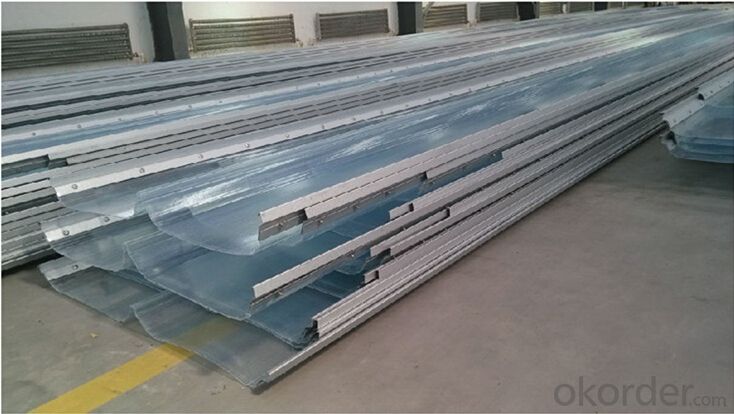

FRP Pultrusion Profiles - Fiber Reinforce Plastic Skylight Panel with Aluminum Edge

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications

FRP Skylight Panel with Aluminum Edge

1. UV Resistance: 100%;

2. Light Transmittance: 3%-85%;

3. Fiber Content: 25% - 35%

Product Description

Specifications of FRP Skylight Panel with Aluminum Edge :

1. High Quality FRP plate

2. UV Protection

3. High strength, good light transmission

Technical date of FRP Plate

Density | 1.45 g/cm3 | Tensile strength | 75Mpa |

Fiber content | 25% - 35% | Bending strength | 125Mpa |

Curing degree | >82% | Impact ductility | 90 KJ/M2 |

Weathering film thickness | 20-30μm | Thermal conductivity | 0.158 W/m.k |

Light transmissivity | 3% - 85% | Thermal expansivity | 2.6x10-5mm/mm/°C |

Suitable temperature | -40~ +120 | UV Resistance | 100% |

Thickness of PRP plate:1.2mm ~1.8mm, tolerance ± 10%;

Thickness of coated steel tile: 0.5mm, the color should be consistent with the roof colorplate;

Thickness of aluminum zine plate: 0.5mm

Weidth:<1.1m, different width according to the profile

Length: Accordingto the demand

Color: Clear blue, Light blue, Lake blue, Sky blue, Deepblue, Clear white, Solid white, Gray white, Black, Clear green or Customizable

Product Types: Single layerskylight, insulation double layers skylight in normal

Features: Anti condensation, heatinsulation, noise insulation, good water tightness, ensure the roof structure,energy saving and environmental protection, 360 degree upright occlusion, goodappearance.

Match the coated steel tile, easy installation. According to differentcustomer needs to produce products that satisfy you!

Occlusion Types:

1. Single 360 degree of occlusion;

2. Double 360 degree of occlusion;

3. Single 180 degree of occlusion;

4. Double 180 degree of occlusion.

Advantages:

1. Vertical occlusion, avoid leakageand seepage;

2. Convenient installation;

3. Ensure the whole roof structure

4. Low cost maintenance;

5. Prevent condensation

6. Good sound insulation, heatinsulation, thermal preserve

Application : High demandelectronics factory, valuables storage workshop, high precision machine shop,cold regions need to heat insulation lighting workshop, etc.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical manufacturing?

- FRP pultrusion profiles are well-known for their resistance to chemicals utilized in the pharmaceutical manufacturing industry. These profiles are created by saturating fibers with a resin matrix, typically polyester or vinyl ester. This resin matrix offers exceptional chemical resistance, allowing the profiles to endure exposure to a wide variety of chemicals, including acids, alkalis, solvents, and cleaning agents frequently employed in pharmaceutical manufacturing procedures. Due to the combination of fiber reinforcement and a chemical-resistant resin matrix, FRP pultrusion profiles are an excellent option for applications that involve contact with aggressive chemicals. Unlike traditional materials such as steel or wood, FRP profiles do not corrode or undergo chemical reactions when in contact with substances. Moreover, FRP pultrusion profiles provide numerous additional benefits for pharmaceutical manufacturing applications. They possess a remarkable strength-to-weight ratio, are non-conductive, and exhibit high mechanical resistance. Furthermore, FRP is a non-porous material, preventing the absorption or release of chemicals. This characteristic is crucial for maintaining strict hygiene standards and preventing contamination in pharmaceutical processes. In conclusion, FRP pultrusion profiles are a dependable and long-lasting choice for pharmaceutical manufacturing environments, offering excellent resistance to the chemicals typically encountered in these processes.

- Q: Can FRP pultrusion profiles be used in water treatment plants?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in water treatment plants. FRP pultrusion profiles offer several advantages that make them well-suited for use in this industry. Firstly, FRP pultrusion profiles are highly corrosion resistant. Water treatment plants often have aggressive environments with exposure to chemicals and moisture, which can cause corrosion and degradation of traditional materials like steel. However, FRP pultrusion profiles are immune to corrosion, making them an ideal choice for water treatment applications. Secondly, FRP pultrusion profiles have excellent strength-to-weight ratios. This means that they provide high structural integrity while being lightweight, making them easier to handle and install in water treatment plants. Additionally, their high strength allows them to withstand the loads and pressures typically encountered in these environments. Furthermore, FRP pultrusion profiles are electrically non-conductive. This is particularly advantageous in water treatment plants, where there may be a need to isolate electrical equipment or components to prevent short circuits and protect personnel. FRP profiles provide a safe and reliable solution in such cases. Lastly, FRP pultrusion profiles have a long service life with minimal maintenance requirements. They do not rot, rust, or corrode, ensuring durability and longevity even in harsh water treatment conditions. This reduces downtime and maintenance costs, making FRP profiles a cost-effective choice for water treatment plant applications. Overall, FRP pultrusion profiles are an excellent choice for use in water treatment plants due to their corrosion resistance, high strength-to-weight ratio, electrical non-conductivity, and long service life. Their use can contribute to improved efficiency, reduced maintenance, and increased durability in water treatment processes.

- Q: Can FRP pultrusion profiles be used in the transportation and logistics industry?

- Yes, FRP pultrusion profiles can be used in the transportation and logistics industry. These profiles offer a lightweight and high-strength alternative to traditional materials like steel or aluminum. They are resistant to corrosion, have excellent dimensional stability, and can be customized to meet specific design requirements. FRP pultrusion profiles are commonly used in applications such as truck bodies, trailers, shipping containers, and infrastructure for transportation and logistics purposes.

- Q: Do you have any high temperature resistant resin made of pultruded glass fiber reinforced plastic?

- Unsaturated polyester resin can not meet the high temperature requirements, epoxy resin also needs to be synthesized

- Q: Are FRP pultrusion profiles suitable for the manufacturing of boat hulls?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are suitable for the manufacturing of boat hulls. Their high strength-to-weight ratio, corrosion resistance, and durability make them an ideal choice for boat construction. Additionally, pultruded profiles can be customized to meet specific design requirements and offer excellent dimensional stability, making them a reliable option for boat hull manufacturing.

- Q: Do FRP pultrusion profiles require any special tools for installation?

- Installation of FRP pultrusion profiles necessitates the use of specialized tools. These profiles are manufactured through a continuous process wherein fibers are drawn through a resin bath and subsequently into a heated die, resulting in a material that is not only strong and lightweight but also resistant to corrosion. To ensure the proper installation of FRP pultrusion profiles, various specific tools are commonly employed. These tools encompass: 1. Cutting Tools: During installation, it may be necessary to cut FRP profiles to specific lengths. To achieve clean and precise cuts, specialized cutting tools like high-speed saws or abrasive wheels are frequently utilized. 2. Drilling Tools: For the insertion of fasteners or other fittings, it might be necessary to drill holes in FRP profiles. To prevent damage to the profile while creating these holes, special drill bits designed for working with composite materials are typically employed. 3. Fastening Tools: Depending on the application, it may be necessary to fasten FRP profiles to other surfaces or structures. Commonly used fasteners include stainless steel screws, bolts, or adhesives, which are specifically chosen for their ability to securely hold the profiles in place. 4. Joining Tools: In certain instances, it may be necessary to join FRP profiles together in order to create longer lengths or more intricate shapes. To ensure a robust and secure connection, special joining techniques such as bonding, riveting, or the use of mechanical connectors are employed. It should be noted that the specific tools required for installation may vary depending on factors such as the complexity and size of the project, as well as the recommendations provided by the manufacturer. Therefore, it is always advisable to consult the manufacturer's installation guidelines or seek professional assistance to ensure the proper installation and optimal performance of FRP pultrusion profiles.

- Q: Are FRP pultrusion profiles resistant to rotting or decaying?

- Yes, FRP pultrusion profiles are highly resistant to rotting or decaying. FRP, or fiber-reinforced polymer, is a composite material that consists of a polymer matrix reinforced with fibers. This combination makes FRP pultrusion profiles highly durable and resistant to environmental factors such as moisture, chemicals, and UV radiation, which can lead to rotting or decaying in other materials. Therefore, FRP pultrusion profiles are an excellent choice for applications where long-term resistance to rotting or decaying is required.

- Q: Are FRP pultrusion profiles resistant to saltwater corrosion?

- Yes, FRP pultrusion profiles are highly resistant to saltwater corrosion. The combination of their fiberglass reinforcement and the corrosion-resistant resin matrix used in their manufacturing make them ideal for applications in marine environments. They are capable of withstanding prolonged exposure to saltwater without degradation or loss of structural integrity.

- Q: Are pultruded FRP sections strong? What are its main areas of application?

- More fields. Advantage is obvious, if the corrosion resistance, insulation resistance, quality is lighter than steel; strength and steel strength comparable;

- Q: Are FRP pultrusion profiles resistant to moisture absorption?

- FRP pultrusion profiles possess remarkable resistance to moisture absorption, primarily due to the composition of the materials used in their construction. These profiles typically consist of a combination of fiberglass and resin, wherein fiberglass is naturally non-porous and impervious to moisture, while the resin is specifically designed to repel moisture. The moisture resistance of FRP profiles is further enhanced by the pultrusion manufacturing process. This process involves pulling the fiberglass and resin through a heated die, ensuring thorough impregnation of the fibers with resin and creating a dense and solid structure. Consequently, the resulting product exhibits exceptional resistance to water penetration and moisture absorption. Additionally, the moisture resistance of FRP pultrusion profiles can be augmented through the application of protective coatings or surface treatments, such as gel coats or UV-resistant finishes. These coatings provide an extra layer of defense against moisture ingress. The superior moisture resistance of FRP pultrusion profiles makes them an ideal choice for applications that involve exposure to water or high humidity, such as marine environments, wastewater treatment plants, or outdoor structures. By preventing issues like rot, rust, or degradation commonly associated with materials like wood or metal, these profiles offer a reliable and durable solution that can endure moisture exposure without compromising their structural integrity or performance.

Send your message to us

FRP Pultrusion Profiles - Fiber Reinforce Plastic Skylight Panel with Aluminum Edge

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords