Fiberglass Mat Tissue Glass Fiber Roving 2400 tex Glass Fiber Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Glass Fiber Roving 2400 Tex Glass Fiber Roving Price

Introduction:

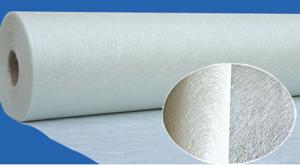

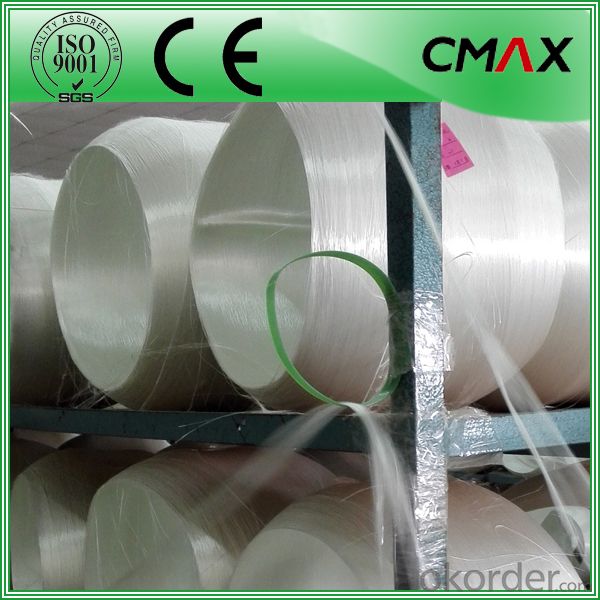

E-glass sprary-up roving, fiberglass gun roving, fiberglass roving is coated with a silance-based sizing, compatible with unsaturated polyester, vinyl ester and polyurethane resins.

It is a versatile general purpose spray-up roving used to manufacture boats, bathroom sinks ,yacht, sanitary ware, swimming pool and automotive parts and also pipe by centrifugal casting process.

Product Features:

1)Silane based coupling agent which delivers most balanced sizing properties.

2)Special sizing formulation which delivers good compatibility with martix resin.

3)Consistent fiber linear density,good mold ability and dispersion

4)Excellent mechanical properties of composite products

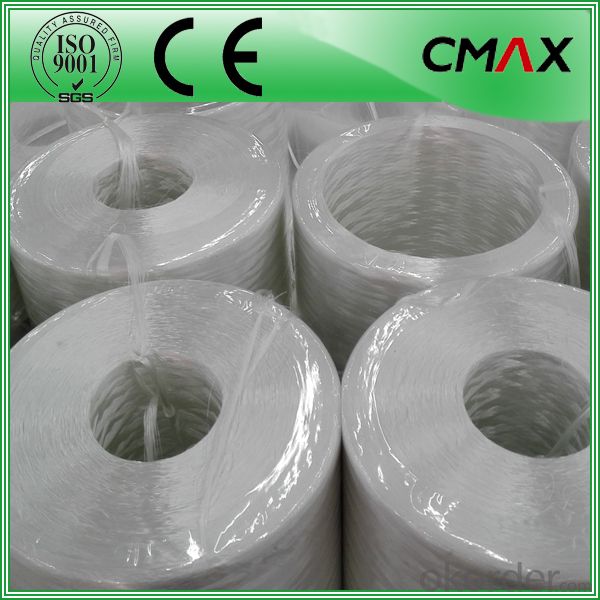

Packaging:

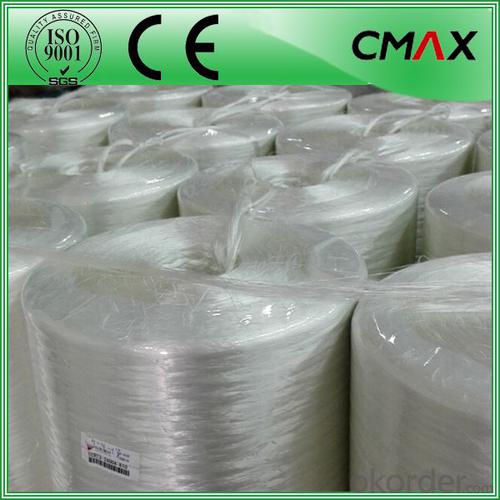

Product is manufactured in form of a roll wrap on a paper tube then after packed in a plastic bag and placed in a cardboard carton. Rolls can be loaded in a container directly or on pallets.

Deposited:

Chopped Strand Mat should be stored in dry, cool, clean and rainproof area. Recommended temperature range of storage is between 15-30 and relative humidity between 40%-70%.

FAQ:

Is sample available ?

Yes, we provide the free samples, but customers themselves need pay the shipping fee

What's your MOQ?

Our MOQ is one 1*20' full container loading

How do you pack the fiberglass

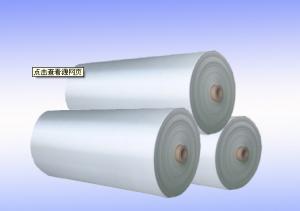

(1) First, the mat is in roll packed in White PE fIlm.

(2) Then the rolls packed in the carton

4.Which knid of payment terms can you accept?

We can accept 30% prepayment, 70% payment before shippment. LC is also accepted

- Q: How does the roll diameter of fiberglass mat tissue affect its handling?

- The roll diameter of fiberglass mat tissue affects its handling by influencing its weight, ease of maneuverability, and the amount of material that can be handled at once. A larger roll diameter may be heavier and more challenging to handle, requiring more effort and potentially causing strain. Additionally, a larger roll diameter may limit maneuverability, making it harder to transport or position the material. Conversely, a smaller roll diameter is typically lighter and easier to handle, allowing for more flexibility in moving and manipulating the fiberglass mat tissue.

- Q: Can fiberglass mat tissue be used for repairing fiberglass structures?

- Yes, fiberglass mat tissue can be used for repairing fiberglass structures. It is commonly used in the construction and repair of fiberglass boats, car bodies, and other fiberglass structures. The mat tissue provides added strength and reinforcement to the damaged area, making it an effective solution for repairing fiberglass structures.

- Q: Can fiberglass mat tissue be used for windbreak panels?

- Yes, fiberglass mat tissue can be used for windbreak panels. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in various applications such as insulation, reinforcing materials, and structural support. It is known for its high strength-to-weight ratio, durability, and resistance to weather and environmental conditions. When used in windbreak panels, fiberglass mat tissue can provide additional reinforcement and stability to the panels. It can help withstand strong winds and prevent damage or breakage, making it an effective choice for windbreak panels. Moreover, fiberglass mat tissue is also known for its excellent thermal and acoustic insulation properties. This can be beneficial in windbreak panels as it can help to reduce noise and regulate temperature, creating a more comfortable and protected environment. Additionally, fiberglass mat tissue is fire-resistant, making it a safe option for windbreak panels. Overall, fiberglass mat tissue can be a suitable and reliable material for windbreak panels due to its strength, durability, insulation properties, and resistance to environmental conditions.

- Q: Can fiberglass mat tissue be used for insulation in research laboratories?

- Yes, fiberglass mat tissue can be used for insulation in research laboratories. It is a common material choice due to its excellent thermal insulation properties and fire resistance. Additionally, fiberglass mat tissue is lightweight, durable, and easy to install, making it suitable for various insulation applications in laboratories.

- Q: How is fiberglass mat tissue bonded to surfaces?

- Adhesive materials are commonly utilized to bond fiberglass mat tissue to surfaces. To initiate the bonding process, the adhesive is applied onto the surface where the fiberglass mat tissue will be attached. Typically, a two-part epoxy resin or a specialized fiberglass adhesive, specifically formulated for bonding fiberglass materials, is used. Following the manufacturer's instructions, the adhesive is thoroughly mixed and then evenly spread onto the surface using a brush, roller, or trowel. With utmost care, the fiberglass mat tissue is then placed onto the adhesive-covered surface and firmly pressed down to ensure optimal adhesion. Subsequently, the adhesive is left to cure for the recommended duration, allowing it to solidify and establish a robust bond between the fiberglass mat tissue and the surface. This bonding technique guarantees the secure attachment of the fiberglass mat tissue to the surface, offering reinforcement, protection, or other desired attributes based on the specific application.

- Q: Can fiberglass mat tissue be used for insulation?

- Yes, fiberglass mat tissue can be used for insulation. It is commonly used in the construction industry as a thermal and sound insulation material. The fiberglass mat tissue is made up of fine fibers of glass that are woven into a mat-like structure. This structure traps air and creates a barrier that helps to reduce heat transfer, keeping the desired area insulated and maintaining a comfortable temperature. Additionally, fiberglass mat tissue is also resistant to moisture, fire, and pests, making it a suitable choice for insulation in various applications.

- Q: How does fiberglass mat tissue compare to fiberglass mesh?

- Fiberglass mat tissue and fiberglass mesh are both used for reinforcing and strengthening various materials, but they have key differences in their composition and applications. Fiberglass mat tissue is a thin, non-woven material made up of randomly oriented glass fibers bonded together with a binder. It is typically used for surface finishing, especially in the production of composite materials, where it provides a smooth and aesthetically pleasing surface. Fiberglass mat tissue is also used for insulation purposes due to its thermal and acoustic properties. On the other hand, fiberglass mesh consists of woven glass fibers, forming a grid-like pattern. This mesh is commonly used for reinforcement in construction and other applications where strength and durability are required. It is often used in combination with cement or other bonding agents to enhance the structural integrity of walls, floors, and other surfaces. In summary, while both fiberglass mat tissue and fiberglass mesh serve specific purposes in reinforcement, they differ in their composition, with mat tissue being non-woven and mesh being woven. The choice between the two depends on the specific requirements of the project, such as the need for surface finishing or structural reinforcement.

- Q: What is the thermal stability of fiberglass mat tissue?

- The thermal stability of fiberglass mat tissue is quite high. It can withstand high temperatures without significant degradation or loss of its structural integrity.

- Q: Can fiberglass mat tissue be used for making lightweight doors?

- Yes, fiberglass mat tissue can be used for making lightweight doors. It is a lightweight material that offers excellent strength and durability, making it suitable for door construction. Additionally, fiberglass mat tissue can provide insulation properties and resistance to moisture, making it a viable option for lightweight door manufacturing.

- Q: What are the key properties of fiberglass mat tissue?

- Fiberglass mat tissue is a versatile material that possesses several key properties. Firstly, it is made from fine glass fibers that are randomly oriented and bonded together with a binder. This random orientation allows for greater strength and flexibility compared to other materials. One key property of fiberglass mat tissue is its high tensile strength. It can withstand significant amounts of pulling or stretching forces without breaking, making it ideal for applications that require durability and resistance to mechanical stress. Another important property is its excellent thermal insulation capabilities. Fiberglass mat tissue has a low thermal conductivity, meaning it can effectively prevent the transfer of heat. This property makes it suitable for use in insulation applications where it helps to conserve energy and maintain a stable temperature. Fiberglass mat tissue also exhibits good chemical resistance. It is not easily affected by exposure to chemicals, acids, or alkaline substances. This property makes it a suitable choice for applications such as chemical storage tanks or pipes where resistance to corrosion is required. Furthermore, fiberglass mat tissue has excellent moisture resistance. It does not absorb water easily, which makes it resistant to rot and decay. This property makes it suitable for outdoor applications or in environments with high humidity. Lastly, fiberglass mat tissue is lightweight and easy to handle. It can be easily cut, shaped, and installed, making it a convenient material for various applications. In summary, the key properties of fiberglass mat tissue include high tensile strength, thermal insulation capabilities, chemical resistance, moisture resistance, and lightweight. These properties make it a versatile material that can be used in a wide range of applications such as construction, automotive, aerospace, and marine industries.

Send your message to us

Fiberglass Mat Tissue Glass Fiber Roving 2400 tex Glass Fiber Roving Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t

- Supply Capability:

- 1000000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords