FRP Molded Grating For All Kinds Of Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

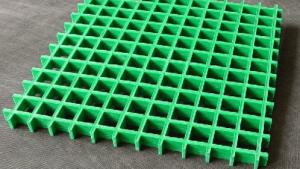

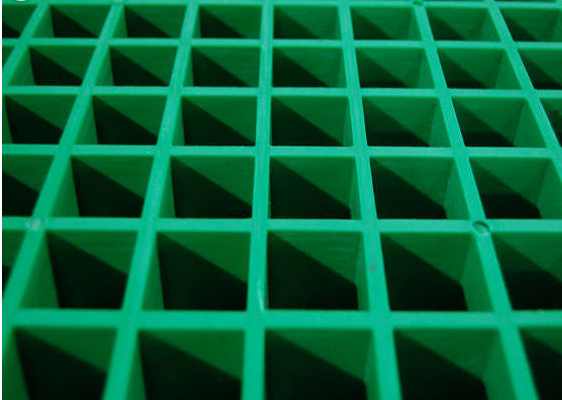

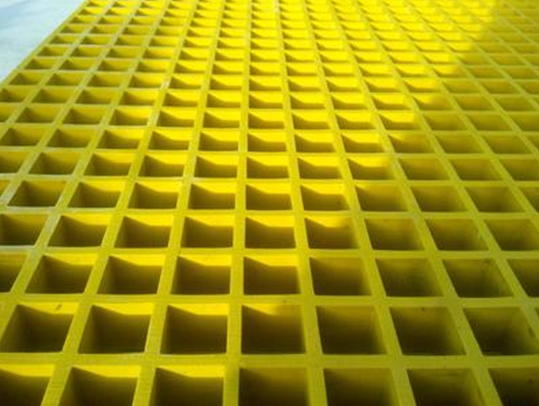

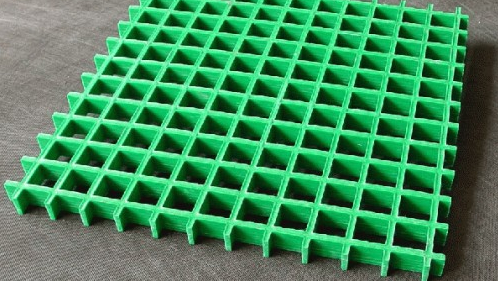

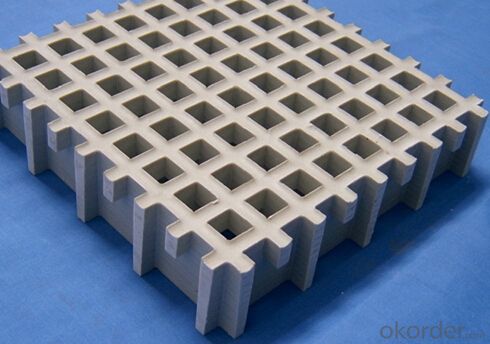

Product description of FRP Grating

FRP Grating, Molded FRP Grating, Fiberglass Grating, GRP Grating,GRP Molded Grating,FRP Pultrusion Grating, FRP Mini Mesh Grating,Trench Grating, Drain Grating,Grating Walkway, Platform Grating...

Comparing with other floor materials, FRP molded grating provides a series of benefits, unmatched impact resistance,

while the strength-weight-ratio is only one-fourth of that of steel grating. It is easy to cut and install.

Specification of FRP Grating

Item | Thickness mm | Mesh Size mm*mm | Panel Size mm*mm | Weight kg/Square Meter |

01 | 15 | 38*38 | 1223*3660 | 7 |

02 | 15 | 50*50 | 1223*3660 | 6.5 |

03 | 25 | 25*100 | 1010*3010 | 12.4 |

04 | 25 | 19*19 | 1223*3660 | 12.5 |

05 | 30 | 19*19 | 1223*3660 | 21.5 |

06 | 30 | 38*38 | 1223*4040 | 15.1 |

07 | 38 | 19*19 | 1223*3660 | 22.8 |

08 | 38 | 38*38 | 1000*4040 | 19.5 |

09 | 38 | 38*38 | 1223*3660 | 19.5 |

10 | 40 | 40*40 | 1250*3690 | 19.3 |

11 | 50 | 50*50 | 1223*3660 | 21.5 |

Images

Features

1.Corrosion and Chemical resistant

2.Slip-resistant

3.High strength-to-weight ratio

4.Ergonomic

5.Low maintenance

6.Fire retardant

7.Easily fabricated and installed

FAQ:

1. Why Choose us?

CNBM is a stated own company, provide the guarantee for the best quality, best service and safety business.

2. How will we guarantee the quality?

a, ISO 9001-2008 quality control system;

b, Strict and regular quality control in production;

c, Inspeciation when loading into container before shippment;

d, Sample stock for one year for quality tracing and record.

- Q: Are FRP pultrusion profiles resistant to wear or abrasion?

- Yes, FRP (Fiber Reinforced Plastic) pultrusion profiles are highly resistant to wear and abrasion. The combination of the reinforcing fibers, typically glass or carbon, and the plastic resin matrix creates a material that is incredibly durable and can withstand heavy usage. The pultrusion process also ensures a homogeneous structure with fibers evenly distributed throughout the profile, further enhancing its resistance to wear and abrasion. Additionally, FRP pultrusion profiles can be engineered with specific additives or surface treatments to further enhance their resistance to wear and abrasion, making them suitable for a wide range of applications in various industries, such as construction, transportation, and marine.

- Q: Can FRP pultrusion profiles be used in architectural or decorative applications?

- Yes, FRP pultrusion profiles can definitely be used in architectural or decorative applications. FRP, which stands for Fiber Reinforced Polymer, is a composite material that combines strong fibers, such as glass or carbon, with a polymer resin matrix. This combination creates a lightweight, durable, and corrosion-resistant material that is ideal for various applications, including architecture and decoration. FRP pultrusion profiles can be manufactured in a wide range of shapes and sizes, making them highly versatile for architectural and decorative purposes. These profiles can be used to create aesthetically pleasing structures, such as columns, beams, and facades, that enhance the visual appeal of buildings. Additionally, FRP pultrusion profiles can be fabricated to mimic the appearance of other materials, such as wood or metal, allowing for the creation of decorative elements that blend seamlessly with the overall design. Furthermore, FRP pultrusion profiles offer several advantages over traditional materials commonly used in architecture and decoration. They are lightweight, which makes them easier to handle and install, reducing labor costs. They are also highly resistant to corrosion, weathering, and UV radiation, ensuring long-lasting performance in outdoor applications. Additionally, FRP profiles can be customized to meet specific design requirements, including color, texture, and surface finish, providing endless possibilities for creative expression. In summary, FRP pultrusion profiles are a viable option for architectural and decorative applications. Their lightweight, durable, and customizable nature makes them suitable for a wide range of design needs, while their corrosion resistance ensures longevity and low maintenance. Whether it's for structural support or decorative embellishments, FRP pultrusion profiles offer an excellent choice for enhancing the aesthetics and functionality of architectural and decorative projects.

- Q: Can FRP pultrusion profiles be used in the construction of recreational vehicles (RVs)?

- Indeed, FRP pultrusion profiles find utility in the construction of recreational vehicles (RVs). Renowned for their remarkable strength-to-weight ratio, resistance to corrosion, and durability, FRP pultrusion profiles prove to be an exemplary material for diverse applications, including RV construction. The fabrication of RVs necessitates materials that are both lightweight and robust to ensure fuel efficiency and structural integrity. FRP pultrusion profiles satisfy these requirements as they possess both lightness and high tensile strength, enabling the creation of sturdy and enduring RVs that are also lightweight and easily towed. Furthermore, FRP pultrusion profiles exhibit exceptional resistance to environmental elements such as moisture, UV radiation, and chemicals. Consequently, they prove to be suitable for outdoor applications, including RVs, where exposure to various weather conditions is inevitable. Additionally, FRP pultrusion profiles offer the advantage of effortless customization and adaptability to diverse shapes and sizes, thus meeting the design flexibility essential in RV construction. Beyond serving as structural components like frames, chassis, and supports, they can be employed for interior and exterior panels, floors, and roofs. All in all, the utilization of FRP pultrusion profiles in the construction of recreational vehicles bestows numerous benefits, including strength, durability, lightness, and resistance to environmental factors. These characteristics establish FRP pultrusion profiles as a dependable choice for RV manufacturers aspiring to fabricate high-quality, efficient, and long-lasting vehicles.

- Q: Are FRP pultrusion profiles resistant to chemicals used in pharmaceutical packaging?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are generally resistant to chemicals used in pharmaceutical packaging. FRP pultrusion profiles are made of a combination of reinforced fibers and a polymer resin matrix, which provides them with excellent chemical resistance properties. The polymer resin used in FRP profiles is typically selected to be compatible with a wide range of chemicals, including those commonly used in pharmaceutical packaging. FRP profiles have been extensively used in various industries, including pharmaceuticals, due to their high chemical resistance. They are capable of withstanding exposure to a wide range of chemicals, such as acids, bases, solvents, and other aggressive substances commonly found in pharmaceutical packaging processes. This resistance helps protect the integrity of the packaging and ensures that there is no contamination or degradation of the pharmaceutical products. Additionally, FRP pultrusion profiles are also resistant to corrosion, which is another advantage in the pharmaceutical industry where aggressive chemicals may be present. This resistance to corrosion further enhances the durability and longevity of the FRP profiles, making them a reliable choice for pharmaceutical packaging applications. However, it is important to note that the specific chemical resistance of FRP pultrusion profiles may vary depending on the type and concentration of the chemicals being used. Therefore, it is recommended to consult the manufacturer or supplier of the FRP profiles to ensure their compatibility with the specific chemicals used in pharmaceutical packaging.

- Q: Are FRP pultrusion profiles resistant to high-pressure water jets?

- Yes, FRP pultrusion profiles are generally resistant to high-pressure water jets due to their inherent corrosion resistance and ability to withstand harsh environmental conditions.

- Q: Are FRP pultrusion profiles resistant to hydrochloric acid?

- FRP pultrusion profiles are generally resistant to hydrochloric acid. The corrosion resistance of FRP (Fiber Reinforced Polymer) materials varies depending on the specific resin and fiber used in the manufacturing process. However, most FRP pultrusion profiles are designed to withstand exposure to a wide range of chemicals, including hydrochloric acid. The corrosion resistance of FRP is attributed to the chemical inertness of the resin matrix, which is typically made of polyester, vinyl ester, or epoxy. These resins provide a protective barrier against chemical attack and allow FRP profiles to maintain their structural integrity even in harsh environments. That being said, the level of resistance can vary depending on the concentration and temperature of the hydrochloric acid. In highly concentrated or elevated temperature conditions, the resistance may be reduced. It is always advisable to consult the manufacturer's specifications or seek expert advice to ensure the suitability of FRP pultrusion profiles for specific acid concentration and temperature ranges. Overall, FRP pultrusion profiles are known for their excellent chemical resistance, and they are often chosen for applications where exposure to acids or corrosive environments is expected.

- Q: Are FRP pultrusion profiles electrically conductive?

- FRP pultrusion profiles are typically not electrically conductive. This is because they are made using a combination of fiberglass reinforcement and a thermosetting resin matrix, which provide excellent insulation properties. The fiberglass reinforcement is inherently non-conductive, while the resin matrix further enhances this property. Therefore, FRP pultrusion profiles are commonly used in applications where electrical conductivity is not desired or poses a safety risk. However, it is important to note that certain modifications or additions can be made to the pultrusion process to introduce electrical conductivity if required for specific applications.

- Q: Are FRP pultrusion profiles UV resistant?

- FRP pultrusion profiles are known for their UV resistance. This is because manufacturers use a combination of polymer resin and reinforced fibers, like fiberglass, to create these profiles. These materials naturally possess UV resistant properties, which means that FRP pultrusion profiles can withstand prolonged exposure to sunlight and ultraviolet radiation without getting damaged. For outdoor applications, such as in construction, infrastructure, and marine industries, UV resistance is an important characteristic. However, it's worth noting that the level of UV resistance can vary depending on the specific resin and fiber composition used in the manufacturing process. To get precise information about the UV resistance of FRP pultrusion profiles for a specific application, it's advisable to consult the manufacturer or supplier.

- Q: Can FRP pultrusion profiles be used in the telecommunications industry?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can indeed be used in the telecommunications industry. FRP pultrusion profiles offer several advantages that make them suitable for telecommunications applications. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, which makes them ideal for use in telecommunications infrastructure. These profiles can be used for designing and constructing structures such as antenna mounts, support poles, cable trays, and enclosures. The lightweight nature of FRP profiles allows for easier installation and maintenance, reducing the overall cost and effort involved in setting up and maintaining telecommunications systems. Secondly, FRP pultrusion profiles have excellent corrosion resistance properties. This is particularly important in the telecommunications industry, as infrastructure components are often exposed to harsh weather conditions and environmental factors. Unlike traditional materials like steel or aluminum, FRP profiles do not rust or corrode, ensuring their longevity and reliability in telecommunications applications. Additionally, FRP pultrusion profiles offer electrical insulation properties, which is crucial in the telecommunications industry. These profiles do not conduct electricity, making them suitable for applications where electrical grounding or isolation is required. This feature ensures the safety of telecommunications equipment and personnel. Furthermore, FRP pultrusion profiles can be customized to meet specific project requirements. They can be engineered to have specific dimensions, shapes, and load-bearing capacities as needed. This flexibility allows for the design and fabrication of telecommunications infrastructure that meets the specific demands of each project. In summary, FRP pultrusion profiles are well-suited for use in the telecommunications industry due to their lightweight, high strength, corrosion resistance, electrical insulation properties, and customization options. These profiles offer a reliable and cost-effective solution for various applications within the telecommunications sector.

- Q: Can FRP pultrusion profiles be used in the construction of industrial flooring?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of industrial flooring. FRP pultrusion profiles are made from a composite material that consists of a combination of strong fibers, typically glass or carbon, and a polymer resin. This combination of materials provides exceptional strength, durability, and corrosion resistance, making FRP profiles highly suitable for industrial flooring applications. One of the main advantages of FRP pultrusion profiles is their high strength-to-weight ratio. This makes them lighter and easier to handle compared to traditional materials such as steel or concrete. Additionally, FRP profiles are non-conductive and non-magnetic, which can be beneficial in certain industrial environments. FRP pultrusion profiles are also highly resistant to various chemicals, moisture, and UV radiation, making them ideal for use in harsh and corrosive environments. They do not rust or corrode like steel and are not affected by moisture or rot like wood, ensuring long-lasting performance and minimal maintenance requirements. Furthermore, FRP profiles can be customized and manufactured in different shapes, sizes, and load-bearing capacities to meet specific industrial flooring requirements. They can be designed to withstand heavy loads, impact, vibration, and other dynamic forces commonly encountered in industrial settings. In summary, FRP pultrusion profiles offer numerous advantages that make them suitable for the construction of industrial flooring. Their high strength, durability, corrosion resistance, and customizable nature make them a reliable and cost-effective choice for industrial flooring applications.

Send your message to us

FRP Molded Grating For All Kinds Of Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 20000m2 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords