Fiberglass Mat Tissue - Glass Wool Insulation Blanket CNBM Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Description of Glass Wool Insulation Blanket:

Glass Wool Blanket Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping. Also complete glass wool production lines employing latestgeneration technology to manufacture boards, rolled blankets and pipes for residential and industrial thermal and acoustic insulation needs, in compliance with the top international standards (EN, DIN, ASTM).

At the system HOT END, the raw materials are dosed, mixed, melted, fiberized, impregnated with a special binder and formed into a primitive mat of very fine fiber glass. Continuous conveyors transport the mat to the COLD END of the plant for binder polymerization. The product is then cut to shape and packed for shipping.

2.Main features of Glass Wool Blanket:

1.Light weight and easy to fabricate on job site

2.Excellent thermal, acoustical properties

3.Non-combustible and fire-retardant

4.Very economical, especially when using thick layers of insulation

5.Durable, life-time and termite proof

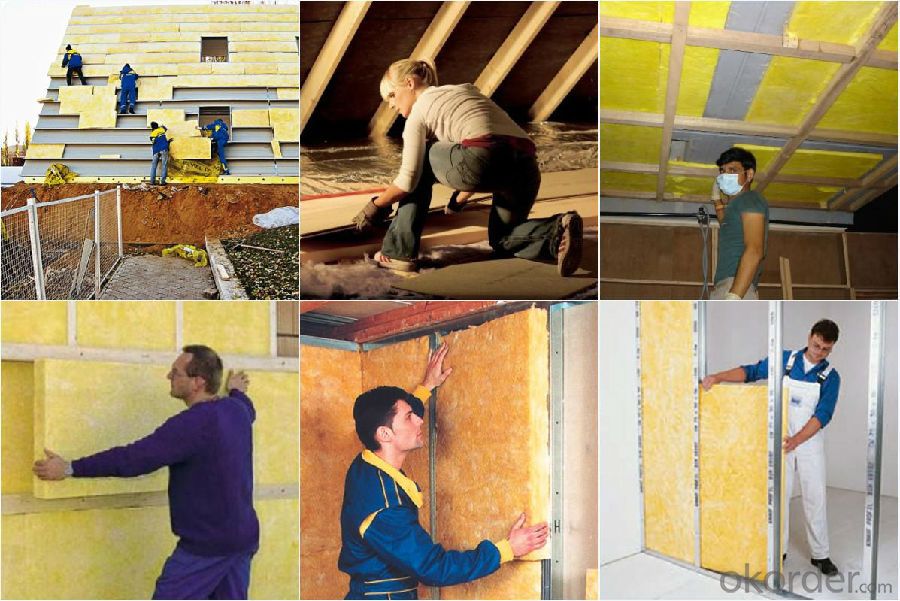

3.Glass Wool Blanket Images:

4. Glass Wool Insulation Blanket Technical Parameters:

Property | High/low temperature resistance, oil and fuel resistance, weathering resistance, O zone resistance etc. |

Shape | According to your requirement. |

Color | Any color is available ,according to your requirements. |

Material | NBR, CR, SBR, EPDM, IIR, NR, EP, Silicone, VITON etc. |

Hardness | 30-90ShoreA |

Delivery | In 10 days |

Packing | Plastic bag & carton box or according to your requirements. |

Application | Electronic field, industrial machine & equipment, house-hold appliance, telecommunication, automobile, medical equipment industry etc. |

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of Glass Wool Blanket is one of the large scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirement.

②How to guarantee the quality of the products?

We have established the international advanced quality management system every link from raw material to final product we have strict quality test; We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: What is the tear resistance of fiberglass mat tissue?

- The ability of fiberglass mat tissue to withstand tearing or ripping when exposed to mechanical stress or force is referred to as its tear resistance. Due to its strong and durable nature, fiberglass mat tissue is renowned for its high tear resistance. This tear resistance is typically quantified and reported as tear strength, which measures the force needed to tear the material. The determination of tear strength involves standardized testing methods like the Elmendorf tear test or the tongue tear test. Various factors, including thickness, density, and composition, can influence the tear resistance of fiberglass mat tissue. Nevertheless, fiberglass mat tissue generally exhibits outstanding tear resistance properties, making it an excellent choice for applications where durability and strength are crucial, such as in the construction industry for reinforcement materials or in the production of composite materials.

- Q: What are the different reinforcement orientations available for fiberglass mat tissue?

- The different reinforcement orientations available for fiberglass mat tissue include random chopped strand mat (CSM), continuous strand mat (CSM), woven roving, and unidirectional fiberglass.

- Q: Does fiberglass mat tissue require any maintenance?

- Fiberglass mat tissue does not typically require any maintenance once it has been installed. This material is designed to be durable and long-lasting, capable of withstanding various environmental conditions. Unlike other materials, fiberglass mat tissue is resistant to rot, corrosion, and decay, making it a low-maintenance option for many applications. However, it is important to note that proper installation is crucial to ensure the longevity and effectiveness of fiberglass mat tissue. It should be installed according to manufacturer guidelines, ensuring that it is properly bonded and sealed to the surface. This will help prevent any potential issues or damage that may arise from improper installation. In some cases, fiberglass mat tissue may require occasional cleaning to remove any dirt or debris that may accumulate over time. This can be done using mild soap and water, or by following the manufacturer's recommended cleaning instructions. Overall, while fiberglass mat tissue does not require regular maintenance, it is important to address any issues or damages promptly to prevent further deterioration. Regular inspections and necessary repairs should be carried out to ensure the continued performance and longevity of the material.

- Q: Can fiberglass mat tissue be used for insulation in underground pipelines?

- Indeed, insulation in underground pipelines can be achieved using fiberglass mat tissue. Renowned for its outstanding thermal insulation characteristics, fiberglass mat tissue is widely employed across diverse industrial sectors, including underground pipeline installations. By impeding heat transfer between the pipeline and its surroundings, it effectively sustains the desired temperature within the pipeline, thereby providing insulation. Furthermore, fiberglass mat tissue exhibits resistance against moisture, chemicals, and corrosion, rendering it an optimal selection for underground scenarios where pipelines face harsh conditions. Consequently, fiberglass mat tissue emerges as a dependable and efficacious insulation material for underground pipelines.

- Q: How does fiberglass mat tissue compare to other types of insulation materials?

- Fiberglass mat tissue is a type of insulation material that has its own unique characteristics and advantages when compared to other insulation materials. Firstly, fiberglass mat tissue is known for its excellent thermal insulation properties. It has a low thermal conductivity, meaning it effectively reduces the transfer of heat between the inside and outside of a building. This helps to keep buildings cooler in the summer and warmer in the winter, leading to energy savings and increased comfort. In addition to its thermal insulation capabilities, fiberglass mat tissue also offers excellent sound insulation. It helps to reduce noise transmission through walls and floors, creating a quieter and more peaceful indoor environment. This is particularly beneficial in commercial buildings, where noise reduction is important for productivity and customer satisfaction. Furthermore, fiberglass mat tissue is a lightweight and flexible material, making it easy to handle and install. It can be easily cut to fit around obstacles such as pipes and ducts, ensuring a tight and efficient insulation barrier. This ease of installation saves time and labor costs during construction or renovation projects. Another advantage of fiberglass mat tissue is its fire resistance. It is a non-combustible material, meaning it does not contribute to the spread of fire. This is especially crucial in buildings where fire safety is a top priority, such as hospitals, schools, and residential properties. Moreover, fiberglass mat tissue is durable and long-lasting. It does not degrade or lose its insulation properties over time, ensuring consistent energy efficiency and performance for many years. This durability makes it a cost-effective insulation choice, as it reduces the need for frequent replacement or maintenance. Lastly, fiberglass mat tissue is environmentally friendly. It is made from recycled glass and sand, which reduces the demand for raw materials. Additionally, it is recyclable at the end of its lifespan, further reducing waste and promoting sustainability. Overall, fiberglass mat tissue offers excellent thermal and sound insulation, ease of installation, fire resistance, durability, and environmental benefits. While other insulation materials may have their own advantages, fiberglass mat tissue is a versatile and reliable option for various applications.

- Q: Does fiberglass mat tissue provide any moisture insulation?

- No, fiberglass mat tissue does not provide any moisture insulation.

- Q: What is the specific gravity of fiberglass mat tissue?

- The specific gravity of fiberglass mat tissue typically ranges between 1.5 and 2.0.

- Q: Is fiberglass mat tissue suitable for marine applications?

- Yes, fiberglass mat tissue is suitable for marine applications. It is a commonly used material in the marine industry due to its durability, strength, and resistance to water and corrosion. Fiberglass mat tissue is lightweight, making it ideal for boat construction and repairs. It is also highly resistant to UV rays, chemicals, and harsh weather conditions, which are common in marine environments. Moreover, it provides excellent structural reinforcement and can be easily shaped and molded to fit various marine components. Overall, fiberglass mat tissue is a reliable and versatile material for marine applications.

- Q: What is the expected lifespan of fiberglass mat tissue in cleanroom applications?

- Several factors can influence the expected lifespan of fiberglass mat tissue in cleanroom applications. The durability and long-lasting properties of fiberglass mat tissue are well-known in cleanrooms. However, variables such as contamination level, cleaning procedures, maintenance practices, and overall cleanroom conditions can impact its lifespan. By providing proper care and regular maintenance, fiberglass mat tissue can typically endure for several years in cleanroom applications. Extending its lifespan can be achieved through frequent cleaning and replacing any damaged or contaminated sections. Following the manufacturer's guidelines and recommendations for cleaning and maintenance is crucial to ensure optimal performance and longevity. Furthermore, the expected lifespan of fiberglass mat tissue can also be influenced by its quality and grade. Higher-quality materials exhibit greater resilience and can withstand environmental stressors better than lower-grade options. Therefore, investing in high-quality fiberglass mat tissue can contribute to a longer lifespan in cleanroom applications. To summarize, there is no definitive answer regarding the exact expected lifespan of fiberglass mat tissue in cleanroom applications. However, regular maintenance, proper care, and the use of high-quality materials can significantly increase its longevity.

- Q: What are the potential health and safety concerns associated with working with fiberglass mat tissue?

- Working with fiberglass mat tissue can pose potential health and safety concerns. The fine fiberglass particles present in the air during handling and cutting can be inhaled, leading to respiratory issues such as irritation, coughing, and difficulty breathing. Prolonged exposure to these particles may also result in long-term lung damage. Additionally, direct skin contact with the fiberglass can cause skin irritation and allergic reactions. Hence, it is important to use appropriate personal protective equipment, such as gloves, masks, and goggles, to minimize these risks and ensure a safe working environment.

Send your message to us

Fiberglass Mat Tissue - Glass Wool Insulation Blanket CNBM Best Quality

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5000 m²

- Supply Capability:

- 20000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords