Fiberglass Mat Tissue Reinforced Aluminum Foil Mesh Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Petrochemical industry -- heat insulation and sound absorption of equipments for petroleum industry, power industry and chemical industry.

Construction industry -- heat insulation and sound absorption of partition, curtain wall, roofs and fences for construction.

Mining industry -- heat preservation and fireproof for industrial kiln, oven, large-caliber storage tank and shipping.

2.Main features of Glass Wool Blanket:

1. Small coefficient of heat conductivity and good capability of heating preservation

2. Outstanding effect of energy-saving.

3. Excellent fireproof capability. Excellent sound absorption and sound insulation capability.

4. Green building materials and no harm for body.

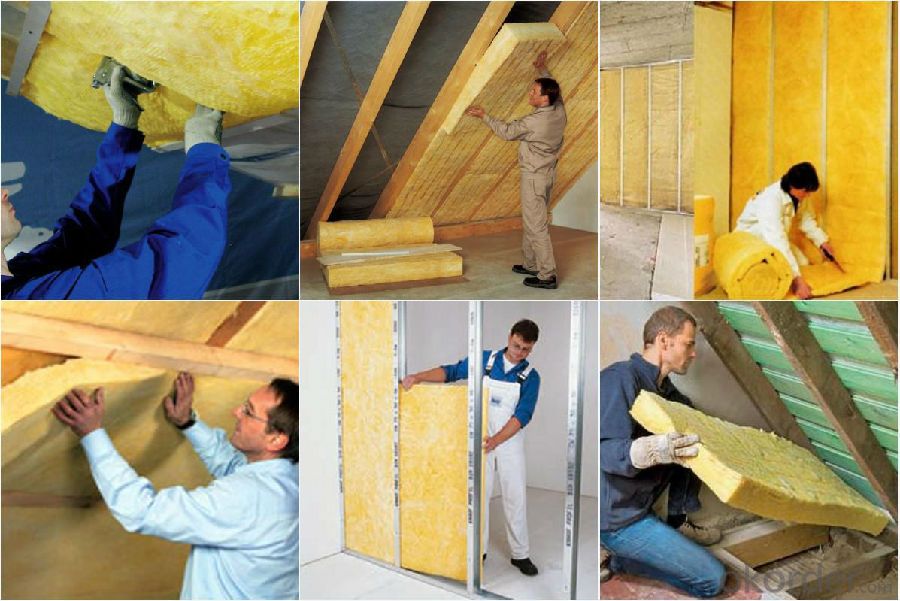

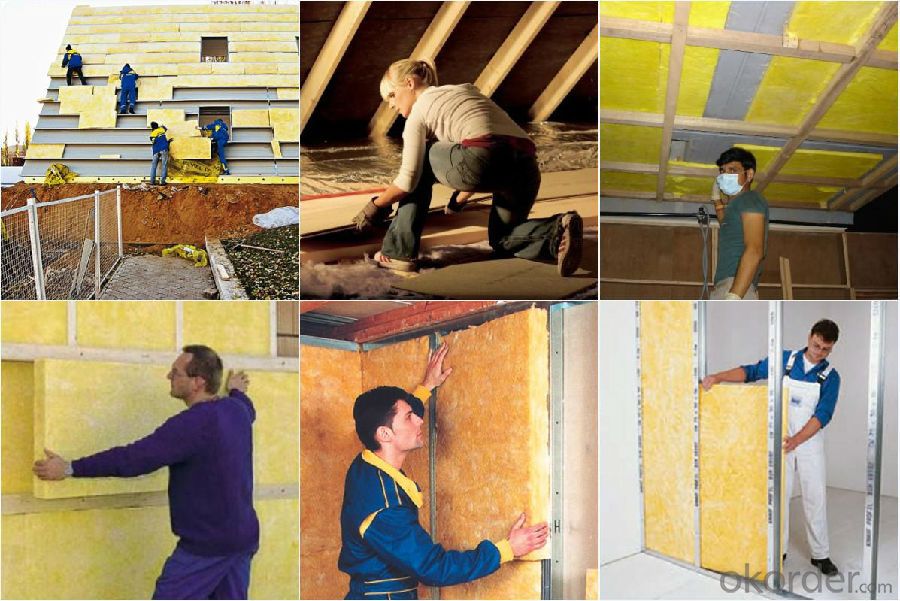

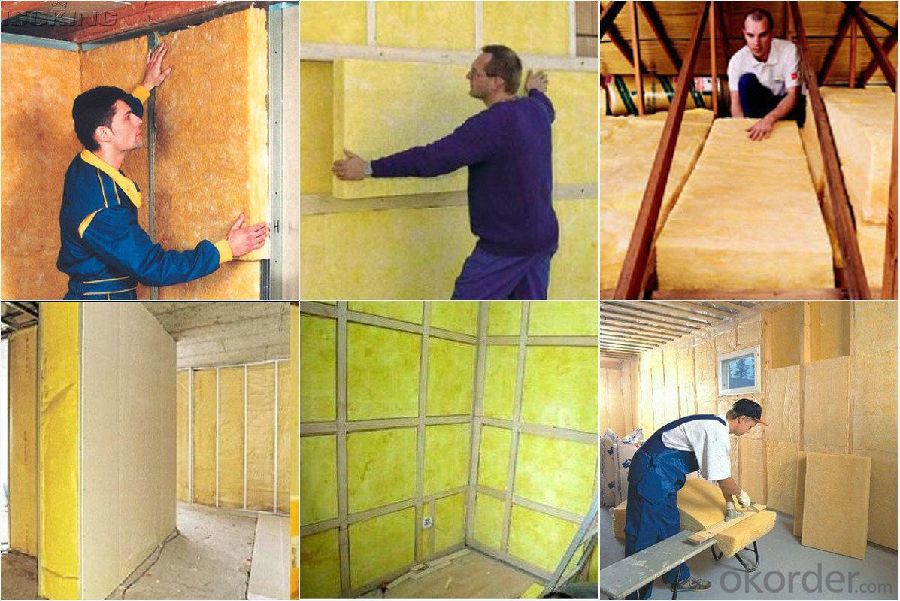

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How does fiberglass mat tissue perform in terms of air permeability?

- Fiberglass mat tissue is characterized by its low air permeability. Its tight weave and construction, using fiberglass strands, result in less porosity, thereby allowing minimal airflow. This quality renders fiberglass mat tissue appropriate for situations that require minimal air permeability, such as insulation or filtration systems. By limiting the flow of air, fiberglass mat tissue enhances thermal insulation and enhances filtration efficiency.

- Q: What is the impact resistance of fiberglass mat tissue?

- The impact resistance of fiberglass mat tissue is quite high due to its inherent properties and construction. Fiberglass mat tissue is composed of fine glass fibers that are randomly arranged and bonded together with a binder material. This arrangement creates a strong and flexible mat that can withstand impacts and external forces. The random orientation of the glass fibers allows for the distribution of stress and energy across the entire mat tissue. When an impact is applied, the fibers absorb and disperse the force, preventing it from being concentrated in one area. This property helps to minimize the risk of cracks, fractures, or failures in the material. Additionally, the binder material used in fiberglass mat tissue provides further reinforcement and cohesion to the structure. It acts as a bonding agent, keeping the glass fibers in place and enhancing their overall strength. This bonding ensures that the mat tissue remains intact and resilient even under high impact loads. Due to its excellent impact resistance, fiberglass mat tissue is commonly used in various applications where durability and strength are essential. It is often utilized in the manufacturing of composite materials, such as fiberglass-reinforced plastics (FRP), to enhance their impact resistance and structural integrity. It is also frequently employed in the construction industry for applications like roofing, wall insulation, and soundproofing, where it provides protection against impacts and external forces. Overall, the impact resistance of fiberglass mat tissue is a key characteristic that contributes to its widespread use in numerous industries. Its ability to withstand impacts and distribute forces makes it a reliable material for applications that require strength, durability, and protection against external forces.

- Q: How is fiberglass mat tissue used in the production of agricultural equipment?

- Fiberglass mat tissue, a thin fiberglass material, plays a vital role in agricultural equipment production. It is mainly used as a reinforcement material during the manufacturing process of agricultural machinery like tractors, harvesters, and sprayers. One significant use of fiberglass mat tissue in agricultural equipment production is constructing structural components. The tissue reinforces body panels and chassis, providing strength and durability to the machinery. This reinforcement enhances the overall structural integrity and load-bearing capacity of the equipment, making it more reliable and capable of withstanding harsh conditions. Furthermore, fiberglass mat tissue is employed in agricultural equipment production due to its corrosion resistance properties. Agricultural machinery is often exposed to chemicals, fertilizers, and the elements. By incorporating fiberglass mat tissue in the manufacturing process, the machinery becomes more resistant to corrosion. This increases its lifespan and reduces maintenance costs. In addition, fiberglass mat tissue is utilized to enhance insulation and soundproofing capabilities in agricultural equipment. By adding layers of the tissue between panels and components, the machinery becomes better insulated against temperature fluctuations, reducing energy loss and improving efficiency. Moreover, the tissue helps dampen noise and vibration, creating a quieter and more comfortable working environment for operators. To summarize, fiberglass mat tissue is a vital component in agricultural equipment production. Its reinforcement, corrosion resistance, insulation, and soundproofing properties contribute to the overall performance, durability, and efficiency of agricultural machinery, making it an indispensable material in this industry.

- Q: Is fiberglass mat tissue resistant to mold growth?

- Yes, fiberglass mat tissue is resistant to mold growth.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. It provides excellent thermal insulation properties and is fire-resistant, which is crucial for ensuring the safety of patients and staff in healthcare environments. Additionally, fiberglass mat tissue is a durable and cost-effective option for insulation, making it a practical choice for hospitals.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Yes, fiberglass mat tissue can be used for pipe wrapping. Fiberglass mat tissue is a lightweight and flexible material that is commonly used for reinforcing and protecting various structures, including pipes. It is designed to provide strength and durability to the pipes, making them more resistant to damage and corrosion. The fiberglass mat tissue can be easily wrapped around the pipe, creating a protective layer that helps to prevent leaks and extend the lifespan of the pipe. Additionally, fiberglass mat tissue is also known for its excellent insulation properties, which can help to maintain the temperature of the contents flowing through the pipe. Overall, fiberglass mat tissue is a suitable material for pipe wrapping and is commonly used in various industries for this purpose.

- Q: Can fiberglass mat tissue be used in high-temperature applications?

- Unfortunately, high-temperature applications do not permit the usage of fiberglass mat tissue.

- Q: Is fiberglass mat tissue suitable for insulation in sports facilities?

- Yes, fiberglass mat tissue is suitable for insulation in sports facilities. It is a commonly used material for insulation due to its excellent thermal insulation properties, durability, and resistance to moisture. Additionally, fiberglass mat tissue is lightweight and easy to install, making it a practical choice for sports facilities where energy efficiency and temperature control are important factors.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not typically used for making furniture. Fiberglass mat tissue is a lightweight material that is commonly used in industries such as construction, automotive, and aerospace for its strength and durability. It is often used as a reinforcement material in the production of composite materials, such as fiberglass-reinforced plastic (FRP) or fiberglass-reinforced polymers (FRPs). While fiberglass may offer some advantages in terms of strength and resistance to moisture, it is not a commonly used material in furniture manufacturing. Furniture typically requires materials that are aesthetically pleasing, comfortable, and easy to work with. Fiberglass can be difficult to shape, may not provide the desired texture or visual appeal, and can be uncomfortable to sit or lie on. Instead, furniture manufacturers typically utilize materials such as wood, metal, plastic, upholstery fabrics, and foam for creating furniture pieces. These materials offer a wider range of options in terms of design, comfort, and customization, making them more suitable for furniture production.

- Q: How does the thickness of fiberglass mat tissue affect its performance?

- The thickness of fiberglass mat tissue directly affects its performance. A thicker tissue provides increased strength, durability, and insulation properties. It also enhances the material's ability to absorb impact and resist damage. Thinner tissues, on the other hand, offer greater flexibility and easier handling. Therefore, choosing the appropriate thickness of fiberglass mat tissue is crucial to achieve desired performance characteristics in various applications.

Send your message to us

Fiberglass Mat Tissue Reinforced Aluminum Foil Mesh Glass Wool Insulation

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords