Fiberglass Mat Tissue - Multiaxial Fabric-UD, 1050gsm (90°:600g, Chopping:450g)

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

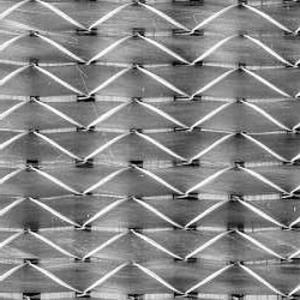

Structure of Fiberglass Multiaxial Fabric-UD Description:

An engineering material, which has many excellent characterstics, such as anti-burning, corrosion resistent, stable structure, heat-isolating, minimum elongated shrinkage, high intensity, etc. This new material product has already covered many domains such as electric appliance, electronic, transportation, chemical engineering, architectural engineering, heat insulation, sound absorption, fire prevention and environmental protection, etc. According to fabric organizational structure and appearance, there are such kind of products: plain weave, twill weave, satin weave, gauze weave.

Main Features of the Fiberglass Multiaxial Fabric-UD:

1)Plain veave,even thickness and low fuzz;

2)High strength in both warp and weft direction;

3)Incombustibility,corrosion resistance and heat resistance;

4)E-Grade Fabric (E-fiberglass Textile Cloth) has excellent electricity insulation property.

Fiberglass Multiaxial Fabric-UD Images:

Unidirectional Specification:

Code | Total weight g/m2 | Weight of each layer, g/m2 | Width mm | ||||

0° | 90° | +45° | -45° | Chopping | |||

E-L300 | 350 | 300 | 50 | 200~2600 | |||

E-L350 | 400 | 350 | 50 | 200~2600 | |||

E-L400 | 450 | 400 | 50 | 200~2600 | |||

E-L450 | 500 | 450 | 50 | 200~2600 | |||

E-L500 | 550 | 500 | 50 | 200~2600 | |||

E-L600 | 650 | 600 | 50 | 200~2600 | |||

E-L650 | 700 | 650 | 50 | 200~2600 | |||

E-L900 | 930 | 880 | 50 | 200~2600 | |||

E-L700/200 | 950 | 700 | 50 | 200 | 200~2600 | ||

E-T200 | 200 | 200 | 200~2600 | ||||

E-T450 | 450 | 450 | 200~2600 | ||||

E-T500 | 500 | 500 | 200~2600 | ||||

E-TM300/300 | 600 | 300 | 300 | 200~2600 | |||

E-TM600/450 | 1050 | 600 | 450 | 200~2600 | |||

E-LM750/200 | 950 | 750 | 200 | 200~2600 | |||

FAQ of Chopped strand mat

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

- Q: What is the moisture resistance of fiberglass mat tissue?

- The moisture resistance of fiberglass mat tissue is high.

- Q: Is fiberglass mat tissue suitable for insulation in hospitals?

- Yes, fiberglass mat tissue is suitable for insulation in hospitals. Fiberglass mat tissue is a lightweight and cost-effective material that offers excellent thermal insulation properties. It can effectively regulate temperature and reduce heat loss, making it an ideal choice for hospitals where maintaining a comfortable and controlled environment is crucial. Additionally, fiberglass mat tissue is non-combustible and resistant to mold, ensuring a safe and hygienic environment in hospitals. Its durability and ease of installation also make it a practical choice for insulation in healthcare facilities.

- Q: Can fiberglass mat tissue be used for insulation in chemical storage tanks?

- Indeed, insulation in chemical storage tanks can be achieved using fiberglass mat tissue. The exceptional insulation properties of fiberglass render it a fitting substance for tanks that house chemicals. Typically composed of finely interwoven glass fibers, the fiberglass mat tissue constitutes a robust and long-lasting material. Its application to the inner walls of the tank effectively insulates and thwarts heat transfer. Furthermore, fiberglass exhibits corrosion resistance and can endure the detrimental effects of the chemicals commonly stored within these tanks, making it an optimal option for insulation in chemical storage tanks.

- Q: Is fiberglass mat tissue suitable for chemical storage tanks?

- Yes, fiberglass mat tissue is suitable for chemical storage tanks. It is highly resistant to corrosion caused by various chemicals and provides excellent strength and durability to withstand the harsh conditions of chemical storage. Additionally, it helps in preventing leakage and ensures the long-term integrity of the tanks.

- Q: Is fiberglass mat tissue resistant to compression?

- Indeed, compression resistance is a quality possessed by fiberglass mat tissue. Comprising numerous layers of delicate glass fibers that are bound together by a binder, this material exhibits exceptional structural integrity and strength. Consequently, it can endure substantial loads without distorting or compromising its shape. This remarkable attribute renders fiberglass mat tissue highly sought-after in numerous sectors, including construction, automotive, aerospace, and marine industries, where resistance to compression is imperative. Furthermore, fiberglass mat tissue is renowned for its exceptional dimensional stability, which further augments its ability to withstand compression.

- Q: Does fiberglass mat tissue provide any mold resistance?

- While fiberglass mat tissue alone does not possess natural mold resistance, its combination with other mold-resistant materials and proper construction techniques can aid in preventing mold. The fiberglass mat tissue itself may not resist mold growth, but it can be employed as a strengthening layer in mold-resistant building materials like mold-resistant drywall or sheathing. These materials are specifically engineered to hinder the growth of mold and mildew by incorporating additives or coatings. It is also crucial to guarantee the correct installation and upkeep of these materials to minimize moisture accumulation and establish an unfavorable setting for mold to thrive.

- Q: What are the different finishing options available for fiberglass mat tissue?

- There are several different finishing options available for fiberglass mat tissue. One common finishing option is a resin coating. This involves applying a layer of resin to the surface of the fiberglass mat tissue. The resin helps to protect the fibers and provide added strength and durability. It can also improve the appearance of the material, giving it a smooth and glossy finish. Another finishing option is a fire-retardant treatment. This involves applying a special chemical treatment to the fiberglass mat tissue that helps to reduce its flammability. This is especially important in applications where fire safety is a concern, such as in the construction industry. Additionally, fiberglass mat tissue can be finished with a colored pigment. This involves adding a dye or pigment to the material during the manufacturing process. This allows for a wide range of color options, making the fiberglass mat tissue more visually appealing and versatile. Some manufacturers also offer a textured finish for fiberglass mat tissue. This involves adding a pattern or texture to the surface of the material, creating a more tactile and aesthetically pleasing product. This can be particularly useful in applications where grip or slip resistance is required. Lastly, fiberglass mat tissue can be finished with a laminated backing. This involves bonding the fiberglass mat tissue to a separate backing material, such as foam or fabric. This provides additional strength and flexibility to the material, making it suitable for a wider range of applications. Overall, the different finishing options available for fiberglass mat tissue allow for customization and adaptation to specific needs and requirements. Whether it's adding strength, fire resistance, color, texture, or additional backing, these finishing options enhance the performance and appearance of fiberglass mat tissue in various industries.

- Q: What about high temperature fiberglass?

- The glass will not melt at this temperature, but the silica gel may soften. Glass fiber may break, preferably not for direct contact with food, and may enter the body

- Q: What are the different manufacturing processes for fiberglass mat tissue?

- There are several different manufacturing processes for fiberglass mat tissue, each of which is designed to produce a specific type of mat with unique properties. One common manufacturing process is the wet-laid process. In this method, glass fibers are first chopped into small pieces and then dispersed in a water-based slurry. The slurry is then spread onto a moving screen or belt, allowing the water to drain away and leaving behind a mat of randomly oriented fibers. The mat is then dried and further processed to achieve the desired thickness and density. Another manufacturing process is the dry-laid process. In this method, glass fibers are first formed into a loose, fluffy mat using air or mechanical means. The loose fibers are then bonded together using a binder material, such as a resin or latex, which is sprayed onto the fibers. The binder cures, creating a cohesive mat with controlled thickness and density. A third manufacturing process is the stitch-bonded process. This method involves mechanically stitching individual glass fibers together using a series of needles. The needles pierce the fibers and interlock them, creating a bonded fabric. This process allows for the production of mats with high strength and dimensional stability. Finally, there is the spunbond process. This process involves extruding molten glass through fine spinnerets to form continuous filaments. The filaments are then collected onto a moving belt or screen, where they are bonded together using heat or a binder. This process produces mats with uniform fiber distribution and high strength. Overall, the choice of manufacturing process for fiberglass mat tissue depends on the desired properties of the final product, such as strength, thickness, density, and dimensional stability. Each process has its own advantages and disadvantages, and manufacturers will select the most suitable process based on their specific requirements.

- Q: Can fiberglass mat tissue be recycled?

- Yes, fiberglass mat tissue can be recycled. It is a common practice to recycle fiberglass waste, including fiberglass mat tissue, by breaking it down into smaller fibers and using it as a raw material in various industries such as insulation, construction, and automotive. Recycling fiberglass helps to reduce waste and conserves resources.

Send your message to us

Fiberglass Mat Tissue - Multiaxial Fabric-UD, 1050gsm (90°:600g, Chopping:450g)

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords