Self Adhesive Fiberglass Mesh Fabric with High Silica Texturized Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Description:

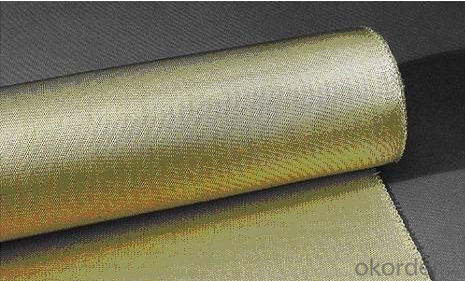

Our Silica Fibre fire Sleeve is an extreme high temperature, heat and flame resistant silica tape, and is an excellent alternative to asbestos and ceramic based textiles. The Silica Fibre Sleeve are primarily used as the thermal protection of circular items, the sleeves can be applied in aerospace (gas turbin and rocket engines), metallurgical, nuclear power, electricity generation, petrochemical industries, etc. for example, tube seals, high temperature gaskets, heaters,reformers,turbine exhaust,boilers, thermocouple wire,etc.

Applifications:

High silica texturized tapes can be used for a long period of time without changing its properties at the temperature of 1000℃,as it contains more than 96% silica.The performance of thermal insulation is excellent because of its texturized structure..

Application:Industrial wires,cables and pipes as thermal insulation material,heat gasket and seal material.

Specification:

| Product Code | SiO2 % | Working Temperature ℃ | Width mm | Thickness | Packing M/Roll |

| TSIP-32-0.8 | ≥94% | 1000 | 32-100 | 0.8 | 10,15,20 |

| TSIP-32-1.0 | ≥94% | 1000 | 32-100 | 1 | 10,15,20 |

| TSIP-32-1.5 | ≥94% | 1000 | 32-100 | 1.5 | 10,15 |

| TSIP-32-2.0 | ≥94% | 1000 | 32-100 | 2 | 10,15 |

| TSIP-32-2.5 | ≥94% | 1000 | 32-100 | 2.5 | 10,15 |

Package and delivery time

Package:Each roll in a polybag,then several rolls in one standard export carton box.

Delivery time:Within 7-15days

FAQ:

1.What is the delivery time ?

15days after receiving the deposit

2.Are you a trading company or factory.

We are factory,and we have more than 10 years of experience.

- Q: Polyurethane waterproof coating how to use, polyurethane waterproof coating what are the methods of use?

- Polyurethane waterproof coating construction process: 1., cleaning the base, 2. brushing glue, 3. details additional layer, 4., the first coating, 5., second coating, 6., third coating and clay slag.

- Q: Is fiberglass fabric resistant to flame spread?

- Indeed, flame spread is resisted by fiberglass fabric. This material is non-flammable and does not readily ignite. With a high ignition temperature and the inability to support combustion, fiberglass fabric finds extensive use in various applications that prioritize fire resistance. These include insulation materials, protective clothing, and fireproof curtains. Furthermore, fiberglass fabric exhibits exceptional durability even under extreme temperatures, rendering it an ideal option for environments where fire safety is paramount.

- Q: Can fiberglass fabric be used for making sports equipment?

- Sports equipment can indeed be made using fiberglass fabric. This fabric, being versatile, offers a wide range of advantages such as its lightweight nature, strength, and durability. These qualities make it an ideal material for high-performance sports equipment like surfboards, skis, and hockey sticks. By using fiberglass fabric to reinforce the structure of these items, they become stronger and more rigid while still maintaining their lightweight design. Moreover, fiberglass fabric can easily be molded into different shapes, allowing for customization and improving the performance of sports equipment. All in all, fiberglass fabric is a popular and well-liked choice in the sports industry due to its versatility, strength, and ability to enhance the performance of sports equipment.

- Q: Are fiberglass fabrics resistant to moisture or humidity?

- Yes, fiberglass fabrics are highly resistant to moisture and humidity.

- Q: Can fiberglass fabrics be used for insulation in industrial boilers?

- Indeed, insulation in industrial boilers can be accomplished by employing fiberglass fabrics. Fiberglass, renowned for its exceptional thermal resistance characteristics, is widely favored for insulation purposes across numerous domains. This lightweight and pliable material adeptly captures heat and thwarts its dispersion to the adjoining surroundings. In industrial boilers, fiberglass fabrics can be employed as insulating covers or jackets, thereby preserving heat within the system and heightening energy efficiency while minimizing heat dissipation. Furthermore, fiberglass boasts a non-combustible nature, rendering it a secure choice for insulation in high-temperature settings like industrial boilers.

- Q: Does the construction of insulation alkali resistant glass fiber cloth need fixing with thermal insulation nail?

- The alkali resistant mesh cloth does not need to be fixed (direct pressed into the anti cracking mortar surface), and galvanized steel wire mesh needs to be fixed with an anchor bolt.

- Q: How to distinguish carbon fishing rod?

- Glass steel pole rough texture, mesh patterns, can be seen across the warp, weft. Carbon rod fine texture, no pattern wall, a black color, even some reticular pattern, and carbon fiber cloth, the fine, silvery white, glass and steel rods significantly different warp and weft weaving. Carbon pole strength, good conductivity, wear resistance, high temperature resistance, corrosion resistance characteristics.

- Q: Can fiberglass fabric be used for insulation in storage tanks?

- Yes, fiberglass fabric can be used for insulation in storage tanks. Fiberglass fabric is known for its excellent thermal properties, making it an ideal choice for insulation applications. It has a low thermal conductivity, meaning it can effectively reduce heat transfer, keeping the contents of the storage tank at the desired temperature. Additionally, fiberglass fabric is lightweight, flexible, and easy to install, making it a convenient option for insulating storage tanks of various shapes and sizes. It is also resistant to moisture, chemicals, and UV radiation, ensuring its durability and longevity. Overall, fiberglass fabric is a reliable and efficient choice for insulating storage tanks.

- Q: Can fiberglass fabric be used for medical devices?

- Certain medical devices can utilize fiberglass fabric due to its various properties. Lightweight and flexible with a high strength-to-weight ratio, this fabric is well-suited for durable and supportive devices. Moreover, it is non-toxic and non-allergenic, making it essential for medical devices in contact with the human body. Orthopedic braces, prosthetics, casts, and splints are among the medical applications where fiberglass fabric finds use. Nonetheless, it is crucial to sterilize and test the fabric for biocompatibility prior to employing it in medical devices to guarantee compliance with safety standards.

- Q: Is fiberglass fabric suitable for use in food packaging?

- No, fiberglass fabric is not suitable for use in food packaging. Fiberglass is made from tiny glass fibers that can easily break off and contaminate the food. These fibers may pose a health risk if ingested. Additionally, fiberglass fabric is not designed to be food-safe and may not meet the necessary standards for food packaging materials. It is important to choose packaging materials that are specifically designed and approved for food contact to ensure the safety and quality of the packaged food.

Send your message to us

Self Adhesive Fiberglass Mesh Fabric with High Silica Texturized Tape

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords