PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

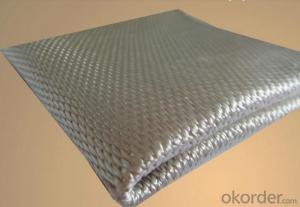

Fiberglass Fabric with Silicone Coated for Electric Insulation

Fiberglass Fabric Description

Silicone coated fiberglass fabric is a fiberglass cloth, which possesses the properties of temperature resistance, anti-corrosion, high strength and is coated with organic silicone rubber.

Fiberglass Fabric Specification

Thickness:0.2mm-5mm

Width:100cm-150cm

Color;grey/red/silver/black

Weight(coating):130gsm-2800gsm

Model No | FSD2030 | FSD2030 | FSD2050 | FSD2100 | |

High temperature resistant(°C) | ≤280 | ≤280 | ≤280 | ≤280 | |

Low temperature resistant(°C) | ≥-40 | ≥-40 | ≥-40 | ≥-40 | |

Tensile intensity (N/50mm) | Warp | ≥1750 | ≥1750 | ≥2500 | ≥3500 |

Weft | ≥1280 | ≥1280 | ≥2100 | ≥3000 | |

Inflating burst intensity(Mpa) | ≥2.0 | ≥2.0 | ≥2.2 | ≥2.6 | |

Peeling intensity(N/m) | ≥450 | ≥450 | ≥520 | ≥600 | |

Insulation (kv/mm) | 16 | 16 | 18 | 18 | |

Weight (g/m*m) | 550-650 | 550-650 | 750-800 | 1500-1800 | |

Width(mm) | 1000±20 | 1000±20 | 1000±20 | 1000±20 | |

Thickness(mm) | 0.3-0.4 | 0.3-0.4 | 0.05-0.55 | 1.0-1.1 | |

color | Silver-gray, gray, red | lucency | Silver-gray, gray, red | Black, gray, red | |

Fiberglass Fabric Features:

1, Good performance on resisting high temperature and low temperature, -40°C-280°C;

2, High strength;

3, Ozone, oxide, light and weather aging resistance;

4, High insulation: dielectric constant:3-3.2, breakdown voltage: 20-50KV/MM;

5, Chemical corrosion resistant, oil-proofing, waterproofing (washable)

Fiberglass Fabric Application:

It has been widely used in construction, electric insulation,

chemical industry, pipeline ductile conjunction, large generating

Corrosion proofing field, machinery, metallurgy, sealing and so on.

Product Show

FAQ

1.What are the characteristics of fiberglass fabric?

a)Outstanding temperature resistance(from -70°C to +260°C)

b)Excellent chemical resistance

c)Superior non-stick surface, easy to clean

d)High dielectric strength

e)Dimensional stability

f)Resistance to UV, IR and HF

g)Non-toxic

2.How many methods to weave the fabric?

Four methods to weave the fabric:

a).Plain weave: it can be used in electricity insulation materials and reinforced materials in industry, because of inseparable structure, plain and clear lines.

b).Twill weave: compared with plain weave, it is of high density, high intensity, with a soft and loose structural weave. It can be used in ordinary reinforced materials, filter materials, and painting cloth.

c) Satin weave: compared with plain weave and twill weave, it is of high density,high intensity, with a soft and loose structural weave with a good texture. It is applicable for use as a higher reinforced material in machinery.

d).Gauze weave: said lattice twist weave. It can be used in spread model curtain,resin reinforced emery wheel gray cloth and lattice embed belt.

3.Can you offer us some samples?

We are willing to offer our customers best product&service,if it's necessary we can send

you sample for test;also we welcome all you customer have a trial order.

- Q: Can fiberglass fabric be used for making gloves?

- Gloves can indeed be made using fiberglass fabric. This material is known for its strength and durability, offering exceptional resistance against heat and fire. Its usage is prevalent in industries that demand protection against high temperatures or when working with hot objects. By weaving or knitting fiberglass fabric, gloves can be created to form a shield against heat, sparks, and flames, safeguarding the hands. Nevertheless, it is crucial to bear in mind that fiberglass may cause skin irritation and itchiness. Therefore, it is imperative to observe appropriate precautions and safety measures while utilizing gloves made from fiberglass fabric.

- Q: Can fiberglass fabrics be used for reinforcement in electronic devices?

- Yes, fiberglass fabrics can be used for reinforcement in electronic devices. They are commonly used as a reinforcement material in electronic circuit boards, providing mechanical strength and insulation properties. Additionally, fiberglass fabrics offer good resistance to heat, chemicals, and electrical conductivity, making them suitable for reinforcing electronic components.

- Q: Anticorrosion floor construction

- Anticorrosive floor paint is three components of paint, suitable for corrosion protection tanks, heavy machinery surface treatment and chemical enterprises, corrosion prone areas of the floor, anti-corrosion engineering of the oil industry and sewage pond, chemical pool, etc.. Strong permeability, strong acid, alkali, salt and various organic solvents, high surface hardness, good compactness.

- Q: Can fiberglass fabric be used for making curtains or dividers?

- Yes, fiberglass fabric can be used for making curtains or dividers. It is a versatile material that offers durability, strength, and fire resistance, making it suitable for various applications, including curtains and dividers. Additionally, fiberglass fabric can also provide insulation and noise reduction properties, making it a practical choice for these purposes.

- Q: The pipe is too hot. What's the protection?

- Hot water pipes can be added to the outer wall insulation cotton protection.

- Q: What's the price of fiberglass fabric penetrant?

- The company has strong technical ability, can help customers solve various formulations problems.

- Q: What are the different fiberglass fabric finishes for water resistance?

- There are several different fiberglass fabric finishes that can enhance water resistance, such as silicone, polyurethane, acrylic, PTFE (Teflon), and vinyl coatings. These finishes create a protective barrier on the fabric surface, preventing water penetration and increasing durability in wet conditions.

- Q: What is the difference between epoxy fiber glass cloth flooring and anticorrosive floor?

- Now the basic concrete curing terrace, do not believe you can do Baidu search, certainly want to do a little, you say is not.

- Q: What are the different printing options available for fiberglass fabric?

- There are several printing options available for fiberglass fabric, each with its own unique advantages and applications. 1. Screen Printing: This is a popular printing method for fiberglass fabric due to its versatility and ability to produce vibrant and detailed designs. Screen printing involves pushing ink through a mesh screen onto the fabric, creating a durable and long-lasting print. It is suitable for both small and large print runs and can be used for a wide range of designs and patterns. 2. Digital Printing: This method utilizes inkjet printers to directly print the desired design onto the fiberglass fabric. Digital printing offers high-resolution prints with intricate details and is particularly well-suited for complex and multicolored designs. It also allows for more flexibility in customization and is ideal for smaller quantities. 3. Sublimation Printing: Sublimation printing involves transferring ink onto the fiberglass fabric through a heat press. The ink is first printed onto a transfer paper and then heat-pressed onto the fabric, resulting in vibrant and permanent prints. Sublimation printing offers excellent color reproduction and is often used for customized or personalized designs. 4. Heat Transfer Printing: Similar to sublimation printing, heat transfer printing involves transferring the ink onto the fabric using heat. However, unlike sublimation printing, heat transfer printing utilizes pre-printed designs on transfer paper or vinyl, which are then heat-pressed onto the fabric. This method is commonly used for designs that require specific colors or effects that are not achievable through other printing methods. 5. Rotary Printing: Rotary printing is a continuous printing process where the fabric is passed between a rotating cylinder and a stationary screen. This method is suitable for high-volume production as it allows for fast printing speeds and consistent quality. Rotary printing is often used for large-scale projects and can produce intricate patterns and designs. Overall, the choice of printing option for fiberglass fabric depends on factors such as the design complexity, quantity, budget, and desired end result. Each printing method has its own advantages and limitations, so it is important to consider these factors when selecting the most suitable option for a specific project.

- Q: Latex paint cracking, how to deal with latex paint cracking what are the reasons?

- Many aspects of the analysis of the need to check, if it is to see whether the cracking, hollowing, accompanied by size, such as the large area, it should be cut off, and with several layers of cement mortar with good, after drying in the paste glass fiber cloth or high elastic fiber tape, the area is greater than the chiseling area, and then blow good putty, paint paint can.

Send your message to us

PVC Coated Fiberglass Fabric for Electric Insulation

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 500 m²

- Supply Capability:

- 50000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords