Fiberglass Mat Tissue Woven Roving for Hand Lay-Up

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

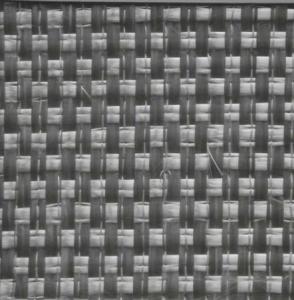

Structure of woven roving Description

E-Glass Woven Roving are bidirectional fabric made by interweaving direct rovings

E-Glass Woven Roving are compatible with unsaturated polyester, vinyl eater, epoxy and phenolic resins.

E-Glass Woven Rovings are a high-perfprmance reinforcement widely used in hand lay up and robot processes to manufacture boats, vessels, plane and automotive parts, furniture and sports facilities

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

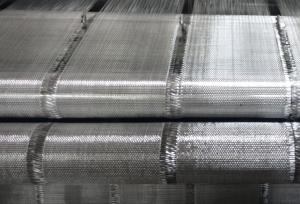

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

3. What is your MOQ?

Our MOQ is one pallet.

4. Can you provide sample?

Yes, samples are in stock. we can offer free sample for you.

5. Payment terms?

We can accept L/C, T/T etc.

6. Do you offer OEM service?

Yes, we can print customers’ logo on the packaging;

And the size and specification can be produced and design according to your demand.

7. What is the Production Lead Time?

1 *40HQ each day.

- Q: Can fiberglass mat tissue be used for acoustic insulation?

- Yes, fiberglass mat tissue can be used for acoustic insulation. It is a commonly used material for soundproofing due to its ability to absorb and dampen sound waves. Its high density and fibrous structure make it effective in reducing noise and improving acoustic performance in buildings, vehicles, and other applications.

- Q: How does the density of fiberglass mat tissue impact its performance?

- The density of fiberglass mat tissue significantly affects its performance. Fiberglass mat tissue is a nonwoven material composed of randomly dispersed glass fibers held together by a binder. The density of the tissue refers to the amount of fibers present in a given volume of the material. A higher density of fiberglass mat tissue generally results in improved mechanical properties and performance. The increased density means that there are more glass fibers per unit volume, leading to enhanced strength, stiffness, and durability. This makes the material more resistant to tearing, puncturing, and abrasion, which is particularly important in applications where the tissue is exposed to harsh conditions or heavy loads. Moreover, a higher-density fiberglass mat tissue offers better thermal insulation properties. The increased fiber content allows for better heat resistance, making it suitable for applications that require thermal protection, such as insulation boards or fireproofing materials. On the other hand, a lower density of fiberglass mat tissue may provide advantages in certain applications. Lower-density tissues are generally more flexible and have better conformability, allowing them to easily adapt to irregular surfaces or complex shapes. This makes them suitable for applications where flexibility or conformability is a primary requirement, such as in automotive or aerospace industries. Overall, the density of fiberglass mat tissue plays a crucial role in determining its performance characteristics. Whether a higher or lower density is preferred depends on the specific application requirements, considering factors such as strength, stiffness, durability, thermal insulation, flexibility, and conformability.

- Q: Does fiberglass mat tissue require any special surface treatments before application?

- Special surface treatments are necessary before applying fiberglass mat tissue in order to ensure proper adhesion and bonding with the substrate. Applying a primer or bonding agent is a common treatment that enhances the bond strength between the fiberglass mat tissue and the substrate. Typically, the primer or bonding agent is applied to the substrate and allowed to dry before applying the fiberglass mat tissue. Another treatment involves removing any loose or flaking material from the substrate's surface. This can be achieved through mechanical methods like sanding or grinding, or by using a chemical treatment to dissolve or eliminate unwanted material. This step is crucial to establish a clean and smooth surface for the fiberglass mat tissue to adhere to. In certain cases, it may be necessary to roughen or etch the substrate's surface to provide a better bonding surface for the fiberglass mat tissue. The method used for roughening or etching depends on the type of substrate being used and can involve abrasives or chemical etching agents. The specific surface treatment required for fiberglass mat tissue depends on factors such as the type of substrate, desired bond strength, and application method. Following the manufacturer's instructions and recommendations for surface preparation is essential to achieve a successful application and long-lasting bond.

- Q: What is the delamination strength of fiberglass mat tissue?

- The delamination strength of fiberglass mat tissue refers to its ability to resist the separation or detachment of layers within the material. This strength is dependent on various factors such as the quality of the resin used, the thickness and density of the mat, and the manufacturing process. Fiberglass mat tissue is typically designed to have a high delamination strength to ensure its durability and structural integrity. The mat is composed of multiple layers of glass fibers held together by a binder or resin. The bonding between these layers is crucial in preventing delamination. The delamination strength of fiberglass mat tissue can be determined through various testing methods, such as the peel test, where the force required to separate the layers is measured. This test provides valuable information about the adhesive strength between the layers and helps in assessing the overall quality of the material. The delamination strength can vary depending on the specific application and requirements. For example, fiberglass mat tissue used in construction or automotive industries may have different delamination strength specifications compared to those used in marine or aerospace applications. Manufacturers typically provide technical data or specifications indicating the delamination strength of their fiberglass mat tissue products. It is important to note that the delamination strength of fiberglass mat tissue can be influenced by external factors such as exposure to extreme temperatures, moisture, or chemical substances. Therefore, proper installation, maintenance, and adherence to recommended usage guidelines are essential to maintaining the desired delamination strength and overall performance of the material.

- Q: Can fiberglass mat tissue be used for composite panel manufacturing?

- Yes, fiberglass mat tissue can be used for composite panel manufacturing. It is a common material choice for reinforcing composite panels due to its high strength, durability, and compatibility with various resin systems. The fiberglass mat tissue provides structural integrity and improved strength-to-weight ratio to the composite panel, making it suitable for a wide range of applications.

- Q: Can fiberglass mat tissue be used for wall insulation?

- No, fiberglass mat tissue is not typically used for wall insulation. It is more commonly used in applications such as reinforcing and adding strength to composite materials like fiberglass panels or laminates. For wall insulation, other materials like fiberglass batts, mineral wool, or foam boards are typically used.

- Q: Can fiberglass mat tissue be used for insulating metal buildings?

- Yes, fiberglass mat tissue can be used for insulating metal buildings. Fiberglass mat tissue is a lightweight and flexible material that can provide effective thermal insulation for metal structures. It is commonly used as a layer between the metal panels and the interior of the building to prevent heat transfer and improve energy efficiency. Additionally, fiberglass mat tissue is resistant to moisture and does not promote the growth of mold or mildew, making it an ideal choice for insulating metal buildings. However, it is important to ensure proper installation to maximize its insulation properties and prevent any gaps or air leaks.

- Q: Can fiberglass mat tissue be used for repairing automotive parts?

- Yes, fiberglass mat tissue can be used for repairing automotive parts. Fiberglass mat tissue is a versatile material that is commonly used for reinforcing and repairing various surfaces, including automotive parts. It is particularly useful for repairing parts that are made of fiberglass, such as car bodies and panels. Fiberglass mat tissue is a thin and flexible material that is made up of randomly oriented fiberglass strands. It is designed to be easily molded and shaped to fit the contours of the damaged automotive part. The mat tissue is typically applied with a resin, such as polyester or epoxy, which binds the fibers together and creates a strong and durable repair. When used for automotive repairs, fiberglass mat tissue provides several benefits. Firstly, it is lightweight, which is important for maintaining the overall weight and balance of the vehicle. Additionally, it is resistant to corrosion and can withstand exposure to various weather conditions, making it suitable for all types of automotive repairs. Moreover, fiberglass mat tissue is known for its high tensile strength, which means that it can withstand the stresses and strains that automotive parts may experience during normal use. This makes it an ideal choice for repairing damaged or weakened areas, such as cracks, holes, or dents in car bodies or panels. In conclusion, fiberglass mat tissue can be effectively used for repairing automotive parts, especially those made of fiberglass. Its versatility, lightweight nature, resistance to corrosion, and high tensile strength make it an excellent choice for restoring the structural integrity and appearance of damaged automotive parts.

- Q: Is fiberglass mat tissue suitable for railway rolling stock?

- Yes, fiberglass mat tissue is suitable for railway rolling stock. It offers excellent strength, durability, and fire resistance properties, making it a suitable material for various applications in the railway industry. Additionally, fiberglass mat tissue is lightweight, corrosion-resistant, and can be easily molded and shaped according to specific design requirements, making it an ideal choice for railway rolling stock components.

- Q: Is fiberglass mat tissue suitable for aerospace repairs?

- Yes, fiberglass mat tissue is suitable for aerospace repairs. It is a lightweight and strong material that can be used to reinforce and repair aerospace structures. It provides excellent strength-to-weight ratio and has good resistance to corrosion and heat. Additionally, it is easy to work with and can be molded into various shapes to fit the specific repair requirements.

Send your message to us

Fiberglass Mat Tissue Woven Roving for Hand Lay-Up

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 3000 kg

- Supply Capability:

- 50000 kg/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords