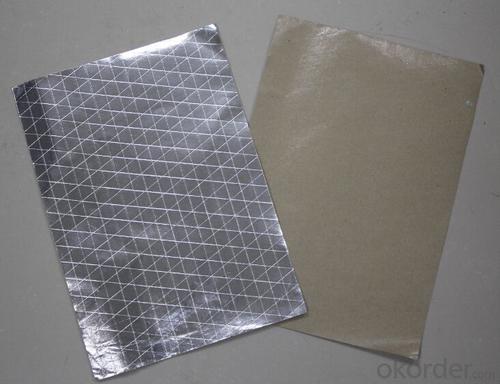

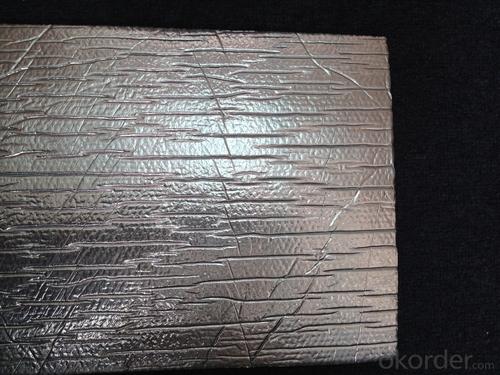

Fiberglass Facing Flexible Ducts Bubble Foil Glasswool Green Energy Sol

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Application:

1,Building Thermal Insulation Material

(1),Roof,Underlay,Under Concrete & floor Insulation;

(2),Attic,Crawl Space,Stud Wall ,Metal Frame Building Insulation.

2,Wrapping

(1),Protective coatings of ventilating pipe,HVAC Duct & Pipe;

(2),Shells of air conditioner and water heater.

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

Feature:

1), Waterproof, heavy duty, clean, light, flexible, non-absorbent surface

2), Fire resistant & antiglare

3), Recyclable, environmentally friendly

4), Effective in extreme temperatures both hot and cold

5), Easily install, cut, stapled, nailed or glued into place

6), Safe to handle with no special clothing or breathing Equipment

- Q: What is the chemical stability of black fiberglass tissue, and how does it react to various chemicals?

- <p>Black fiberglass tissue, which is a type of composite material made from glass fibers and a resin matrix, typically exhibits good chemical stability. It is resistant to many chemicals, including alkalis, acids, and salts, making it suitable for various industrial applications. However, it may not be as stable against strong acids or bases over extended periods. The stability can also be influenced by the specific type of resin used in the fiberglass, with some resins offering better resistance to certain chemicals than others. It's important to consult the material data sheet for specific information on chemical resistance for the black fiberglass tissue in question.</p>

- Q: What are the benefits of using fiberglass facing?

- Fiberglass facing offers numerous advantages in various applications. Firstly, its exceptional strength and durability make it highly resistant to cracking, warping, and other forms of damage. This quality makes it ideal for construction and structural purposes, where strength and longevity are crucial. Furthermore, fiberglass facing provides excellent thermal insulation properties. With its low thermal conductivity, it effectively prevents heat transfer and maintains a consistent temperature in both hot and cold environments. Consequently, it is widely used in insulation for buildings, HVAC systems, and other energy-efficient applications. Another benefit of fiberglass facing is its resistance to moisture and corrosion. Since it is non-porous and does not absorb water, it is highly resistant to mold, mildew, and rot. This makes it a suitable choice for damp or humid environments, including bathrooms and kitchens. Moreover, fiberglass facing is lightweight and easy to handle, making it convenient to install and transport. It can be easily cut and shaped to fit various surfaces and configurations, allowing for flexibility in design and installation. Its lightweight nature also reduces strain on supporting structures, making it cost-effective for construction projects. Lastly, fiberglass facing comes in a wide range of sizes, thicknesses, and finishes, allowing customization to meet specific project requirements. It can be coated or laminated with different materials to enhance performance, such as adding a vapor barrier or reflective surface. This versatility makes it suitable for various applications across industries, from construction to transportation. In summary, the advantages of fiberglass facing include its strength and durability, thermal insulation properties, resistance to moisture and corrosion, lightweight nature, and customization options. These qualities make it a popular choice in industries where these characteristics are highly valued.

- Q: Is it possible to utilize black fiberglass tissue for crafting decorative items?

- <p>Yes, black fiberglass tissue can be used to create decorative elements. It is known for its strength, durability, and flexibility, making it an ideal material for various artistic and design applications. Fiberglass can be molded into different shapes and forms, and its black color can add a sleek, modern touch to any decor. It's often used in combination with other materials to create unique and eye-catching designs, from wall art to furniture accents. However, it's important to handle fiberglass with care due to its potential health risks and to ensure proper ventilation during any cutting or shaping processes.</p>

- Q: This question asks for a comparison of different types of black fiberglass tissues, focusing on their unique characteristics and applications.

- <p>Black fiberglass tissues, also known as black glass fabrics, can vary based on their weave patterns, fiber types, and treatment processes. Some common types include plain weave, twill weave, and satin weave, each offering different strengths and flexibility. The fiber itself can be E-glass, S-glass, or other types, impacting the fabric's strength and heat resistance. Surface treatments like resin or silicone can affect the fabric's surface properties, making it more suitable for specific applications such as electrical insulation, thermal protection, or reinforcement in composite materials. Each type is chosen based on the required mechanical properties, chemical resistance, and environmental conditions it will face.</p>

- Q: Is it possible to utilize black fiberglass tissue in the creation of garments?

- <p>While it is technically possible to use black fiberglass tissue for clothing, it is not a common practice due to its rigidity and lack of flexibility. Fiberglass is typically used in construction and insulation applications. For clothing, materials that are soft, breathable, and flexible are preferred. If you're looking for a durable fabric, consider alternatives like Kevlar or other synthetic fibers designed for clothing.</p>

- Q: This question asks for the most effective method to clean black fiberglass material.

- <p>The best way to clean black fiberglass tissue is by using a gentle cleaning solution and soft bristled brush. Start by mixing a mild detergent with warm water. Apply the solution to the fiberglass and gently scrub with a soft brush to avoid scratching. Rinse thoroughly with clean water and dry with a soft cloth to prevent water spots. For stubborn stains, consider using a fiberglass-specific cleaning product, but always test on a small area first to ensure it doesn't discolor the material. Regular cleaning will help maintain the appearance and longevity of black fiberglass tissue.</p>

- Q: Is it possible to recycle black fiberglass paper?

- <p>Yes, black fiberglass paper can be recycled, but the process may vary depending on local recycling facilities and their capabilities. Fiberglass paper is a composite material made from glass fibers and a resin binder, which can be challenging to recycle due to its composite nature. Some recycling centers may accept it, while others may not. It's essential to check with your local waste management or recycling facility to determine if they can process black fiberglass paper. If they cannot, you may need to find a specialized recycling service that handles composite materials.</p>

- Q: This question asks about the uses of black fiberglass tissue across different sectors.

- <p>Black fiberglass tissue, also known as black glass fabric, is widely used in various industries due to its high strength, heat resistance, and electrical insulation properties. In the construction industry, it is used for reinforcing materials in composites and as a base for flooring. In the automotive sector, it is utilized for brake linings and heat shields. The electronics industry employs it for printed circuit boards and insulation. It is also used in aerospace for heat-resistant components and in the marine industry for hull reinforcement. Additionally, it finds applications in the production of sports equipment, such as surfboards and kayaks, and in the creation of high-temperature resistant fabrics for industrial settings.</p>

- Q: China's glass fiber product code is what?

- The code name of the song, for example, the order: ???????????? C C 8-36 × 2 × 3 S 110 ???????????????????????????????????? Twist (twist / m) ???????????????????????????????????? Twist ???????????????????????????????????? And twist the number of shares ???????????????????????????????????? Number of shares released ???????????????????????????????????? Original yarn density (g / 1000m) ???????????????????????????????????? Single fiber nominal diameter (m?) ???????????????????????????????????? Continuous glass fiber ???????????????????????????????????? Alkaline glass fiber Description: ① twist to S that the right twist, Z said left twist:

- Q: This question asks about the distinctions among various types of glass fiber paper, which are materials made from thin strands of glass.

- <p>Different types of glass fiber paper are distinguished by their composition, manufacturing processes, and applications. E-glass is the most common and is used for general purposes due to its good electrical insulation properties. S-glass, known for its high strength, is used in applications requiring mechanical strength, such as in aircraft and sports equipment. C-glass is resistant to chemical corrosion and is used in environments with harsh chemicals. A-glass, or alumino-borosilicate glass, is used for applications requiring high temperature resistance. Lastly, D-glass is designed for low dielectric applications, making it suitable for electronics. Each type has unique properties that make it suitable for specific industries and applications.</p>

Send your message to us

Fiberglass Facing Flexible Ducts Bubble Foil Glasswool Green Energy Sol

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords