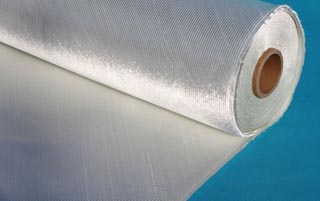

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 350gsm/50gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

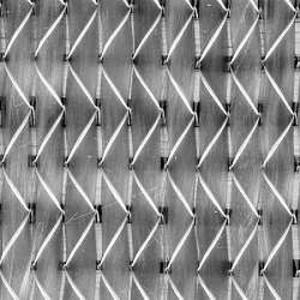

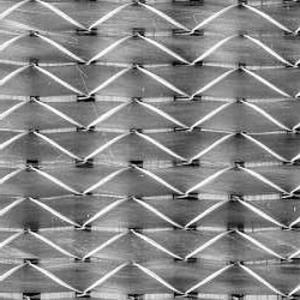

This fabric is made of fiberglass roving which are aligned at 0° or 90° into one layer of roving by stitching together with or without one layer of chopped strand. It is mainly applied in the hand lay up, RTM and other close molding processes. | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

Product Feature | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

FAQ

Packaging: | |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||

- Q: How does the fiber distribution of fiberglass mat tissue affect its strength?

- The strength of fiberglass mat tissue is significantly influenced by the distribution of its fibers. The primary source of strength for fiberglass mat tissue is the inclusion of fibers within the material. These fibers act as reinforcement and aid in evenly distributing stress and load across the surface. The distribution of fibers in fiberglass mat tissue refers to their arrangement and orientation within the material. When fibers are evenly distributed, with a consistent arrangement and orientation, the strength of the fiberglass mat tissue is enhanced. This uniform distribution allows for efficient transfer of load from one fiber to another, resulting in improved overall strength. Conversely, an uneven or random distribution of fibers, where they are clumped together or oriented in various directions, compromises the strength of the fiberglass mat tissue. This uneven distribution can create areas of concentrated stress, leading to weak points and potential failure under load. Additionally, the strength of fiberglass mat tissue is also influenced by the length and density of the fibers. Longer fibers provide greater reinforcement and enhance the tensile strength of the material. Furthermore, a higher fiber density, meaning more fibers per unit area, increases the overall strength and performance of the fiberglass mat tissue. In conclusion, the strength of fiberglass mat tissue is directly impacted by the distribution of its fibers. A uniform and evenly distributed arrangement of fibers improves the material's strength by facilitating efficient load transfer. Conversely, an uneven or random distribution compromises the strength by creating stress concentrations and weak points. The fiber length and density also contribute to the overall strength of the fiberglass mat tissue.

- Q: Is fiberglass mat tissue fire-resistant?

- Fiberglass mat tissue is not naturally fire-resistant, contrary to popular belief. Although fiberglass itself is non-combustible, manufacturers usually mix the mat tissue with a flammable binder or resin. Nevertheless, there are specialized fiberglass mat tissue options that have undergone treatment with fire-resistant coatings or additives. These treated materials offer enhanced fire resistance properties and are frequently utilized in construction and insulation materials that prioritize fire safety. It is crucial to carefully examine the product specifications or seek advice from the manufacturer to ascertain the fire resistance capabilities of a specific fiberglass mat tissue.

- Q: What is the typical width of fiberglass mat tissue rolls?

- The typical width of fiberglass mat tissue rolls can vary depending on the specific manufacturer and intended application. However, in the construction and insulation industries, fiberglass mat tissue rolls are commonly available in widths ranging from 1.22 meters (4 feet) to 2.44 meters (8 feet). These dimensions are often chosen to align with standard building materials and construction practices. It is important to note that there may be variations in width options depending on the region or supplier, so it is advisable to consult with the manufacturer or supplier for the specific width requirements for a particular project.

- Q: How is fiberglass mat tissue used in the construction industry?

- Fiberglass mat tissue is commonly used in the construction industry as a reinforcement material. It is applied to various surfaces, such as walls, roofs, and flooring, to enhance their strength and durability. The fiberglass mat tissue is often embedded in resin or other binding agents to form a composite material that can withstand heavy loads and resist cracks. Its widespread use in construction helps to increase the structural integrity of buildings and ensures long-lasting performance.

- Q: Does fiberglass mat tissue provide any UV resistance?

- Indeed, some degree of UV resistance is typically offered by fiberglass mat tissue. Comprised of glass fibers embedded in a resin matrix, this material provides a certain level of safeguard against UV radiation emitted by the sun. Nevertheless, it should be emphasized that the extent of UV resistance may differ based on the precise composition and manufacturing procedure of the fiberglass mat tissue. Furthermore, extended exposure to UV radiation can still result in gradual deterioration. Therefore, it is advisable to implement suitable measures, such as employing UV-resistant coatings or finishes, to augment the longevity and resilience of fiberglass mat tissue when utilized outdoors.

- Q: What is the moisture absorption rate of fiberglass mat tissue?

- The moisture absorption rate of fiberglass mat tissue is relatively low, as fiberglass is known for its water-resistant properties.

- Q: Does fiberglass mat tissue have any fire-resistant properties?

- Fiberglass mat tissue indeed possesses fire-resistant properties. Its composition of glass fibers and a thermosetting resin inherently grants it fire resistance. When subjected to high temperatures or flames, fiberglass mat tissue resists ignition and combustion, instead hindering flame propagation and aiding fire containment. As a result, fiberglass mat tissue proves suitable for fire protection necessities in various applications, including insulation, fire barriers, and fireproof panels. Nevertheless, it is crucial to acknowledge that although fiberglass exhibits fire resistance, it remains susceptible to melting or burning in extreme circumstances.

- Q: Can fiberglass mat tissue be used for making lightweight automotive parts?

- Yes, fiberglass mat tissue can be used for making lightweight automotive parts.

- Q: Can fiberglass mat tissue be used for repairing fiberglass fenders?

- Fiberglass fenders can be repaired using fiberglass mat tissue. This versatile material is commonly employed in fiberglass repair tasks, serving as a reinforcement layer to enhance strength and durability in the repaired region. To mend damaged or cracked areas of fiberglass fenders, one can apply a resin layer and then lay the fiberglass mat tissue on top. By saturating the mat tissue with additional resin, a strong bond is formed, ensuring a smooth finish. This restorative process not only revitalizes the fender's structural integrity but also delivers a seamless repair. It is worth noting, however, that the extent of the damage and the expertise of the repairer ultimately determine the success of the repair.

- Q: Can fiberglass mat tissue be used for making boat hulls?

- Fiberglass mat tissue is indeed suitable for the construction of boat hulls. This lightweight and robust material is widely employed in the boat-building and repairing industry. By combining fiberglass strands with a binder, a flexible mat is formed, allowing for easy shaping and molding into various forms. Boat hulls necessitate a sturdy, water-resistant material with excellent structural integrity, all of which fiberglass mat tissue offers. Moreover, this material is relatively easy to manipulate and can be layered to enhance its strength according to requirements. Consequently, it is a favored option for constructing boat hulls.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD Series 350gsm/50gsm

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 kg

- Supply Capability:

- 100000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords