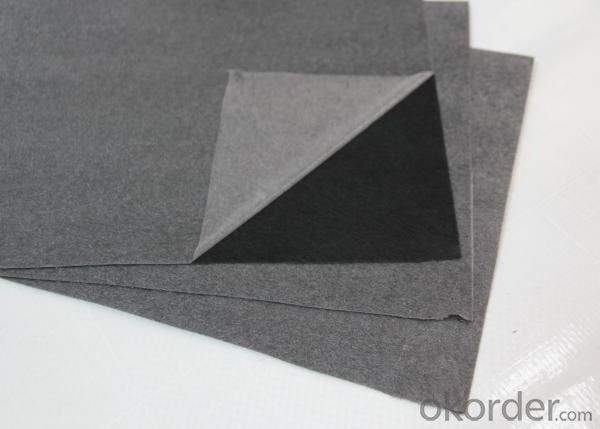

Fiberglass Facing Black Fiberglass Cloth BFC-001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 50000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specification of Black Fiberglass Cloth BFC-001

|

Specification | ||

|

ITEM |

UNIT |

VALUE |

|

Weight of the tissue |

g/m2 |

65 |

|

Weight of the Finished Product |

g/m2 |

65 +25 PE |

|

Thickness |

mm |

0.42 |

|

Fusion Temperature |

℃ |

≦130 |

|

Oxygen Index Number |

% |

≥32 |

|

Tensile Strength MD |

n/5cm |

125 |

|

Tensile Strength CMD |

n/5cm |

105 |

SIZE:

Width: 0.6m---1.3m

Length: 100m-1000m

Core I.D.: 3"(76mm ±1)

Based on order, special sizes are also available.

MSDS:No harm for body and environment, non-volatile product.

Remarks:

1. The data above are typical results and subject to change without notice.

2. Tolerance: Weight and Thickness: ±10%; Width: ±3mm; Length: ±0.5%.

3. The products should be stored at room temperature, kept from wet and kept away heat source.

4. Good appearance without stain, oxidation, mildew.

5. The users should take test and do trial-application on the above products before coming into application so as to witness and ensure suitability for their special purpose and technique.

2. Application of Black Fiberglass Cloth BFC-001

Fiberglass facing is good at fireproof, mildew resistant, damp proof and strong air permeability. After laminated with glass wool or rock wool, the physical properties is excellent such as hat preservation, noise elimination, fire retardant, extinction,etc.

3. Packaging & Delivery of Black Fiberglass Cloth BFC-001

Depends on the clients' requirements and the production conditions.

- Q: This question asks about the positive environmental impacts of incorporating glass fiber paper in construction.

- <p>The use of glass fiber paper in construction projects offers several environmental benefits. It is a sustainable material that can be recycled, reducing waste in landfills. It has excellent insulation properties, which can lower energy consumption in buildings and reduce greenhouse gas emissions. Glass fiber paper is also resistant to moisture and rot, which means it doesn't require treatments with harmful chemicals, thus reducing environmental pollution. Additionally, it is lightweight and strong, reducing the amount of material needed for construction and lowering transportation emissions. Overall, its use promotes a more eco-friendly and sustainable construction industry.</p>

- Q: This question asks if there is any difference between black fiberglass tissues that are domestically produced and those that are imported.

- <p>Yes, there can be differences between domestic and imported black fiberglass tissues. These differences may include quality standards, manufacturing processes, material composition, and cost. Domestic products are often more readily available and may be subject to local regulations and standards, while imported products might have different certifications or comply with international standards. Additionally, the cost can vary due to factors like transportation, import duties, and market demand. It's important to consider the specific application and requirements when choosing between domestic and imported black fiberglass tissues.</p>

- Q: This question asks about the advantages of black fiberglass tissue in terms of environmental protection compared to other materials.

- <p>The use of black fiberglass tissue offers several environmental benefits. It is a lightweight material that can reduce the energy consumption required for transportation. Additionally, it has excellent thermal insulation properties, which can lead to energy savings in buildings and reduce greenhouse gas emissions. Black fiberglass tissue is also resistant to moisture and rot, reducing the need for replacement and disposal, thereby decreasing waste. Furthermore, it is made from glass, a material that can be recycled, contributing to a circular economy and reducing the environmental impact of material extraction and production.</p>

- Q: What is the tensile strength of black fiberglass tissue?

- <p>The tensile strength of black fiberglass tissue can vary depending on the specific type and manufacturing process. Generally, it ranges from 500 to 3000 MPa (or 72,500 to 435,000 psi). This high tensile strength makes it suitable for applications requiring high strength-to-weight ratios, such as in construction, automotive, and aerospace industries. It's important to note that the exact tensile strength should be obtained from the manufacturer's specifications for the specific product in question.</p>

- Q: Is the use of black fiberglass scraps considered safe in construction projects?

- <p>The use of black fiberglass scraps in construction work is generally not recommended due to safety and quality concerns. Black fiberglass scraps may contain impurities and inconsistencies that can compromise the structural integrity of the construction. Additionally, they can pose health risks due to the inhalation of fiberglass particles, which can cause respiratory issues. It's crucial to use high-quality, undamaged materials that meet safety standards to ensure the safety of both the construction workers and the longevity of the construction project.</p>

- Q: Are there any black fiberglass tissues specifically formulated for individuals with sensitive skin?

- <p>Yes, there are specific types of black fiberglass tissues designed for sensitive skin. These products are often made with gentler materials and are hypoallergenic to minimize irritation. They may also be fragrance-free and dermatologically tested to ensure they are suitable for those with sensitive skin. It's important to look for products that are labeled as suitable for sensitive skin when choosing black fiberglass tissues.</p>

- Q: This question seeks to understand the distinctions between fiberglass and other non-woven materials.

- <p>Fiberglass is a type of composite material made from fine fibers of glass, which are often combined with a resin to form a strong, lightweight material. It's known for its high strength-to-weight ratio, resistance to corrosion, and electrical insulation properties. Other non-woven materials, such as those made from plastics, natural fibers, or synthetic fibers, differ in composition and properties. For instance, plastics-based non-wovens may be less durable and more prone to degradation, while natural fibers like cotton or wool offer different thermal and comfort properties. Each type of non-woven material has unique characteristics that make them suitable for specific applications, with fiberglass being particularly favored in construction, automotive, and aerospace industries due to its strength and durability.</p>

- Q: Is it possible to utilize black fiberglass tissue in medical settings for infection control purposes?

- <p>Black fiberglass tissue can be used in healthcare facilities for certain applications, such as insulation or structural reinforcement, due to its strength and durability. However, it is not typically used for direct patient contact or in areas where it might contribute to infection control. For infection prevention, healthcare facilities rely on materials that are easy to clean and disinfect, such as stainless steel, plastic, and certain types of fabric that are resistant to microbial growth. Black fiberglass tissue may not meet these criteria and could potentially harbor pathogens if not properly maintained, thus it is not recommended for use in areas critical for infection control.</p>

- Q: Is it possible to utilize black fiberglass tissue as an insulating material in construction?

- <p>Yes, black fiberglass tissue can be used for building insulation. It is a type of insulation material known for its thermal and acoustic insulation properties. Black fiberglass is made from glass fibers and is often used in construction for insulating walls, roofs, and floors. It helps to reduce heat transfer, thereby improving energy efficiency and comfort within the building. However, it's important to note that proper installation and safety precautions are necessary due to the potential health risks associated with fiberglass, such as skin and respiratory irritation.</p>

- Q: Can fiberglass facing be used in both residential and commercial buildings?

- Yes, fiberglass facing can be used in both residential and commercial buildings. It is a versatile material that offers insulation, soundproofing, and moisture resistance, making it suitable for various applications in both types of buildings.

1. Manufacturer Overview

| Location | Jangsu, China |

| Year Established | 1999 |

| Annual Output Value | Above US$0.3 billion |

| Main Markets | 0.00% Mid East 15.00% Northern Europe 15.00% North America 10.00% Eastern Asia 20.00% Africa 0.00% Eastern Europe 20.00% Southeast Asia 0.00% Oceania 0.00% Western Europe 0.00% Southern Europe 0South east asia;North America |

| Company Certifications | ISO 9001:2008 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 41% - 50% |

| No.of Employees in Trade Department | 20 People |

| Language Spoken: | English; Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 4 |

| Contract Manufacturing | OEM Service Offered; Design Service Offered |

| Product Price Range | Average |

Send your message to us

Fiberglass Facing Black Fiberglass Cloth BFC-001

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 10000M2 m²

- Supply Capability:

- 50000M2 Per Week m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords