FRP Pultrusion Profiles:Corrosion Resistant and Fire Resistant FRP Gratings with Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

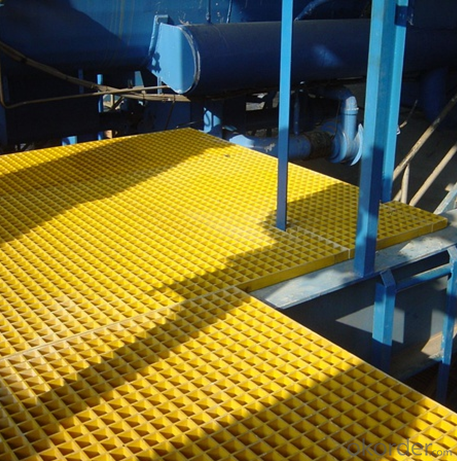

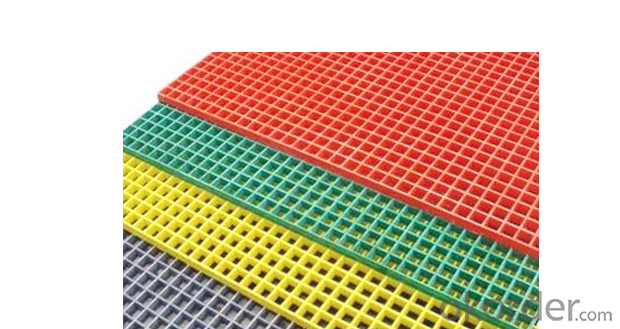

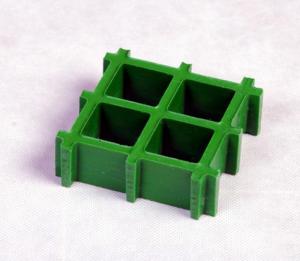

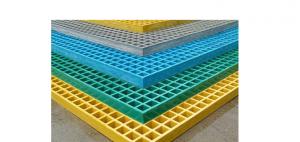

FRP Molded Grating is a structural panel which uses high-strength E-Glass roving as reinforcing material, thermosetting resin as matrix and then casted and formed in a special metal mold. It provides properties of light weight, high strength, corrosion resistance, fire resistance and anti-skid. FRP Molded Grating is widely used in oil industry, power engineering, water & waste water treatment, ocean survey as working floor, stair tread, trench cover, etc. and is an ideal loading frame for corrosion circumstances.

Feature

l Corrosion Resistance

l Fire Resistance

l Light Weight & High Strength

l Safety & Anti-slip

l Electrical Insulating

l Aging Resistance

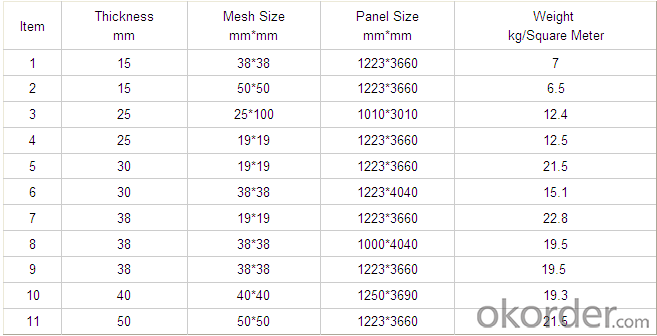

Specification

Advantage

1) coated with prevent aging layer

2) excellent insulating performance

3) no maintenance

4) high strength

5) long service life

6) easy installation

Application

l Power plants, substation equipment enclosures, antimagnetic, anti-static,to prevent small animals into the equipment failure, as there is electricity facilities and without power interval intervals.

l In high voltage electrical equipment for power line work, in order to prevent workers go wrong location, charged interval or near electrically charged equipment to dangerous distance.

l Pool railings in sewage treatment industry

l Corrosive chemical industry equipment around the fence

l All kinds of building maintenance section

FAQ

1. How about the documents after shipment?

After shipment, we ll send all original documents to you by DHL, including Packing List.Commercial Invoice, B/L, and other certificates as required by clients.

2. How long is the delivery time?

Usually it takes 10-25days after receipt of the deposits or L/C, and it also depends on the quantity of your order.

3. How's the payment?

Telegraphic Transfer(T/T) or Letter of Credit(L/C)

4. Do You Arrange Shipment?

Yes, dear esteemed customers, for FOB or CIF price, we will arrange shipment for you. For EXW price, clients need to arrange shipment by themselves or their agents.

5. How is the package?

Usually, we arrange the standard out-package for exporting.

PROCESS

FACTORY

- Q: Can FRP pultrusion profiles be used in telecommunications applications?

- Telecommunications applications can utilize FRP pultrusion profiles, which offer a range of advantages that render them suitable for such infrastructure. To begin with, these profiles possess the desirable combination of being lightweight and strong, making them an excellent choice for supporting antennas, cable trays, and equipment racks. Their high strength-to-weight ratio enables easier installation and transportation while providing the necessary structural support. Moreover, FRP pultrusion profiles display corrosion resistance, a crucial characteristic for telecommunications applications. Given the exposure of telecommunications infrastructure to harsh environments like moisture, chemicals, and extreme temperatures, FRP's non-corrosive properties guarantee long-term durability and reliability, distinguishing it from traditional materials such as steel or wood. Additionally, FRP pultrusion profiles offer electrical insulation properties, which are vital in telecommunications applications. By not conducting electricity, they ensure safety in areas where electrical equipment is present. This feature prevents electrical interference and preserves the integrity of the telecommunications system. Furthermore, FRP pultrusion profiles can be customized to meet specific design requirements, as they can be manufactured in various shapes and sizes. This flexibility allows for the efficient design of telecommunications infrastructure, making FRP pultrusion profiles suitable for a wide range of applications within the industry. In conclusion, FRP pultrusion profiles prove to be well-suited for telecommunications applications due to their lightweight yet strong nature, corrosion resistance, electrical insulation properties, and customization possibilities. These attributes guarantee their reliability in supporting and protecting telecommunications infrastructure.

- Q: The manufacturing process of FRP products?

- 1, hand paste production method; 2, spray forming method; 3, fiber winding process; 4, molding process and molding process; 5, pultrusion method.

- Q: Are FRP pultrusion profiles resistant to fuels?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles are highly resistant to fuels. Due to their inherent corrosion resistance and non-reactive nature, FRP pultrusions can withstand exposure to a wide range of fuels, including gasoline, diesel, and aviation fuels, without deteriorating or losing their structural integrity. This makes them suitable for various applications in industries such as automotive, aerospace, and oil and gas, where resistance to fuel exposure is crucial.

- Q: What are the quality control measures for FRP pultrusion profiles?

- Quality control measures for FRP pultrusion profiles involve a series of steps and processes to ensure the products meet the desired standards. These measures include: 1. Raw material inspection: The first step is to verify the quality of the raw materials used in the pultrusion process. This includes checking the properties and specifications of the fiberglass, resin, additives, and other components. 2. Process control: Throughout the pultrusion process, various parameters need to be monitored and controlled. This includes maintaining consistent temperature, pressure, and resin content during the impregnation, forming, and curing stages. 3. Sample testing: Regular sampling is conducted during production to assess the quality of the profiles. These samples are tested for mechanical properties, dimensional accuracy, and surface finish to ensure they meet the required standards. 4. Visual inspection: Each profile is visually inspected to identify any defects, such as cracks, voids, delamination, or surface imperfections. Visual inspection helps to identify any irregularities that may affect the structural integrity or aesthetics of the profiles. 5. Mechanical testing: Profiles are subjected to mechanical testing to assess their strength, stiffness, and other mechanical properties. This involves conducting tests like flexural testing, tensile testing, impact testing, and compression testing. The results are compared to the specified requirements to determine if the profiles meet the necessary standards. 6. Quality documentation: Proper documentation is maintained throughout the manufacturing process, including records of raw material specifications, process parameters, test results, and inspection reports. This ensures traceability and provides a reference for quality assurance. 7. Non-destructive testing: In addition to mechanical testing, non-destructive testing techniques, such as ultrasonic testing or X-ray inspection, may be used to identify internal defects or inconsistencies without damaging the profiles. 8. Quality audits: Regular internal and external audits are conducted to assess the effectiveness of the quality control measures and ensure compliance with relevant industry standards and regulations. By implementing these quality control measures, manufacturers can ensure that FRP pultrusion profiles meet the required specifications, resulting in reliable and high-quality products.

- Q: Are FRP pultrusion profiles resistant to oil and grease?

- FRP (Fiber Reinforced Plastic) pultrusion profiles are generally known for their excellent resistance to oil and grease. The combination of fibers, typically glass or carbon, with a polymer resin matrix results in a material that is inherently resistant to many chemicals, including oil and grease. This resistance is attributed to the non-reactive nature of the polymer resin, which prevents the oil or grease from penetrating the material and causing damage. Additionally, the pultrusion manufacturing process used to produce FRP profiles further enhances their resistance to oil and grease. During the pultrusion process, the fibers are impregnated with the resin and then pulled through a heated die, where the resin is cured. This creates a strong, uniform material with a dense surface that is less porous and more resistant to chemical penetration. It is important to note that the specific resistance of FRP pultrusion profiles to oil and grease can vary depending on the type of resin used and the specific application conditions. In some cases, specialized resin formulations can be used to further enhance the oil and grease resistance of FRP profiles, ensuring suitability for even more demanding environments. Overall, FRP pultrusion profiles are generally considered to be highly resistant to oil and grease, making them an excellent choice for applications where exposure to these substances is expected. However, it is always recommended to consult with the manufacturer or supplier to ensure that the specific FRP profile being used is appropriate for the intended application and chemical exposure.

- Q: How do FRP pultrusion profiles perform in high humidity environments?

- FRP (Fiber Reinforced Polymer) pultrusion profiles perform exceptionally well in high humidity environments. The inherent properties of FRP, such as its corrosion resistance and moisture resistance, make it an ideal material for applications that are exposed to moisture or high humidity. One of the key advantages of FRP pultrusion profiles is that they are non-porous, which means they do not absorb moisture. This characteristic prevents the profiles from swelling, warping, or rotting when exposed to high levels of humidity. Unlike traditional materials like wood or steel, FRP does not degrade or lose its structural integrity in humid conditions. Additionally, FRP pultrusion profiles have a high resistance to chemicals, including the corrosive effects of moisture and humidity. This resistance to corrosion is due to the composite nature of FRP, which combines a matrix material (typically a resin) with reinforcing fibers, such as glass or carbon fibers. This combination provides excellent resistance to water and moisture-induced corrosion, ensuring the long-term performance of FRP profiles in high humidity environments. Furthermore, FRP pultrusion profiles offer excellent dimensional stability, even under extreme temperature and humidity variations. They do not expand or contract significantly, maintaining their shape and structural integrity in diverse environmental conditions. This stability makes FRP profiles suitable for applications in coastal regions, wastewater treatment plants, chemical processing plants, and other environments where humidity levels are high. Overall, FRP pultrusion profiles are specifically engineered to withstand harsh conditions, including high humidity environments. Their non-porous nature, resistance to corrosion, and dimensional stability make them a reliable and durable choice for various applications in humid climates.

- Q: Can FRP pultrusion profiles be used in the construction of modular storage systems?

- Yes, FRP (Fiber Reinforced Polymer) pultrusion profiles can be used in the construction of modular storage systems. These profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for supporting heavy loads and ensuring long-term performance in storage applications. Additionally, their modular nature allows for easy assembly and customization, making them a viable option for constructing versatile and efficient storage systems.

- Q: Can FRP pultrusion profiles be used in the construction of agricultural structures?

- Yes, FRP pultrusion profiles can be used in the construction of agricultural structures. FRP pultrusion profiles are lightweight, durable, and resistant to corrosion, making them suitable for various agricultural applications such as greenhouse framing, livestock enclosures, and storage sheds. They offer excellent strength-to-weight ratio and can withstand harsh environmental conditions, making them a reliable choice for agricultural construction.

- Q: Can FRP pultrusion profiles be used in the construction of water slides?

- Yes, FRP pultrusion profiles can be used in the construction of water slides. FRP stands for Fiber Reinforced Polymer, which is a composite material that offers several advantages for water slide construction. Firstly, FRP pultrusion profiles are lightweight yet incredibly strong, making them ideal for creating the structural components of water slides. These profiles have high strength-to-weight ratios, meaning they can withstand the dynamic loads and forces experienced in water slide applications without adding excessive weight to the structure. Secondly, FRP pultrusion profiles are highly resistant to corrosion, which is essential for water slide construction. Water slides are constantly exposed to water, chemicals, and harsh weather conditions, which can cause traditional materials like steel to corrode and degrade over time. FRP profiles, on the other hand, are inherently corrosion-resistant, ensuring the longevity and durability of the water slide. Additionally, FRP pultrusion profiles offer design flexibility. They can be customized to various shapes and sizes, allowing for the creation of unique and exciting water slide designs. These profiles can also be easily molded, allowing for the incorporation of various features such as slides, curves, and drops to enhance the overall water slide experience. Lastly, FRP pultrusion profiles have excellent thermal insulation properties. This is beneficial for water slides as it helps maintain the temperature of the water, preventing excessive heat loss or gain. This feature enhances the comfort and enjoyment of users while reducing energy consumption for heating or cooling the water. In conclusion, FRP pultrusion profiles are well-suited for water slide construction due to their lightweight, high strength, corrosion resistance, design flexibility, and thermal insulation properties.

- Q: Can FRP pultrusion profiles be used in the construction of safety barriers?

- Yes, FRP pultrusion profiles can be used in the construction of safety barriers. FRP (Fiber Reinforced Polymer) pultrusion profiles offer high strength-to-weight ratio, corrosion resistance, and durability, making them suitable for safety barrier applications. They can withstand harsh environmental conditions and provide excellent impact resistance, making them an ideal choice for ensuring safety in various industries such as construction, transportation, and infrastructure.

Send your message to us

FRP Pultrusion Profiles:Corrosion Resistant and Fire Resistant FRP Gratings with Modern Shape

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m²

- Supply Capability:

- 500000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords