Fiberglass Fabrics - e-glass fiberglass cloth

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Structure of Fiberglass Cloth Description:

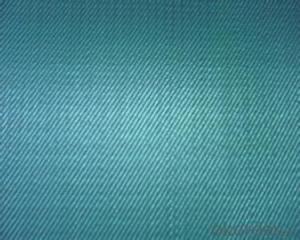

1.The fabric of fiberglass cloth is woven by fiber glass yarn, which is treated with silane coupling agent, the kind of weave is plain.

2.It is base material of high strength,low extensibility,coating with resin

easily and surface flat and so on.

Main Features of the Fiberglass Cloth:

It has good characteristics of high tensile strength, stable tension, and no defect appearance. The fiberglass fabric can be widely applied in different industrial application such as: PTFE, silicon, PVA, PVC, PU and acrylic coating, thermal, insulation and others application.

Fiberglass Cloth Images:

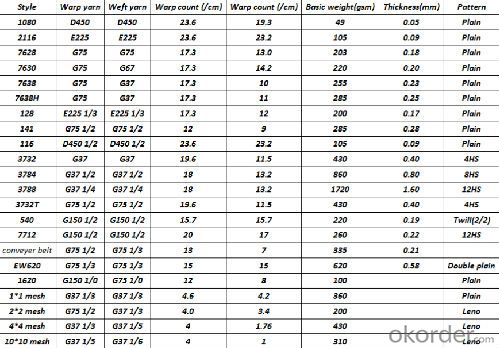

Fiberglass Cloth Specification:

FAQ of Fiberglass Cloth:

Delivery Detail: 15-21days

Other spec. can be custom made as per customer's request.

- Q: How is fiberglass fabric used in the production of sports helmets?

- Fiberglass fabric is used in the production of sports helmets as it provides strength and durability to the overall structure. The fabric is commonly used as a reinforcement material in the helmet's shell, allowing it to withstand impacts and distribute the force of the impact across the surface of the helmet. This helps to protect the wearer's head from potential injuries during sports activities.

- Q: Can fiberglass fabrics be used for insulation in industrial machinery?

- Fiberglass fabrics are indeed applicable for insulating industrial machinery. Their remarkable thermal insulation properties stem from their low thermal conductivity. They possess a strong resistance to heat transfer, rendering them an appropriate selection for insulating industrial machinery that functions under high temperatures. Moreover, fiberglass fabrics are non-flammable and exhibit commendable resistance to chemicals, ensuring a secure and enduring choice for insulation in industrial environments. They proficiently capture heat and prevent energy dissipation, thereby enhancing the overall efficiency and performance of the machinery. All in all, fiberglass fabrics prove to be a dependable and efficient alternative for insulating industrial machinery.

- Q: Can fiberglass fabric be used for insulation in steam systems?

- Fiberglass fabric is indeed suitable as insulation in steam systems. Its exceptional thermal insulation properties and ability to withstand high temperatures make it a favored option. By effectively capturing the steam's heat, it prevents any loss of heat and enhances energy efficiency in the system. Moreover, fiberglass fabric's lightweight, flexible, and effortless installation process make it a convenient choice for insulating steam pipes and equipment. Its non-combustible nature also ensures safety in steam systems. All in all, fiberglass fabric is a dependable and efficient insulation material for steam systems.

- Q: What is the width range of fiberglass fabric?

- The width range of fiberglass fabric typically varies from 1 inch to 120 inches, depending on the specific requirements and applications.

- Q: Are fiberglass fabrics resistant to water absorption?

- Yes, fiberglass fabrics are generally resistant to water absorption. Fiberglass is a non-porous material, which means it does not allow water to pass through easily. This makes it highly resistant to water absorption. When used in fabrics, fiberglass is often coated with a water-resistant finish or treated with chemicals to further enhance its resistance to water absorption. This makes fiberglass fabrics suitable for a variety of applications where water resistance is important, such as in outdoor clothing, marine equipment, and waterproofing materials. However, it is important to note that while fiberglass fabrics are resistant to water absorption, they may not be completely waterproof. In extreme conditions, such as prolonged exposure to heavy rain or submersion in water, some water may eventually seep through the fabric.

- Q: Can fiberglass fabric be used for reinforcement in boat hulls?

- Yes, fiberglass fabric can be used for reinforcement in boat hulls. It is a common and popular material for strengthening and reinforcing boat structures due to its high strength-to-weight ratio, durability, and resistance to water and corrosion.

- Q: Is fiberglass fabric suitable for making tents and awnings?

- Yes, fiberglass fabric is suitable for making tents and awnings. It is lightweight, durable, and offers excellent resistance to extreme weather conditions such as rain, wind, and UV rays. Additionally, fiberglass fabric is known for its strong tensile strength and fire resistance, making it a reliable choice for outdoor applications.

- Q: Is fiberglass fabric flame resistant?

- Yes, fiberglass fabric is flame resistant. It is made from glass fibers that have been woven into a fabric. The glass fibers have a high melting point, which makes the fabric highly resistant to catching fire or melting. This makes fiberglass fabric a popular choice in applications where flame resistance is important, such as in insulation, protective clothing, and fireproof curtains. However, it is important to note that while fiberglass fabric is flame resistant, it is not completely fireproof. It may still burn if exposed to high temperatures for prolonged periods of time.

- Q: Is fiberglass fabric resistant to chemicals in laboratories?

- Yes, fiberglass fabric is generally resistant to a wide range of chemicals commonly used in laboratories. Its inherent chemical resistance makes it a preferred material for protective clothing, lab aprons, and other applications where exposure to chemicals is expected.

- Q: What are the different weave styles available for fiberglass fabric?

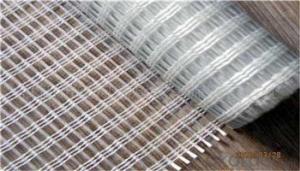

- There are several different weave styles available for fiberglass fabric, each with its own unique characteristics and applications. Some of the most common weave styles include plain weave, twill weave, satin weave, and leno weave. 1. Plain weave: This is the simplest and most common weave style for fiberglass fabric. It consists of a simple over-under pattern where each warp yarn passes alternately over and under each weft yarn. Plain weave fabrics are typically balanced and have good stability, making them suitable for a wide range of applications. 2. Twill weave: Twill weave is characterized by a diagonal line pattern on the fabric surface. This weave style is created by passing the weft yarn over two or more warp yarns before going under one or more warp yarns. Twill weave fabrics have good strength and durability, making them ideal for applications that require a higher level of performance. 3. Satin weave: Satin weave is known for its smooth and lustrous appearance. It is created by passing the weft yarn over four or more warp yarns before going under one. This weave style produces a high number of floats on the fabric surface, resulting in a silky texture. Satin weave fabrics are lightweight, flexible, and have excellent draping qualities, making them ideal for applications that require a smooth and elegant finish. 4. Leno weave: Leno weave is a unique weave style that creates an open mesh-like structure. It is formed by twisting adjacent warp yarns together and then locking them in place with a weft yarn. Leno weave fabrics are characterized by their high porosity and excellent breathability. They are commonly used in filtration applications and for reinforcing composites. These are just a few examples of the different weave styles available for fiberglass fabric. The choice of weave style depends on the specific requirements of the application, such as strength, weight, flexibility, and aesthetics.

Send your message to us

Fiberglass Fabrics - e-glass fiberglass cloth

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords