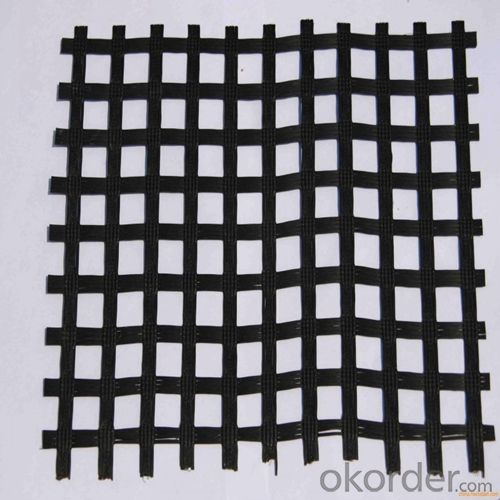

Non Woven Geotextile Fabric for Fiberglass Geogrid in Mining and Tunnel Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description

Geogrid allows assembling within the temperature range from -40°C to +60°C. The material is neutral to aggressive environments and ecologically safe. Laying does not require additional machinery. In fold position geogrid does not take much place.

Type:

Geogrids

Place of Origin:

Anhui, China (Mainland)

Brand Name:

CMAX

Model Number:

Biaxial

Material:

Fiberglass

Tensile strength:

100kn

Production function

1.It can be applied in all kinds of roads,airports to enhance the roadbed;

2.It can be applied in a large car park and terminal freight yard,etc. to strengthen the foundations of a permanent load;

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

FAQ:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

- Q: Where is the geotextile

- Essence is also the beauty of the latest brand of science and technology crystallization of the product

- Q: How do geotextiles improve the performance of railway tracks?

- Geotextiles improve the performance of railway tracks by providing a stable and well-drained base for the tracks. They prevent the contamination of subgrade soil, control soil erosion, and enhance load distribution. Additionally, geotextiles reduce the formation of track deformations and increase the overall durability and lifespan of the railway tracks.

- Q: Can geotextiles be used in landfill construction?

- Yes, geotextiles can be used in landfill construction. They are often used as a barrier or liner material to separate the waste from the underlying soil and prevent leachate from contaminating the surrounding environment. Geotextiles can also be used to reinforce the landfill slopes and prevent erosion.

- Q: what is the purpose of geotextile on gabion walls.?

- Geotextiles are fabrics associated with soil, earth or rocks. Gabions were earth filled barricades meant to halt enemy fire during battle. I'm guessing geotextiles on gabion walls more effectively hold back the earth or filler. They might have well suited permeability or retentive qualities for gabions. There are a few other definitions for gabions. But this is the militaristic definition. Gabions are also used in dams and such. In this case, geotxtiles might have good properties for being submerged in water and still retaining whats inside the gabions.

- Q: What are the considerations for geotextile selection in shoreline erosion control?

- When selecting geotextiles for shoreline erosion control, several considerations need to be taken into account. These include the type of shoreline, the severity of erosion, the desired lifespan of the solution, the presence of waves or currents, the sediment type, and the environmental conditions. Factors such as geotextile strength, permeability, durability, and resistance to UV degradation and chemical exposure should also be considered to ensure an effective and long-lasting solution for shoreline erosion control.

- Q: What are the different methods of installing geotextiles?

- There are several different methods of installing geotextiles, including direct placement, trenching, and stapling. Direct placement involves unrolling the geotextile fabric directly onto the ground surface and securing it with stakes or pins. Trenching involves digging a narrow trench along the desired location and placing the geotextile fabric inside the trench before backfilling it. Stapling involves using staples or nails to secure the geotextile fabric to the ground or other surfaces. The specific method used depends on the project requirements and the intended function of the geotextiles.

- Q: What are the environmental benefits of using geotextiles?

- Geotextiles offer several environmental benefits, such as erosion control by stabilizing soil and preventing sediment runoff, enhancing water filtration and drainage systems, reducing the need for chemical herbicides and pesticides, and promoting the growth of vegetation. Additionally, they can help in the restoration and protection of ecosystems, reduce construction waste by extending the lifespan of infrastructure, and minimize the use of non-renewable materials like aggregates.

- Q: Geotextile drainage network and geotextile how to heat stick

- Geotextile and geotextile crimp part of the use of sewing or hot air welding. Hot air welding is the connection method of filament geotextile, that is, with the hot air gun on the connection of two pieces of cloth instantaneous high temperature heating, so that part of the molten state, and immediately use a certain external force to make it firmly together. In the case of wet (rain and snow) weather can not be hot adhesive connection, geotextile should take another method of a suture connection method, that is, with a dedicated sewing machine for two-wire suture connection, and the use of anti-chemical UV suture.

- Q: Google for a long time only geotextile ads! The The Do not know geotextile, drainage board such materials, in what kind of shop which has to sell? Because the building materials market to a circle, people did not sell this thing more

- Retail, then, to the local hardware and electrical city to see. Manufacturers of drainage board geotextile

- Q: Can geotextiles be used in the protection of embankments?

- Yes, geotextiles can be used in the protection of embankments. Geotextiles are permeable textile materials that are placed in the soil to enhance its engineering properties. When used in embankments, geotextiles help in soil stabilization, erosion control, and drainage, thereby protecting the embankment from erosion, excessive water flow, and potential damage.

Send your message to us

Non Woven Geotextile Fabric for Fiberglass Geogrid in Mining and Tunnel Reinforcement

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords