Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 400g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

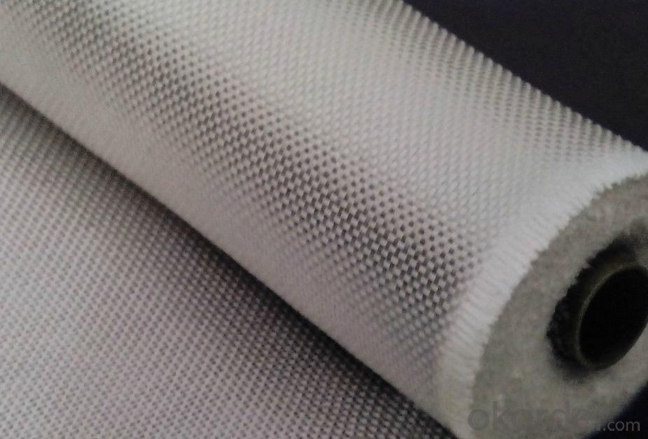

Structure of woven roving Description

Glass woven rovings are bidirectional fabric by direct rovings in plain weave pattern. They are applicable for hand lay-up, winding and compress molding process, suitable for manufacturing tank, boat, automobile parts and other FRP products.

1,high strenth,corosion and resistence

2,consistent thickness,no fuzz

3,rapid impregnating

Main Features of the woven roving

1)Drapes well to suit the surface of intricate moulds

2)Fast wet-through and wet out

3)Easy handing and better appearance of the composite parts

4)Compatible with Unsaturated polyester resin

5)Very high laminate strength properties

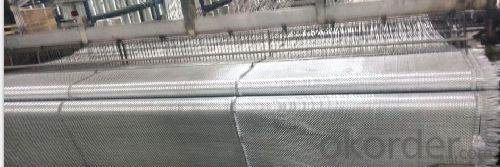

Woven roving Images

Woven roving Specification:

Normal type | EWR800 | EWR400 | EWR300 | EWR500 | EWR600 |

Thickness (mm) | 0.8 | 0.4 | 0.3 | 0.5 | 0.6 |

Density(warpxweft) (end/cm) | 1.8x1.5+/-10% | 3.6x3.2+/-10% | 4.6x4.1+/-10% | 2.2X2.0+/-10% | 2.6X2.4+/-10% |

Tex (warpxweft) | 2400x2400 | 600X600 | 300x400 | 1200x1200 | 1200X1200 |

Moisture content(%) | <0.2% | <0.2% | <0.2% | <0.2% | <0.2% |

Loss on ignition(%) | 0.4 – 0.8 | 0.4-0.8 | 0.4-0.8 | 0.4-08 | 0.4-0.8 |

Width(cm) | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 | 125+/-1 |

Weight (g/m2) | 816+/-41 | 408+/-32 | 300+/-15 | 500+/-25 | 600+/-30 |

Weight per roll(kg) | 45 | 46 | 50 | 45 | 45 |

Glass | E-glass | E-glass | E-glass | E-glass | E-glass |

FAQ of woven roving:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

Application of Fiberglass Woven Roving:

a) boats ,vessels ,plane

b) automotive parts ,furniture and sports facilities

c) resins system,such as polyeser,vinylester and epoxy resins

- Q: How is fiberglass mat tissue used in the production of windshields?

- Fiberglass mat tissue is used in the production of windshields as a reinforcement material. It is sandwiched between layers of glass to increase the strength and durability of the windshield. This tissue provides added resistance to impacts, helps prevent cracks from spreading, and improves overall structural integrity.

- Q: Does fiberglass mat tissue absorb water?

- Yes, fiberglass mat tissue does absorb water.

- Q: What is fiberglass mat tissue?

- Fiberglass mat tissue is a type of non-woven material made from glass fibers that are randomly oriented and bonded together with a binder. It is commonly used in various industries, including construction, automotive, and aerospace. The main purpose of fiberglass mat tissue is to provide strength, durability, and reinforcement to composite materials. It acts as a supporting layer between the resin and the glass fibers, helping to distribute stress and improve the overall mechanical properties of the final product. Fiberglass mat tissue has several advantages over other materials. It is lightweight, flexible, and easy to handle, making it ideal for applications that require complex shapes or curved surfaces. It also has excellent resistance to chemicals, moisture, and temperature changes, ensuring its longevity in harsh environments. In construction, fiberglass mat tissue is often used in the production of roofing materials, wall panels, and insulation boards. Its high strength-to-weight ratio makes it a popular choice for reinforcing concrete structures, such as bridges and buildings. In the automotive industry, fiberglass mat tissue is used in the manufacturing of car parts, such as body panels, bumpers, and interior components. It can enhance the structural integrity of these parts, making them more resistant to impacts and vibrations. In the aerospace industry, fiberglass mat tissue is employed in the production of aircraft components, such as wings, fuselages, and interiors. Its lightweight nature contributes to fuel efficiency and overall weight reduction, while still maintaining the necessary strength for safe flight. Overall, fiberglass mat tissue is a versatile and reliable material that plays a crucial role in enhancing the performance, durability, and safety of various products in different industries. Its unique properties make it an indispensable component in the production of composite materials.

- Q: What are the different weights available for fiberglass mat tissue?

- The different weights available for fiberglass mat tissue range from 20 grams per square meter (gsm) to 100 gsm.

- Q: Can fiberglass mat tissue be used for insulating windows?

- Certainly! Insulating windows is possible with the utilization of fiberglass mat tissue. This lightweight and adaptable material is frequently employed for insulation objectives. With its commendable thermal resistance, it effectively diminishes the escape or entry of heat through windows. By simply affixing a layer of fiberglass mat tissue onto the window surface, it greatly enhances the window's insulation capabilities, thereby reducing drafts and heat transfer. Moreover, this multifunctional fiberglass mat tissue also effectively minimizes noise transmission, rendering it a versatile choice for both thermal and acoustic insulation purposes.

- Q: Can fiberglass mat tissue be used for repairing fiberglass boats?

- Yes, fiberglass mat tissue can be used for repairing fiberglass boats. Fiberglass mat tissue is a versatile material that is commonly used in repairing and reinforcing fiberglass structures, including boats. It is designed to provide strength and durability, making it an ideal choice for patching holes, cracks, or damaged areas in fiberglass boat hulls. The mat tissue is typically layered with resin to form a solid and stable repair, ensuring that the boat remains structurally sound. Additionally, fiberglass mat tissue is easy to work with and can be cut to the desired size and shape, making it suitable for various repair applications on fiberglass boats.

- Q: What are the different finishing options available for fiberglass mat tissue?

- Some of the different finishing options available for fiberglass mat tissue include: resin coating, heat treatment, laminating, and surface texturing. These options can enhance the strength, durability, and appearance of the fiberglass mat tissue based on specific requirements and applications.

- Q: Can fiberglass mat tissue be used for acoustic panels?

- Yes, fiberglass mat tissue can be used for acoustic panels. It is commonly used as a core material in acoustic panels due to its excellent sound absorption properties. The fibers in the tissue help to dissipate sound energy and reduce echo and reverberation in a room.

- Q: Is fiberglass mat tissue suitable for railway rolling stock?

- Yes, fiberglass mat tissue is suitable for railway rolling stock. Fiberglass mat tissue is a lightweight and durable material that is commonly used in the construction industry for various applications, including in the manufacturing of railway rolling stock. It offers excellent mechanical strength and resistance to corrosion, making it ideal for use in the harsh and demanding environments that railway rolling stock typically operates in. Additionally, fiberglass mat tissue has good thermal insulation properties, which can help to improve the energy efficiency of the rolling stock. Overall, fiberglass mat tissue is a suitable and reliable choice for the construction and maintenance of railway rolling stock.

- Q: Can fiberglass mat tissue be used for repairing fiberglass truck beds?

- Yes, fiberglass mat tissue can be used for repairing fiberglass truck beds. It is commonly used in such repairs due to its strength, durability, and ability to bond well with the existing fiberglass surface.

Send your message to us

Fiberglass Mat Tissue E-Glass Fiberglass Woven Roving, 400g, 1040mm

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords