Fiberglass Mat Tissue E Glass Fiber Woven Roving for Boat Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

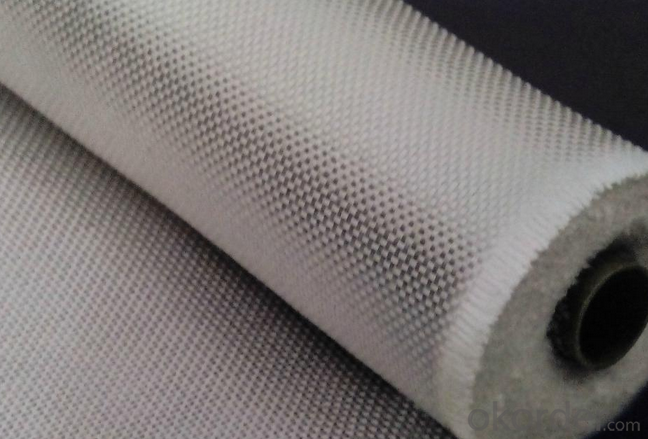

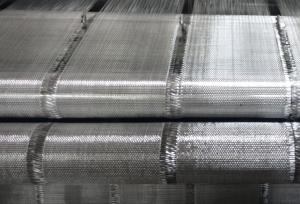

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1) Woven roving is a kind of evenly distributed material which owns high strength on both side with high intensity, the fiber content and strength is even higher during the production of FRP products.

2) Benefit from the production procedure and the material itself, the fabric maintains high percentage of its material strength, and also very easy for the resin to penetrate.

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

1. Your inquiry will be replied within 24hours

2. Well-trained and experienced staffs will answer all your inquiries at first time..

3. All our products have warranties.

4. Offering the support to solve the problem during the application or selling period.

5. Good quality with competitive price.

6. The same quality of samples and mass products is granted.

- Q: What are the potential limitations of using fiberglass mat tissue?

- Using fiberglass mat tissue comes with several potential limitations. To begin with, fiberglass mat tissue tends to be more brittle compared to other materials. This means that it may crack or break easily under certain conditions, especially if it is subjected to high levels of stress or impact. This brittleness can restrict its use in applications where durability and flexibility are important. Moreover, fiberglass mat tissue is not naturally resistant to moisture. If it is exposed to water or high humidity for extended periods, it can absorb moisture and lose its structural integrity. Consequently, it may not be suitable for use in environments where moisture resistance is crucial. In addition, working with fiberglass mat tissue can be challenging due to its sharp edges and fibers. Taking special precautions such as wearing protective clothing and using proper handling techniques is necessary to avoid injury. This can add complexity and cost to the use of fiberglass mat tissue in certain applications. Furthermore, cutting or manipulating fiberglass mat tissue can release fine particles or fibers into the air. Inhaling these particles can pose health risks, potentially leading to respiratory issues or irritation. To minimize these risks, it is essential to take proper safety measures such as using masks and ensuring adequate ventilation. Lastly, fiberglass mat tissue is relatively expensive compared to some alternative materials. Its production process involves multiple steps and specialized equipment, which contributes to higher costs. As a result, its use may be limited in applications where cost-effectiveness is a primary concern. In conclusion, while fiberglass mat tissue offers various advantages in terms of strength, insulation, and fire resistance, it is crucial to carefully consider its potential limitations before choosing it for a specific application.

- Q: Does fiberglass mat tissue require any maintenance?

- Fiberglass mat tissue does not typically require any maintenance once it has been installed. This material is designed to be durable and long-lasting, capable of withstanding various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance option for many applications. However, it is important to note that proper installation is crucial to ensure the longevity and effectiveness of fiberglass mat tissue. It should be installed according to manufacturer guidelines, ensuring that it is properly bonded and sealed to the surface. This will help prevent any potential issues or damage that may arise from improper installation. In some cases, fiberglass mat tissue may require occasional cleaning to remove any dirt or debris that may accumulate over time. This can be done using mild soap and water, or by following the manufacturer's recommended cleaning instructions. Overall, while fiberglass mat tissue does not require regular maintenance, it is important to address any issues or damages promptly to prevent further deterioration. Regular inspections and necessary repairs should be carried out to ensure the continued performance and longevity of the material.

- Q: Can fiberglass mat tissue be used for wind turbine nacelles?

- Yes, fiberglass mat tissue can be used for wind turbine nacelles. Fiberglass mat tissue is a lightweight and durable material that is commonly used in various industries, including wind energy. It is highly suitable for wind turbine nacelles due to its excellent mechanical properties, such as high strength, stiffness, and resistance to corrosion and fatigue. Additionally, fiberglass mat tissue can be easily molded into complex shapes, making it ideal for fabricating the intricate components of wind turbine nacelles. Overall, using fiberglass mat tissue in wind turbine nacelles helps to enhance their structural integrity, reduce weight, and improve the overall performance and longevity of the turbines.

- Q: Can fiberglass mat tissue be used for making lightweight countertops?

- Yes, fiberglass mat tissue can be used for making lightweight countertops.

- Q: Can fiberglass mat tissue be used for pipe wrapping?

- Yes, fiberglass mat tissue can be used for pipe wrapping. Fiberglass mat tissue is a lightweight and flexible material that is commonly used for reinforcing and protecting various structures, including pipes. It is designed to provide strength and durability to the pipes, making them more resistant to damage and corrosion. The fiberglass mat tissue can be easily wrapped around the pipe, creating a protective layer that helps to prevent leaks and extend the lifespan of the pipe. Additionally, fiberglass mat tissue is also known for its excellent insulation properties, which can help to maintain the temperature of the contents flowing through the pipe. Overall, fiberglass mat tissue is a suitable material for pipe wrapping and is commonly used in various industries for this purpose.

- Q: Can fiberglass mat tissue be used for making furniture?

- No, fiberglass mat tissue is not suitable for making furniture. It is primarily used in composite materials and construction applications, not for furniture manufacturing.

- Q: What is the thermal resistance of fiberglass mat tissue?

- The thermal resistance of fiberglass mat tissue is determined by several factors, including the mat's thickness, fiber density, and the inclusion of additional materials or coatings. In general, fiberglass exhibits low thermal resistance, signifying its excellent heat conductivity. Nevertheless, when employed as insulation, the thickness and density of the fiberglass mat can elevate its thermal resistance, enhancing its ability to reduce heat transfer. It is crucial to acknowledge that precise thermal resistance values may differ based on the product and application, hence it is advisable to consult the manufacturer's specifications for precise information.

- Q: Can fiberglass mat tissue be used for wall insulation?

- No, fiberglass mat tissue is not typically used for wall insulation. It is more commonly used in applications such as reinforcing and adding strength to composite materials like fiberglass panels or laminates. For wall insulation, other materials like fiberglass batts, mineral wool, or foam boards are typically used.

- Q: Can fiberglass mat tissue be used for insulating metal roofs?

- Yes, fiberglass mat tissue can be used for insulating metal roofs. Fiberglass is a popular choice for roof insulation due to its excellent thermal properties and durability. It acts as a barrier to heat transfer, helping to keep the interior of the building cooler in hot weather and warmer in cold weather. Additionally, fiberglass is lightweight and easy to install, making it a practical option for metal roofs. The fiberglass mat tissue is typically applied between the metal roof panels and the building's interior, providing an effective insulation layer.

- Q: How does fiberglass mat tissue compare to fiberglass mesh?

- Fiberglass mat tissue and fiberglass mesh are both commonly used materials in various applications, but they have distinct characteristics and purposes. Fiberglass mat tissue is a lightweight and flexible material that is commonly used in the production of fiberglass-reinforced plastics (FRP). It is made by randomly dispersing glass fibers onto a mesh or non-woven fabric, which is then bonded together with a resin. The resulting material has a smooth surface and a higher tensile strength compared to fiberglass mesh. It provides excellent strength and stiffness, making it ideal for applications that require structural reinforcement, such as automotive parts, boat hulls, and wind turbine blades. On the other hand, fiberglass mesh is a woven fabric made from continuous glass fibers. It has an open mesh structure, which allows for better resin penetration and adhesion. Fiberglass mesh is commonly used for reinforcing surfaces, such as concrete, stucco, and drywall. It provides excellent crack resistance, dimensional stability, and impact resistance. Fiberglass mesh is particularly useful in construction and renovation projects, where it is used to reinforce surfaces and prevent cracking. In summary, fiberglass mat tissue is more suitable for applications that require structural reinforcement and strength, such as in the production of FRP. It provides a smooth surface and offers high tensile strength. Fiberglass mesh, on the other hand, is commonly used for reinforcing surfaces and preventing cracking in construction projects. It has an open mesh structure, allowing for better resin penetration and adhesion. Ultimately, the choice between fiberglass mat tissue and fiberglass mesh depends on the specific requirements of the application.

Send your message to us

Fiberglass Mat Tissue E Glass Fiber Woven Roving for Boat Production

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 2000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords