

- Yes, fiberglass mat tissue is compatible with vacuum infusion processes. Fiberglass mat tissue is often used as a reinforcement material in composite manufacturing processes, including vacuum infusion. The vacuum infusion process involves the use of a vacuum to remove air and ensure complete resin impregnation of the fiberglass mat tissue. The porous nature of the fiberglass mat tissue allows the resin to flow through and saturate the fibers, resulting in a strong and durable composite part. This makes fiberglass mat tissue an ideal choice for vacuum infusion processes.

- Q: Does anyone know the hardness value of the heat conductive gasket? Does it contain the hardness of the carrier (glass fiber)?

- SHORE hardness is only for the hardness of the heat conductive gasket itself

- Q: What is the flexural strength of fiberglass mat tissue?

- The flexural strength of fiberglass mat tissue refers to its ability to resist bending or flexing without breaking. It is typically high due to the reinforcing properties of the fiberglass material, making it suitable for applications requiring structural integrity and resistance to deformation.

- Q: How is fiberglass mat tissue bonded to surfaces?

- Adhesive materials are commonly utilized to bond fiberglass mat tissue to surfaces. To initiate the bonding process, the adhesive is applied onto the surface where the fiberglass mat tissue will be attached. Typically, a two-part epoxy resin or a specialized fiberglass adhesive, specifically formulated for bonding fiberglass materials, is used. Following the manufacturer's instructions, the adhesive is thoroughly mixed and then evenly spread onto the surface using a brush, roller, or trowel. With utmost care, the fiberglass mat tissue is then placed onto the adhesive-covered surface and firmly pressed down to ensure optimal adhesion. Subsequently, the adhesive is left to cure for the recommended duration, allowing it to solidify and establish a robust bond between the fiberglass mat tissue and the surface. This bonding technique guarantees the secure attachment of the fiberglass mat tissue to the surface, offering reinforcement, protection, or other desired attributes based on the specific application.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can typically withstand is around 600-700 degrees Celsius.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose potential health and safety concerns. The fine fiberglass particles present in the air during handling and cutting can be inhaled, leading to respiratory issues such as irritation, coughing, and difficulty breathing. Prolonged exposure to these particles may also result in long-term lung damage. Additionally, direct skin contact with the fiberglass can cause skin irritation and allergic reactions. Hence, it is important to use appropriate personal protective equipment, such as gloves, masks, and goggles, to minimize these risks and ensure a safe working environment.

Send your message to us

Fiberglass Mat Tissue Multiaxial Fabric-UD Series (0° or 90°)

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords