Fiberglass Mat Tissue Chopped Strand Mat for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Chopped Strand Mat for Boat Building Fiberglass Mat

Introduction:

Chopped Strand Mat is characterized by good combination of resin, easy operation, good wet strength retention, good laminate transparency and low cost. It is suitable for the application by hand lay-up FRP moldings, such as, various sheets and panels, boat hulls, boat tubs, cooling towers, corrosion resistant, vehicles, etc.

Function:

Fiberglass chopped strand mat is chopped using the "E" chopped glass and emulsion adhesive bond. It is suitable for hand lay and can enhance the unsaturaed ployester resins.

Product Features:

Consistent thickness and stiffness;

Rapid impregnating and good compatibility with resin;

Superior wet through with less air trap;

Good mechanical properties and high strength of parts.

Superior acid corrosion resistance

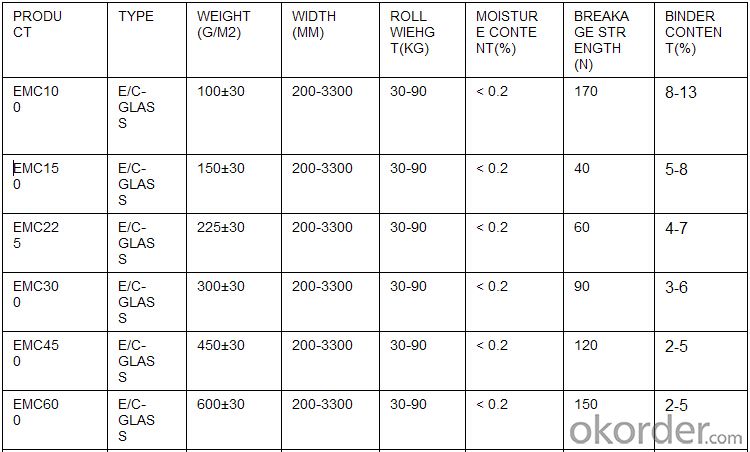

Technical Data:

Packaging:

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: Can fiberglass mat tissue be used for mold making?

- No, fiberglass mat tissue is not typically used for mold making. Fiberglass mat tissue is a thin, lightweight material made from woven fiberglass strands. It is mainly used for reinforcing and strengthening composite materials, such as fiberglass laminates. For mold making, materials such as silicone rubber, urethane rubber, or latex are commonly used. These materials are flexible and can capture intricate details, making them ideal for creating molds of objects. Additionally, they have good release properties, which allow for easy removal of the mold from the original object. Fiberglass mat tissue, on the other hand, is rigid and does not have the flexibility required for mold making. It is more suitable for applications where strength and reinforcement are needed, rather than capturing detailed shapes or creating molds. Therefore, if you are looking to make molds, it is recommended to choose a material specifically designed for that purpose, rather than using fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for electrical transformers?

- Electrical transformers can utilize fiberglass mat tissue, a material with superb electrical insulation properties, as an insulation material. In the manufacturing of transformers, this material is commonly employed due to its exceptional electrical insulation characteristics. Constructed from delicate glass fibers that are firmly bonded together with a resin, fiberglass mat tissue forms a robust and long-lasting substance. Remarkably, it possesses the ability to endure high temperatures and possesses a strong dielectric strength, rendering it ideal for utilization in electrical transformers. Moreover, its lightweight and flexible nature facilitates effortless handling and installation into transformer components. Furthermore, it displays resistance against moisture, chemicals, and fire, thereby further enhancing its suitability for use in transformer applications. In conclusion, fiberglass mat tissue represents a dependable and efficient choice for insulation purposes in electrical transformers.

- Q: What is the dimensional stability of fiberglass mat tissue?

- The dimensional stability of fiberglass mat tissue refers to its ability to maintain its size and shape under various conditions. Fiberglass mat tissue is known for its excellent dimensional stability, making it highly resistant to shrinking, expanding, or warping. This stability is achieved through the manufacturing process, which involves bonding glass fibers together using a binder material. This binder not only ensures the integrity of the mat tissue but also helps it maintain its dimensional stability over time. Additionally, the inherent properties of fiberglass, such as its high strength and stiffness, contribute to its exceptional dimensional stability. These characteristics make fiberglass mat tissue a popular choice in various applications, including construction, automotive, and aerospace industries, where consistent dimensions are crucial for optimal performance and durability.

- Q: What are the main applications of fiberglass mat tissue?

- Fiberglass mat tissue, an adaptable material, finds diverse applications in industries like construction, automotive, aerospace, and marine. Key uses of this material comprise: 1. Construction: Fiberglass mat tissue commonly reinforces and strengthens building materials in the construction industry, including roofing shingles, wallboards, and cementitious products. It enhances tensile strength and durability, rendering the structures more resistant to cracks, water damage, and weathering. 2. Automotive: The manufacturing of automotive parts, such as dashboards, door panels, and trunk liners, heavily relies on fiberglass mat tissue. It imparts structural integrity, sound insulation, and heat resistance, contributing to safer and more comfortable vehicles. 3. Aerospace: Lightweight composite materials used in aircraft structures benefit from the inclusion of fiberglass mat tissue. This material aids in reducing overall weight, improving fuel efficiency, and enhancing performance. 4. Marine: Fiberglass mat tissue plays a significant role in boat and shipbuilding. It provides strength, stiffness, and resistance to water and corrosion in the construction of hulls, decks, and other components. Its lightweight, durability, and low maintenance requirements make it preferable to traditional materials like wood. 5. Electrical and Electronics: Fiberglass mat tissue serves electrical insulation purposes, such as transformer boards, electrical cabinets, and switchgear. Its excellent dielectric properties, heat resistance, and mechanical strength ensure the safety and reliability of electrical equipment. 6. Filtration: Various filtration applications, such as air filters, water filters, and oil filters, employ fiberglass mat tissue. It acts as a filtration medium, capturing and eliminating impurities, dust, and particles from air, water, or oil, thereby enhancing the quality and purity of filtered substances. In summary, fiberglass mat tissue finds extensive use across industries due to its strength, durability, lightweight nature, and resistance to environmental factors. Its versatility enables it to be an indispensable component in diverse applications, contributing to the development of safer, sturdier, and more efficient products.

- Q: Can fiberglass mat tissue be used for insulating radiant floors?

- Indeed, insulating radiant floors is possible with the use of fiberglass mat tissue. This material, known for its exceptional thermal properties and moisture resistance, is widely favored for insulation purposes. Specifically engineered to enhance the strength and endurance of the insulation layer, fiberglass mat tissue effectively inhibits heat loss and enhances energy efficiency in radiant floor systems. By creating a shield between the heated floor and the colder ground or subfloor, it effectively prevents heat escape. Moreover, installing fiberglass mat tissue is hassle-free, as it can be easily tailored to fit any desired shape or size. This remarkable adaptability makes it a versatile option for insulating radiant floors.

- Q: Is fiberglass mat tissue biodegradable?

- No, fiberglass mat tissue is not biodegradable.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue is determined by several factors, including the mat's thickness, fiber density, and the inclusion of additional materials or coatings. In general, fiberglass exhibits low thermal resistance, signifying its excellent heat conductivity. Nevertheless, when employed as insulation, the thickness and density of the fiberglass mat can elevate its thermal resistance, enhancing its ability to reduce heat transfer. It is crucial to acknowledge that precise thermal resistance values may differ based on the product and application, hence it is advisable to consult the manufacturer's specifications for precise information.

- Q: Can fiberglass mat tissue be used for reinforcing wind turbine blades?

- Wind turbine blades can be reinforced using fiberglass mat tissue, a lightweight and flexible material composed of thin glass fibers bonded with resin. This material is frequently employed in various applications requiring strength and durability, including wind turbine blade construction. To efficiently harness wind power, turbine blades must possess strength while remaining lightweight. They face various forces, such as wind loads, vibrations, and extreme weather conditions. Fiberglass mat tissue is an ideal option for reinforcing these blades due to its exceptional mechanical properties. It offers high tensile strength and stiffness, enabling the blades to withstand the stress and strain they encounter during operation. Furthermore, fiberglass mat tissue exhibits excellent resistance to corrosion and fatigue, which are crucial factors for ensuring the long-term performance of wind turbine blades. It also maintains good dimensional stability, preserving the shape and integrity of the blades over time. Moreover, fiberglass mat tissue can be easily shaped and molded, allowing for the creation of complex and aerodynamic blade designs. It can be layered and combined with other materials, such as epoxy resin, to form a composite structure that optimizes the strength and performance of wind turbine blades. In conclusion, fiberglass mat tissue is a widely used and suitable material for reinforcing wind turbine blades. Its lightweight nature, high strength, corrosion resistance, and moldability make it an excellent choice for maintaining the structural integrity and efficiency of wind turbines.

- Q: Is fiberglass mat tissue resistant to UV radiation?

- No, fiberglass mat tissue is not resistant to UV radiation.

- Q: Can fiberglass mat tissue be painted over?

- Yes, fiberglass mat tissue can be painted over. However, there are a few considerations that need to be taken into account. First, it is important to ensure that the fiberglass mat tissue is clean and free from any dirt, grease, or other contaminants before painting. This can be achieved by cleaning the surface with a mild detergent and water, followed by thorough rinsing and drying. Secondly, it is recommended to apply a primer before painting to improve adhesion and promote a smoother finish. A high-quality primer specifically designed for use on fiberglass surfaces should be used, following the manufacturer's instructions for application. Finally, when choosing the paint, it is crucial to select one that is compatible with fiberglass materials. Acrylic or epoxy-based paints are often recommended as they provide good adhesion and durability on fiberglass surfaces. By following these steps and using appropriate materials, it is possible to paint over fiberglass mat tissue successfully. However, it is always advisable to consult with a professional or follow the manufacturer's recommendations for optimal results.

Send your message to us

Fiberglass Mat Tissue Chopped Strand Mat for Boat Building

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 kg

- Supply Capability:

- 1000000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords