Fiberglass Mat Tissue Coated Aluminum Foil Heat Insulation Glass Wool Felt

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Blanket:

Glass wool, which belongs to glass fiber , is a kind of man-made inorganic fiber. It is made from fibrosis glass melt in wool shape, which belongs to inorganic fiber and fiber in its chemical ingredient. Its merit is better in shape, low density and volume, low in thermal conduction, better heat preservation and thermal insulation, fine sound absorption, corrosion-resistant and stable chemical property.

Glass Wool Blanket complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

• Unique technology; rebound degree after compressive packing is up to 99.2%.

• Soft and long glass fibers can maximally lessen flying catkins in the construction.

• Sound absorption and noise reduction; it can effectively prevent sound from spreading.

• Grade A1 incombustible materials.

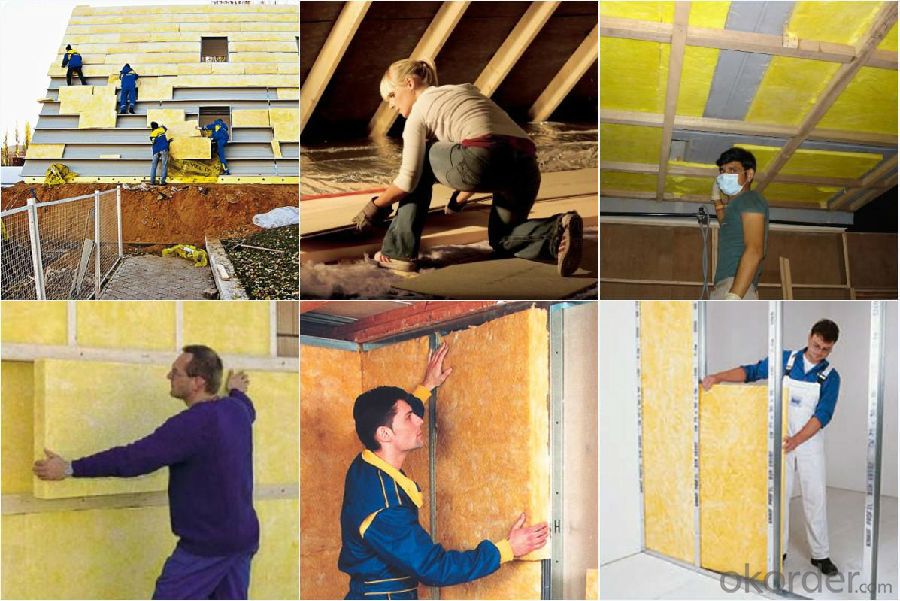

• Easy for construction; cutting at will.

• Antisepsis, ageing resistance, and anticorrosion, ensuring a healthy environment.

• Low moisture absorption; stable physical properties.

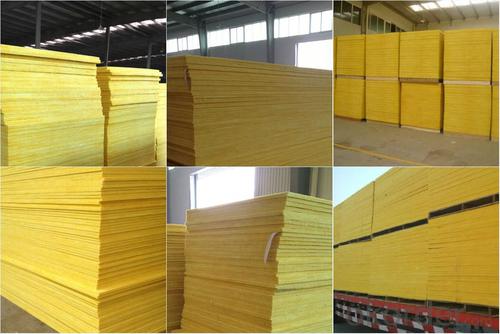

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How long does fiberglass mat tissue last?

- The lifespan of fiberglass mat tissue varies depending on various factors such as the quality of the material, environmental conditions, and maintenance. However, on average, fiberglass mat tissue can last for several decades if properly installed and cared for.

- Q: What is fiberglass mat tissue?

- Fiberglass mat tissue is a type of non-woven material made from glass fibers that are randomly oriented and bonded together with a binder. It is commonly used in various industries, including construction, automotive, and aerospace. The main purpose of fiberglass mat tissue is to provide strength, durability, and reinforcement to composite materials. It acts as a supporting layer between the resin and the glass fibers, helping to distribute stress and improve the overall mechanical properties of the final product. Fiberglass mat tissue has several advantages over other materials. It is lightweight, flexible, and easy to handle, making it ideal for applications that require complex shapes or curved surfaces. It also has excellent resistance to chemicals, moisture, and temperature changes, ensuring its longevity in harsh environments. In construction, fiberglass mat tissue is often used in the production of roofing materials, wall panels, and insulation boards. Its high strength-to-weight ratio makes it a popular choice for reinforcing concrete structures, such as bridges and buildings. In the automotive industry, fiberglass mat tissue is used in the manufacturing of car parts, such as body panels, bumpers, and interior components. It can enhance the structural integrity of these parts, making them more resistant to impacts and vibrations. In the aerospace industry, fiberglass mat tissue is employed in the production of aircraft components, such as wings, fuselages, and interiors. Its lightweight nature contributes to fuel efficiency and overall weight reduction, while still maintaining the necessary strength for safe flight. Overall, fiberglass mat tissue is a versatile and reliable material that plays a crucial role in enhancing the performance, durability, and safety of various products in different industries. Its unique properties make it an indispensable component in the production of composite materials.

- Q: How does fiberglass mat tissue compare to other types of insulation materials?

- Fiberglass mat tissue stands out as an insulation material with distinct characteristics and benefits when compared to other options. To begin with, its thermal insulation properties are remarkable. With its low thermal conductivity, it effectively minimizes heat transfer between the inside and outside of buildings. As a result, it helps maintain cooler temperatures in summer and warmer temperatures in winter, leading to energy savings and enhanced comfort. Moreover, fiberglass mat tissue excels in sound insulation. It effectively reduces noise transmission through walls and floors, creating a calm and peaceful indoor environment. This is particularly advantageous in commercial buildings, where noise reduction plays a vital role in productivity and customer satisfaction. Notably, fiberglass mat tissue is lightweight and flexible, making it easy to handle and install. It can be easily tailored to fit around obstacles such as pipes and ducts, ensuring a tight and efficient insulation barrier. This simplifies installation, saving time and labor costs during construction or renovation projects. Another significant advantage of fiberglass mat tissue is its fire resistance. As a non-combustible material, it does not contribute to the spread of fire. This is especially crucial in buildings prioritizing fire safety, such as hospitals, schools, and residential properties. Furthermore, fiberglass mat tissue is durable and long-lasting. It does not degrade or lose its insulation properties over time, guaranteeing consistent energy efficiency and performance for many years. This durability makes it a cost-effective choice, reducing the need for frequent replacement or maintenance. Lastly, fiberglass mat tissue is environmentally friendly. It is manufactured using recycled glass and sand, decreasing the demand for raw materials. Additionally, it is recyclable at the end of its lifespan, reducing waste and promoting sustainability. In conclusion, fiberglass mat tissue offers exceptional thermal and sound insulation, effortless installation, fire resistance, durability, and environmental benefits. While other insulation materials may present their own advantages, fiberglass mat tissue remains a versatile and reliable option for diverse applications.

- Q: Is fiberglass mat tissue suitable for automotive panel repairs?

- Yes, fiberglass mat tissue is suitable for automotive panel repairs.

- Q: How does fiberglass mat tissue perform in terms of moisture resistance?

- Fiberglass mat tissue is known for its excellent moisture resistance properties. The material is made up of tightly woven fiberglass strands, which create a barrier against moisture penetration. This makes it highly effective in preventing water or moisture from seeping through and damaging underlying surfaces or structures. Additionally, the resin used to bind the fiberglass strands together also adds an extra layer of protection against moisture, making it even more resistant to water and humidity. Overall, fiberglass mat tissue is a reliable choice when it comes to moisture resistance, making it suitable for various applications where preventing water damage is crucial.

- Q: Does fiberglass mat tissue provide any thermal insulation?

- Yes, fiberglass mat tissue does provide thermal insulation.

- Q: Can fiberglass mat tissue be used for making lightweight stairs?

- Making lightweight stairs is possible using fiberglass mat tissue. This material, composed of randomly oriented glass fibers bonded with resin, is widely used in the construction and manufacturing industries because of its strength, durability, and lightweight nature. By layering and molding fiberglass mat tissue, it can create a sturdy yet lightweight structure for stairs. Its impressive tensile strength and dimensional stability make it capable of supporting the weight of individuals using the stairs. Additionally, fiberglass mat tissue is resistant to moisture, chemicals, and UV rays, making it perfect for outdoor or high-moisture environments. Its fire-resistant properties further enhance its suitability for stairs, ensuring safety. In conclusion, fiberglass mat tissue is an excellent option for crafting lightweight stairs due to its combination of strength, durability, and resistance to various environmental factors.

- Q: What is the maximum temperature that fiberglass mat tissue can withstand?

- The maximum temperature that fiberglass mat tissue can withstand depends on the specific type of fiberglass material being used. Generally, most fiberglass mat tissues are designed to withstand temperatures up to 600 degrees Fahrenheit (315 degrees Celsius). However, it is important to note that the temperature tolerance can vary depending on factors such as the thickness of the material, the manufacturing process, and the specific application. It is always advisable to consult the manufacturer's specifications or technical data sheets for accurate information regarding the maximum temperature resistance of a particular fiberglass mat tissue.

- Q: Is fiberglass mat tissue resistant to mildew and rot?

- Yes, fiberglass mat tissue is resistant to mildew and rot. Fiberglass is made from fine glass fibers that are woven together to create a strong and durable material. These fibers are non-porous and do not absorb moisture, making fiberglass mat tissue highly resistant to the growth of mildew and the decomposition caused by rot. Additionally, fiberglass is often coated with protective finishes or treated with additives that further enhance its resistance to these types of biological degradation. This makes fiberglass mat tissue an excellent choice for applications where moisture or humidity is a concern, such as in bathrooms, outdoor structures, or areas prone to high humidity.

- Q: Can fiberglass mat tissue be used for interior decoration?

- Fiberglass mat tissue is an excellent option for interior decoration. This versatile material serves multiple purposes and is commonly utilized as a reinforcement for composite materials like fiberglass reinforced plastic (FRP). These materials are often employed to create decorative elements such as panels, wall coverings, and moldings. The fiberglass mat tissue offers a lightweight and durable solution with exceptional strength and resistance to moisture and chemicals. Moreover, it can be easily molded into various shapes and designs, making it a favored choice for interior decoration projects. Furthermore, the fiberglass mat tissue can be coated or painted to match any desired color or texture, enabling a wide array of creative possibilities in interior design.

Send your message to us

Fiberglass Mat Tissue Coated Aluminum Foil Heat Insulation Glass Wool Felt

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords