Fiberglass Mat Tissue E Glass Woven Roving Fabric for Hand Layup and Robot Process

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Brief Introduction

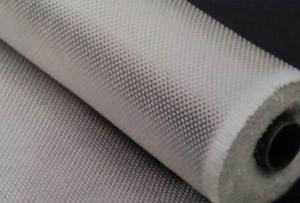

Fiber Glass Woven Roving Fabrics are bidirectional fabric made by interweaving direct rovings.

Fiber Glass Woven Roving Fabrics are compatible with unsaturated polyester, vinyl ester, epoxy and phenolic resins.

Fiber Glass Woven Roving Fabrics are a high-performance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities.

2.Product Features

Warp and weft rovings aligned in a parallel and flat manner, resulting in uniform tension

Densely aligned fibers, resulting in high dimensional stability and making handling easy

Good mechanical properties and high strength of parts

3.Product Specifications

Property | Area Weight | Moisture Content | Size Content | Width |

(%) | (%) | (%) | (mm) | |

Test Method | IS03374 | ISO3344 | ISO1887 | |

EWR200 | ±7.5 | ≤0.15 | 0.4-0.8 | 20-3000 |

EWR270 | ||||

EWR300 | ||||

EWR360 | ||||

EWR400 | ||||

EWR500 | ||||

EWR600 | ||||

EWR800 |

Special specification can be produce according to customer requirements.

4.FAQ

4.FAQ

Storage:

Unless otherwise specified,It should be stored in a dry, cool and rain-proof area. It is recommended that the room temperature and humidity should be always maintained at 15℃~35℃ and 35%~65% respectively.

Payment term:

The payment term can be T/T in advance or L/C.The products will be ready in 20 days after getting the payment or L/C.

- Q: How does the weight of fiberglass mat tissue affect its performance?

- The weight of fiberglass mat tissue directly affects its performance as a lighter tissue allows for better flexibility and ease of handling, while a heavier tissue provides increased strength and durability.

- Q: How is fiberglass mat tissue used in the construction industry?

- Fiberglass mat tissue is widely used in the construction industry for various applications. This material is made up of thin strands of glass fibers that are bonded together with a resin. It offers several properties that make it suitable for construction purposes. One common use of fiberglass mat tissue is in the production of roofing materials. It is often used as a reinforcement layer in roofing shingles or sheets. The fiberglass mat tissue adds strength and durability to the roof, making it more resistant to weather elements such as wind, rain, and hail. Additionally, it helps to prevent cracking and splitting, prolonging the lifespan of the roofing material. Another application of fiberglass mat tissue in the construction industry is in the production of composite materials. It is commonly used as a reinforcement layer in composite panels and boards. The fiberglass mat tissue enhances the strength and stiffness of the composite material, making it suitable for various structural applications. It is also lightweight, which makes it an ideal choice for building materials that require both strength and reduced weight. Fiberglass mat tissue is also used in the construction of walls and ceilings. It can be applied as a layer between the gypsum board and the insulation material to provide additional strength and resistance to impacts. This helps to prevent cracks and damage to the walls or ceilings, enhancing the overall structural integrity of the building. Furthermore, fiberglass mat tissue finds application in the construction of pipes and tanks. It is used as a reinforcement layer in the manufacturing of fiberglass-reinforced plastic (FRP) pipes and tanks. The fiberglass mat tissue adds strength and rigidity to the FRP structure, making it suitable for various industrial applications, including chemical processing, wastewater treatment, and oil and gas industries. In conclusion, fiberglass mat tissue is widely used in the construction industry for its strength, durability, and lightweight properties. It is utilized in roofing materials, composite panels, walls, ceilings, pipes, and tanks, among other applications. Its versatility and performance make it a preferred choice among construction professionals for enhancing the structural integrity of various building components.

- Q: How long does fiberglass mat tissue typically last?

- The lifespan of fiberglass mat tissue can vary depending on various factors such as the quality of the material, its exposure to environmental conditions, and the level of maintenance. On average, fiberglass mat tissue can last anywhere from 20 to 30 years. However, with proper installation and regular upkeep, it is possible for it to last even longer. It is important to note that regular inspection and maintenance can help identify any signs of wear or damage, allowing for timely repairs or replacements to ensure its longevity.

- Q: How is fiberglass mat tissue used in the production of printed circuit boards?

- Fiberglass mat tissue is used as a reinforcement material in the production of printed circuit boards (PCBs). It is typically impregnated with epoxy resin and then laminated onto the copper-clad laminates. This helps to improve the mechanical strength and stability of the PCB, making it more resistant to bending, warping, and other forms of physical stress. Additionally, the fiberglass mat tissue provides insulation between the copper layers, preventing short circuits and enhancing the overall performance and reliability of the PCBs.

- Q: What is the expected lifespan of fiberglass mat tissue in outdoor applications?

- The expected lifespan of fiberglass mat tissue in outdoor applications can vary depending on several factors such as exposure to weather conditions, maintenance, and quality of the material. However, on average, fiberglass mat tissue can last for approximately 20 to 30 years when properly installed and maintained.

- Q: Is fiberglass mat tissue suitable for construction applications?

- Yes, fiberglass mat tissue is suitable for construction applications. It is commonly used as a reinforcement material in various construction projects due to its high strength, durability, and resistance to corrosion. It provides added structural integrity and stability to buildings, bridges, and other infrastructure. Additionally, fiberglass mat tissue is lightweight and easy to handle, making it a convenient choice for construction applications.

- Q: How does the width and length of fiberglass mat tissue affect its application?

- The width and length of fiberglass mat tissue can affect its application by determining how easily it can be cut and maneuvered during installation. A wider and longer mat tissue may provide better coverage on larger surfaces, reducing the need for multiple pieces and potentially saving time and effort. Additionally, the length of the mat tissue can influence its strength and stability, as longer fibers may provide better reinforcement properties. Ultimately, the choice of width and length should be based on the specific requirements of the application, such as the size of the area to be covered or the desired level of reinforcement.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Certainly, automotive parts can be repaired using fiberglass mat tissue. This versatile material is commonly employed to reinforce and repair various surfaces, including automotive components. It proves particularly valuable when restoring fiberglass parts such as car bodies and panels. Fiberglass mat tissue possesses a thin and flexible composition, comprised of randomly arranged fiberglass strands. This design enables easy molding and shaping to match the contours of the damaged automotive part. Typically, the mat tissue is applied alongside a resin like polyester or epoxy, which binds the fibers together, yielding a robust and enduring repair. When utilized for automotive repairs, fiberglass mat tissue offers numerous advantages. Firstly, its lightweight nature is crucial for maintaining the overall weight and balance of the vehicle. Furthermore, it exhibits resistance to corrosion and can withstand exposure to diverse weather conditions, rendering it suitable for all automotive repair applications. Moreover, fiberglass mat tissue is renowned for its high tensile strength, enabling it to endure the stresses and strains encountered during normal use of automotive parts. As a result, it becomes an ideal choice for fixing damaged or weakened areas, such as cracks, holes, or dents in car bodies or panels. In conclusion, fiberglass mat tissue is a highly effective option for repairing automotive parts, especially those constructed from fiberglass. Its versatility, lightweight composition, corrosion resistance, and high tensile strength make it an exceptional choice for restoring the structural integrity and appearance of damaged automotive components.

- Q: Can fiberglass mat tissue be used for insulation?

- Fiberglass mat tissue can indeed be utilized for insulation purposes. It finds widespread application within the construction sector, serving as an effective material for thermal and sound insulation. Comprised of delicate glass fibers intricately woven into a mat-like formation, this tissue structure effectively captures air, establishing a barrier that minimizes heat transfer. Consequently, it ensures insulated spaces retain a pleasant temperature. Moreover, fiberglass mat tissue boasts resistance against moisture, fire, and pests, rendering it an excellent insulation option across diverse situations.

- Q: Can fiberglass mat tissue be used for thermal insulation?

- Indeed, thermal insulation can be achieved through the utilization of fiberglass mat tissue. Comprised of delicate glass fibers that are skillfully intertwined to produce a robust and supple substance, this material boasts remarkable thermal insulation attributes. Its capacity to resist heat transfer and exhibit low thermal conductivity accounts for its excellent properties in this regard. In order to impede the dissipation or absorption of heat, fiberglass mat tissue can be effectively employed to insulate not only walls but also roofs and other surfaces. Within the construction industry, it is a prevalent practice to implement this material with the aim of advancing energy efficiency and curtailing expenses associated with heating or cooling. Moreover, the fire-resistant, moisture-resistant, and durable nature of fiberglass mat tissue renders it highly suitable for an array of thermal insulation applications.

Send your message to us

Fiberglass Mat Tissue E Glass Woven Roving Fabric for Hand Layup and Robot Process

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 16000 kg

- Supply Capability:

- 160000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords