8oz Non Woven Geotextile for Fiberglass Geogrid Reinforcement and Separation in Dam and River

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

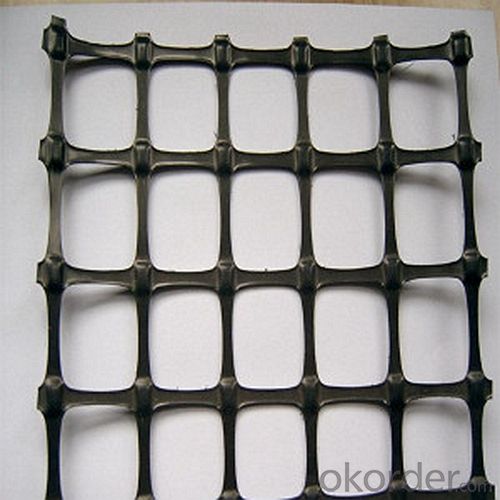

Fiberglass Geogrid with CE Certificate

We can produce fiberglass geogrid with tensile strength 30x30kn--300x300kn/m. mesh size

can be 25.4x25.4mm or 12.7x12.7m ,50x50mm.

ITEM

50KNX50KN/M

100KNX100KN/M

MESH SIZE

25.4X25.4MM

25.4X25.4MM

TENSILE STRENGTH

WARP 50KN/M

WARP 100KN/M

WEFT 50KN/M

WEFT 100KN/M

WEIGHT

300G/SQM

500G/SQM

ELONGATION AT BREAK

3%

3%

TENSILE STRENGTH IN KNOT

5KN/M

10KN/M

WIDTH:

1--6M

1--6M

Our Service

Quality assurance

1.On a regular basis or as per your request,we entrust national testing agencies to conduct quality inspections

2. Strictly in accordance with the ISO9001-2008 international quality system standard,we monitor and manage the whole process throughout production,quality testing,and measurement to ensure product quality

3. For quality-related construction delay or substandard construction(except for damage or losses due to customer’s responsibility or irresistible natural disasters),we have refunding,replacement,and repair services.We will respond to customers’ feedbacks on quality issues within 24 hours.

FQR:

Q: What kind of payments does jenor support?

A: T/T, L/C, Cash are accepted.

Q: Do you charge for the samples?

A: Accordeing to our company policy, the samples are free, we only charge the freight fee. And we will return the freight fee during the next order.

Q: Can you produce according to customers' design?

A: Sure, we are professional manufacturer, OEM and ODM are both welcome.

Q: Do you have other products?

A: Yes, please check the pictures:

Packaging & Shipping

Packing: PLASTIC FILM INSIDE, AND WOVEN BAG OUTSIDE

Shipping: About 15 days after receipt the deposit

- Q: What are the factors to consider when designing with geotextiles?

- When designing with geotextiles, several factors need to be considered. These include the type and quality of the geotextile material, the specific application and project requirements, the site conditions and soil properties, the expected loads and stresses, the installation and maintenance procedures, and the long-term performance and durability of the geotextile. Additionally, factors such as cost-effectiveness, environmental impact, and regulatory compliance should also be taken into account during the design process.

- Q: Road Central isolation belt (5 m wide) Drainage No design Waterproof geotextile laying and gravel blind ditch, are design flaws?

- Should be it, the general design will have this. If you need to contact me, see the information

- Q: What are the specifications for geotextiles in erosion control projects?

- The specifications for geotextiles in erosion control projects typically include the material type, weight, thickness, permeability, and tensile strength. Additionally, the specifications may outline requirements for installation methods, durability, UV resistance, and longevity. These specifications are crucial to ensure that geotextiles effectively mitigate erosion and provide long-lasting erosion control solutions.

- Q: How do geotextiles help with soil confinement in erosion control block walls?

- Geotextiles play a crucial role in soil confinement within erosion control block walls by acting as a filter and separator. They prevent soil particles from washing out while allowing water to drain through, thereby reducing hydrostatic pressure and the risk of wall failure. Additionally, geotextiles enhance the overall stability and longevity of the wall by providing reinforcement and preventing soil erosion.

- Q: Geotextile business how to run

- Geotextile as a geotextile material, engineering applications have been very popular, the market competition is also very intense. Profits have been very low Bulk geotextile transactions are mainly ordered in the form of tender, so please pay attention to bidding information, I wish you success.

- Q: How do geotextiles improve the performance of tunnels?

- Geotextiles improve the performance of tunnels by providing reinforcement and stabilization to the surrounding soil, preventing soil erosion and subsidence. They also act as a barrier to prevent the migration of fine particles, improving the overall durability and longevity of the tunnel structure.

- Q: Can geotextiles be used in road shoulder stabilization?

- Yes, geotextiles can be used in road shoulder stabilization. Geotextiles are commonly employed in road construction and maintenance projects to provide soil stabilization, prevent erosion, and improve drainage. By placing geotextiles in road shoulders, they can help reinforce the soil, increase load-bearing capacity, and reduce the risk of shoulder erosion, ultimately enhancing the stability and longevity of the road.

- Q: Can China produce polypropylene filament geotextiles? Google knows

- Yes, I am professional production, wish smooth

- Q: Can geotextiles be used in the protection of underground tanks?

- Yes, geotextiles can be used in the protection of underground tanks. Geotextiles are often used as a protective barrier between the tank and the surrounding soil to prevent erosion, provide stability, and improve the longevity of the tank. They can also help in filtering out sediment and preventing clogging of tanks, ensuring their efficient operation.

- Q: Can geotextiles be used in erosion control on steep slopes?

- Yes, geotextiles can be used in erosion control on steep slopes. Geotextiles are specially designed fabrics that are used to stabilize soil and prevent erosion. They can be installed on steep slopes to reinforce the soil, reduce water flow, and promote vegetation growth, all of which help to prevent erosion and maintain slope stability.

Send your message to us

8oz Non Woven Geotextile for Fiberglass Geogrid Reinforcement and Separation in Dam and River

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m²

- Supply Capability:

- 1000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords